TM9-2330-368-14 & P

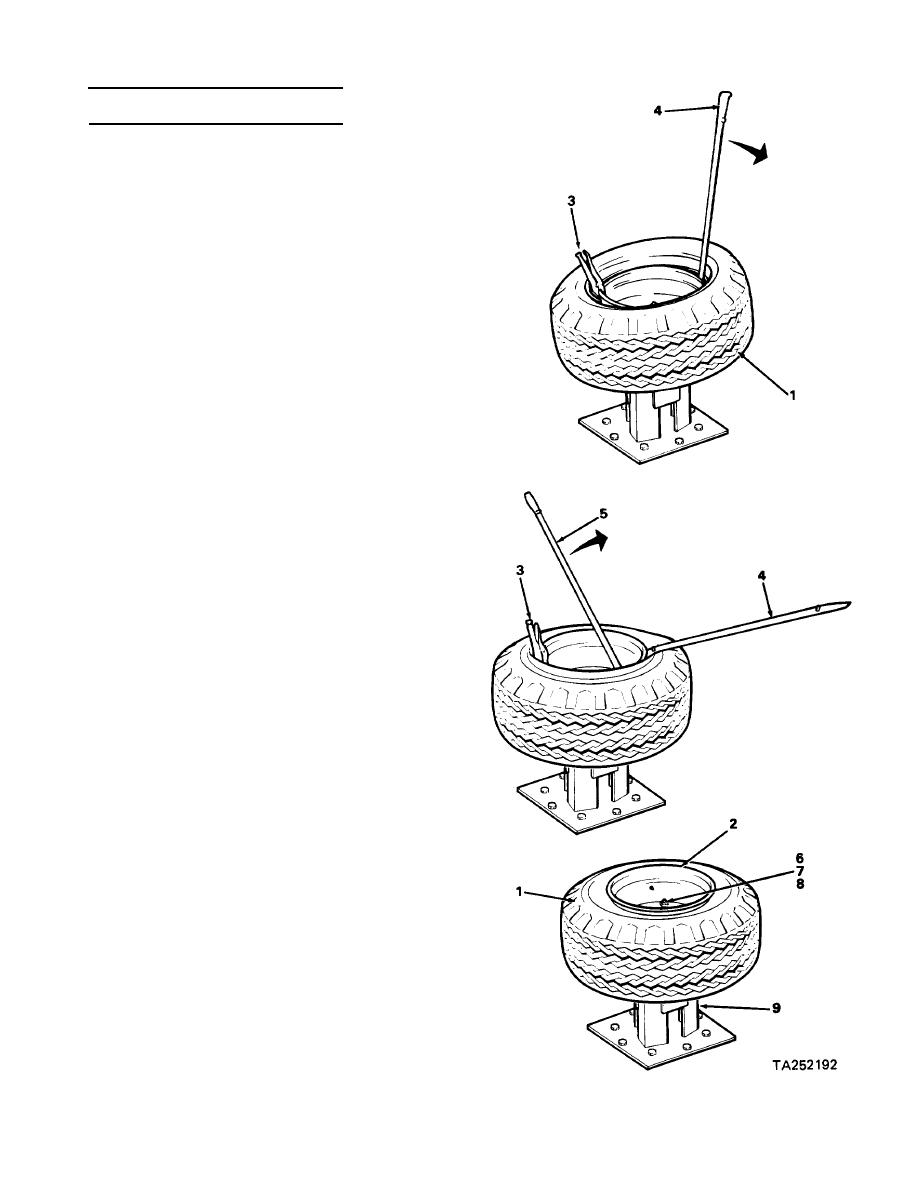

4-23. TIRE MOUNTING (cont)

i.

Position tire (1) so part of upper bead is

below rim on side opposite valve stem.

Clamp locking jaw pliers (3) on rim on side

opposite valve stem.

Insert curved end of long tire iron (4) be-

j.

tween upper bead and rim approximately

10 to 12 inches from position of locking

jaw pliers (3). Push down on tire (1) where

pliers are located and lever tire iron to

force upper bead down over rim.

Hold tire iron (4) down. Insert curved end

k.

of other tire iron (5) between bead and

rim several inches from tire iron (4), and

lever another bite of bead down over rim.

l.

Repeat step k using tire irons alternately

and working around bead and rim until

entire upper bead is down over rim.

m. Remove tire irons (4 and 5) and pliers (3).

n. Remove hex nuts (6), flat washers (7) and

hex bolts (8). Remove wheel (2) and tire

(1) from pedestal (9).

o. Inflate Tire.

(1) Stand tire upright and hold while apply-

ing air. Applying body weight to top

of tire will usually seat tire beads and

tire will inflate.

CAUTION

Excessive pressure will damage tire

internal structure.

NOTE

If tire beads do not seat during infla-

tion, put a bead expander around out-

side center of tire to compress tire

and force beads to seat. If a bead ex-

pander is not available, use load binder

and chain. Apply only enough pressure

on tire to lightly seal beads against rim.

(2) Inflate tire to 85 psi (4.07 KPa).

4-45