TM 9-2330-356-14

indicates that a leak is present. The pressure must remain

above 250 psi for at least 30 seconds.

Test, After Rebuilding.

a.

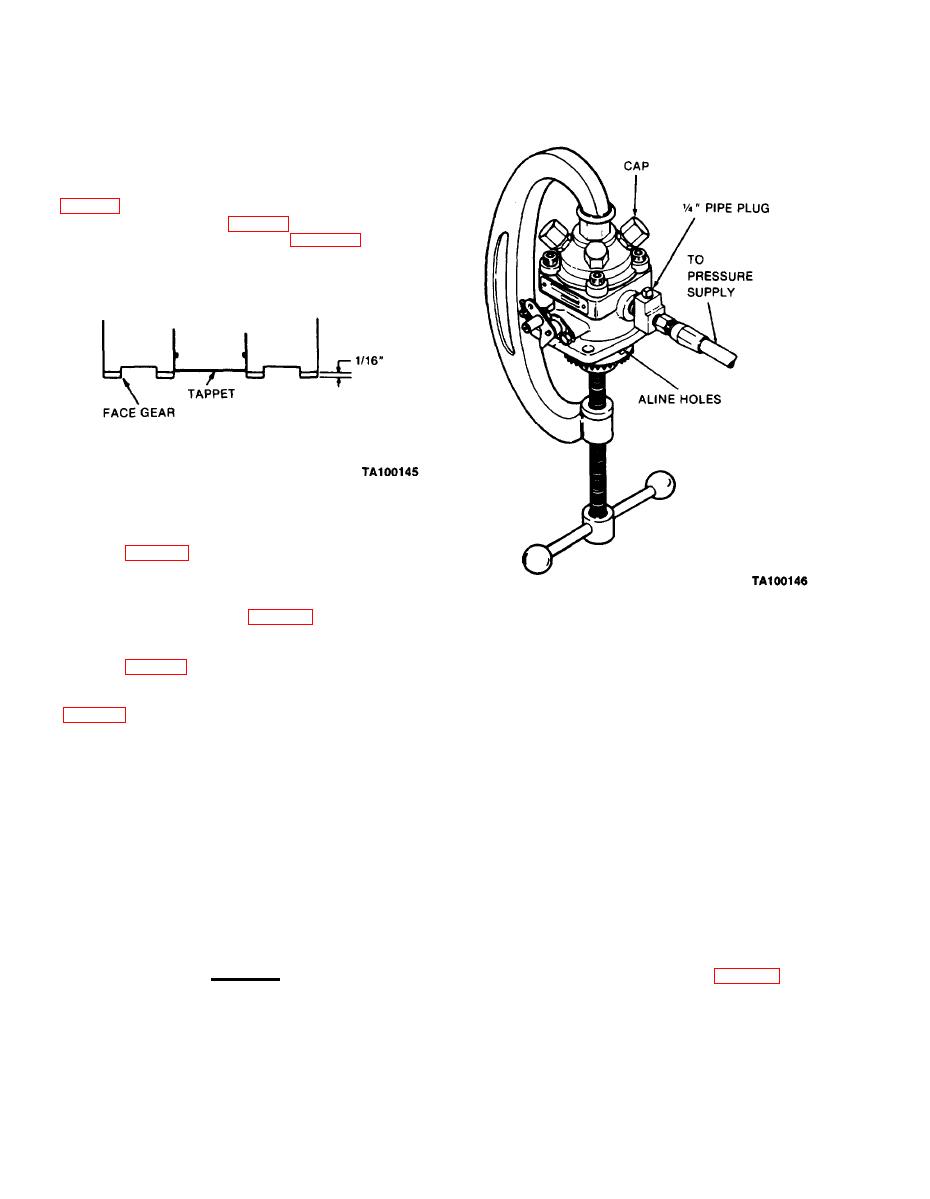

(1) Turn pump upside down and depress tappet

with thumb. Tappet should recede 1/16-inch into face gear

gear, plunger sleeve pin (5, fig. 7-46) is improperly alined.

Disassemble pump and re-aline pin (para 7-69).

(2) Remove the overflow valve assembly from

the fuel outlet hole in the pump housing. Install a 1/4-inch

pipe plug (fig. 7-75) into the fuel outlet hole.

(3) Secure the pump close to a nozzle test stand.

(9) Visual inspection should be as follows:

(5) Install C-clamp on injection pumps to retain

(a) Check for leakage by the head locating

face gear (fig. 7-75).

screw (13, 7-46).

(6) Aline holes in face gear and housing

(b) Fuel leakage at the control unit (4)

indicates that either the O-ring (33) is damaged or the

control unit is defective. Replace entire injection pump.

NOTE

(c) Check for leakage of fuel around the

A fuel inlet stud can be fabricated with a 1/4-18

face gear (28). If leakage is evident, disassemble pump and

NPT pipe die. High pressure tubing must be

inspect O-ring (19). If O-ring is damaged, replace injection

used between test stand and the pump

pump.

assembly. Always ensure that all external

connections are tight and that the nozzle test

(d) Check for fuel leakage between top of

stand is in good order.

housing and head flange. Disassemble and check O-ring.

If O-ring is damaged, replace injection pump.

(7) Connect the nozzle test stand to the fuel inlet

b. On Equipment Adjustment and Timing.

hole in the pump housing.

(1) Timing. Time the injection pump to the

engine by using the proper thickness timing button

CAUTION

between the pump plunger and tappet (fig. 7-76). Use

method 1 when replacing an old pump if the port closing

Do not exceed a pressure of 400 psi.

dimensions and button number of the old pump were

recorded. Use method 2 if the dimensions are-lost; an old

pump is being timed, or when replacing either camshaft or

(8) Slowly operate the nozzle test stand until a

crankshaft.

pressure of 400 psi is achieved. A rapid drop in pressure