TM 9-2330-381-14

4-48.

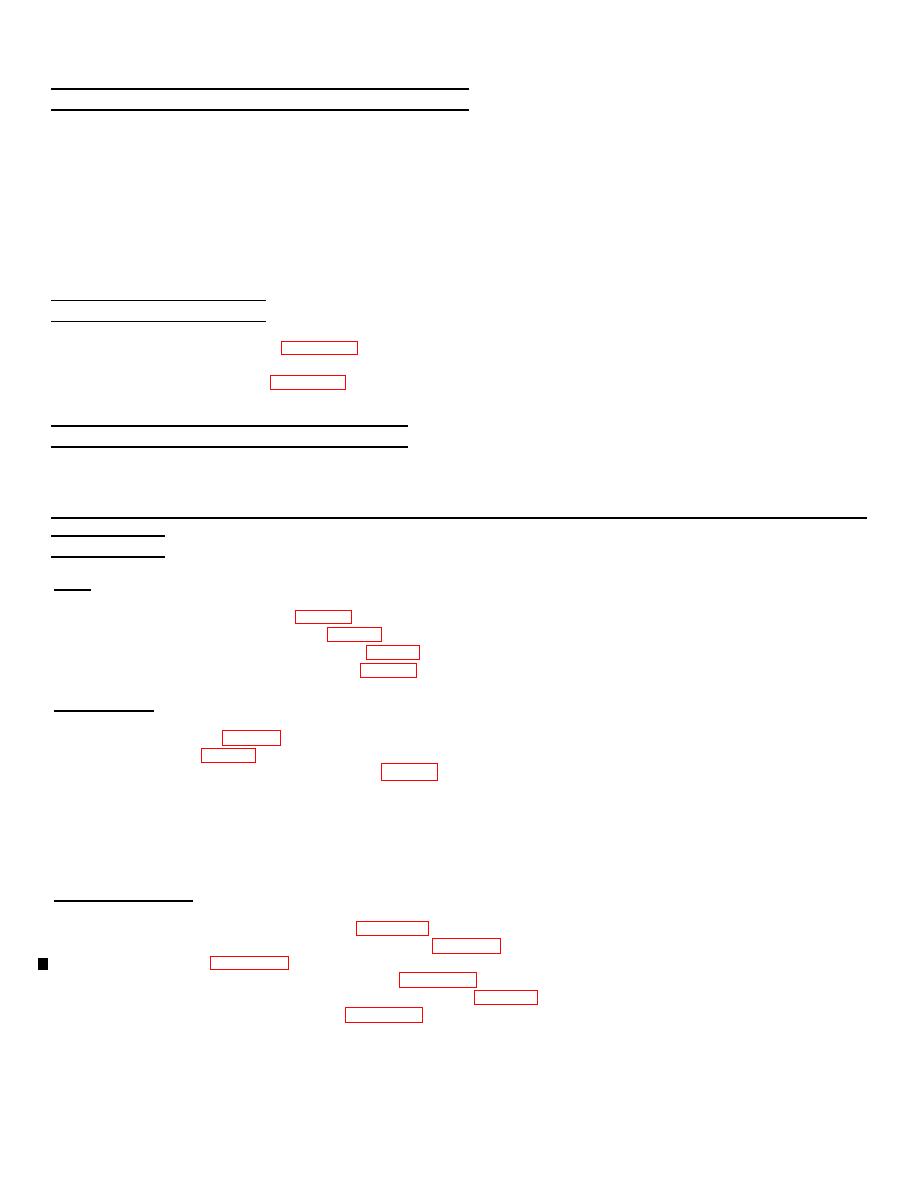

GOOSENECK PNEUMATIC INSTALLATION (CONT)

NOTE

Insert nearby nonmetallic hoses into clamp loops as the clamp loops are

installed/secured to gooseneck.

5.

Aline and install five clamp loops (5) and secure in place with locknuts (4).

6.

Apply pipe sealant to threads of three nonmetallic hoses (1, 2, and 3) and aline and install three nonmetallic

hoses.

FOLLOW-ON MAINTENANCE

1.

Couple tractor/semitrailer (para. 2-24).

2.

Drive tractor/semitrailer (para. 2-25) and check for proper brake operation and air leaks.

4-49.

PLATFORM PNEUMATICS INSTALLATION

This task covers:

a. Removal

c. Repair

b. Inspection

d. Installation

INITIAL SETUP

Tools

General mechanics tool kit, item 16, appx. B

Socket set, deepwell, 1/2" drive, item 18, appx. B

Torque wrench, 3/8" drive 0-200 in-lb, item 18, appx. B

Torque wrench, 1/2" drive 0-170 lb-ft, item 18, appx. B

Materials/Parts

Cap and plug set, item 5, appx. E

Pipe sealant, item 18, appx. E

Electrical tiedown strap(s) (as required), item 27, appx. E

Lockwasher (4)

Locknuts (12)

Lockwasher (5)

Lockwasher (18)

Cotter pin (10)

Equipment Condition

Platform adjusted to 50 inch (127 cm) height (para. 2-19)

Suspension isolation valves closed at four corner bogies (para. 2-6)

Brake chambers caged (para. 2-33)

Gooseneck lowered to lowest position, if uncoupled (para. 2-18)

All five air tanks drained by pulling on air tank lanyards (item 3, para. 2-8)

Platform steps and service covers removed (para. 4-59)

4-216 Change 1