TM9-2330-368-14 & P

4-22. TIRE REPAIR

a. Repair tires in accordance with TM-9-2610-

200-24.

b. Replace defective rims.

4-23. TIRE MOUNTING

Materials/Tools

Tire and rim lubricant (item 5, app E)

Wiping rag (item 10, app E)

Tire irons T47A (reference 7, app B, section III)

Tire iron T46B (reference 8, app B, section III)

Locking jaw pliers (reference 9, app B, section III)

3 lb. cross peen hammer

Tire mounting pedestal, part number EX-1002

(refer to app G)

CAUTION

If mounting face of wheel is not flat or

ball seats are damaged, do not put wheel

in service.

Tire mounting is a three-person operation.

Remove nut and washer from tire valve.

a.

Insert valve stem from inside rim, through

valve hole and seat valve stem base against

rim. Install washer and nut on stem and

tighten nut.

Lubricate tire bead liberally with tire and

b.

rim lubricant.

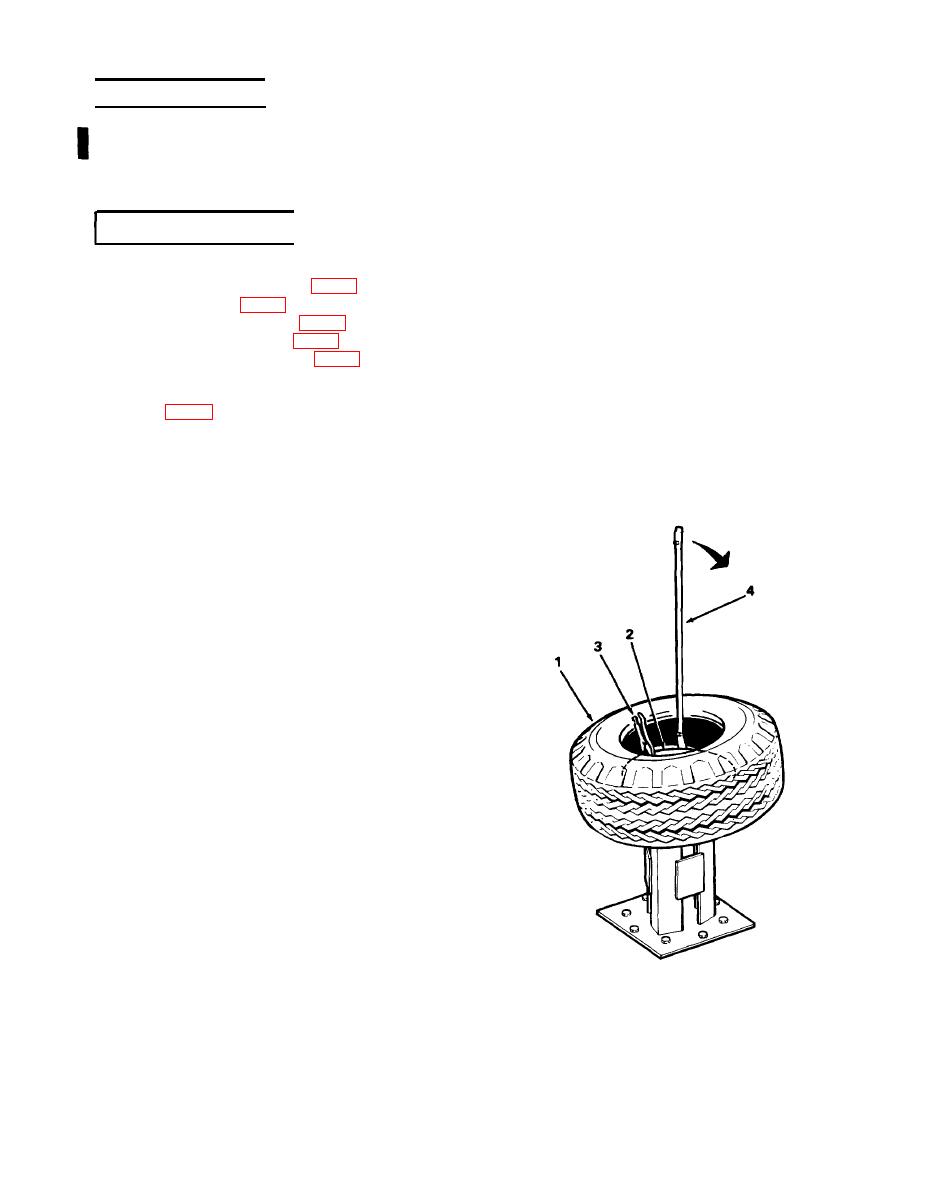

Position tire (1) on wheel (2) at an angle

c.

so part of lower bead is below wheel rim

on side opposite valve stem. Clamp locking

jaw pliers (3) on rim directly opposite

valve stem. The pliers will keep lower

bead from coming over rim when mount-

ing.

d. Insert curved end of long tire iron (4) be-

tween lower bead and rim approximately

8 to 10 inches from position of locking

jaw pliers (3). Push down on tire where

pliers are located and lever tire iron to

force lower bead down over rim. Make

sure that lower bead at location of pliers

TA252190

goes into groove in wheel rim.

4-43

Change 1