TM 9-2330-356-14

b.

Cleaning and Inspection.

WARNING

Particles blown by compressed ah' can be

dangerous. Be sure to direct air stream away

from-the user and other personnel in the area.

(1) Use low pressure, moisture-free compressed

air to remove dust and residue.

(2) Carefully inspect all parts for wear, cracks,

breakage, or other defects.

(3) Rotate bearings by hand and check for

binding or wear.

c.

Assembly.

(1) If slip ring end bearing (13, fig. 7-64) has been

removed, press a new bearing in place from the outside of

the slip ring end housing (31). Bearing should be installed

with seal facing in toward the slip rings. When properly

installed, the manufacturer's part number stamped on the

end of the bearing will be facing toward the outside of the

housing. Bearing should seat against lip on inside end of

bearing bore. After bearing is installed, apply a small

amount of SRI 2 grease to rollers.

(2) Install insulating bushings (27, 28,29, and 30,

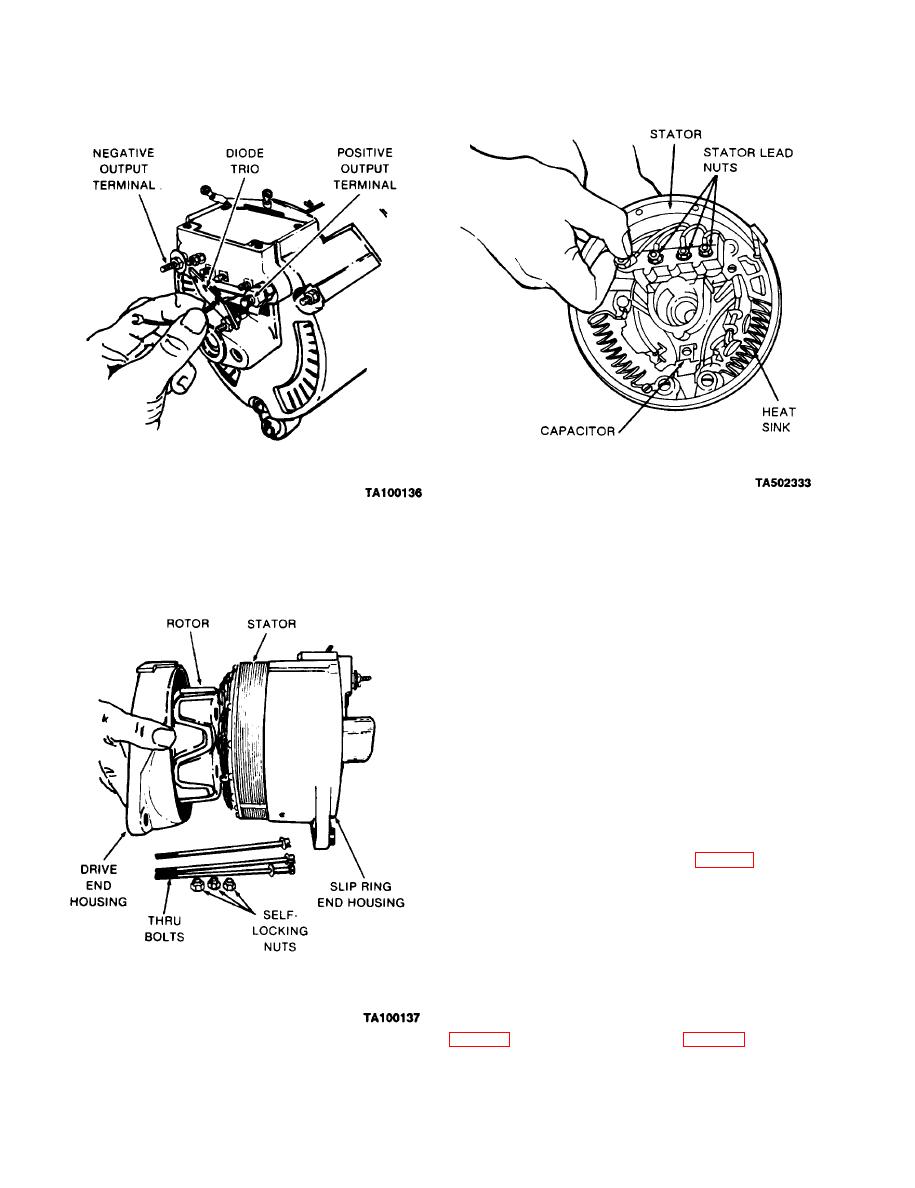

Figure 7-66. Dismantling Alternator.

7-60