TM 9-2330-381-14

4-118. BII PREPARATION

NOTE

The BII components require very little surface preparation since many of the

surfaces are painted. However, due to extensive use and handling, some paint

chipping will occur, allowing rust and/or corrosion to start. All items must be

thoroughly cleaned to remove all rust and corrosion, and touch-up paint applied as

needed to restore surface protection.

These procedures apply to both Level A and Level B. Each item, as it is prepared,

must be tagged for identification.

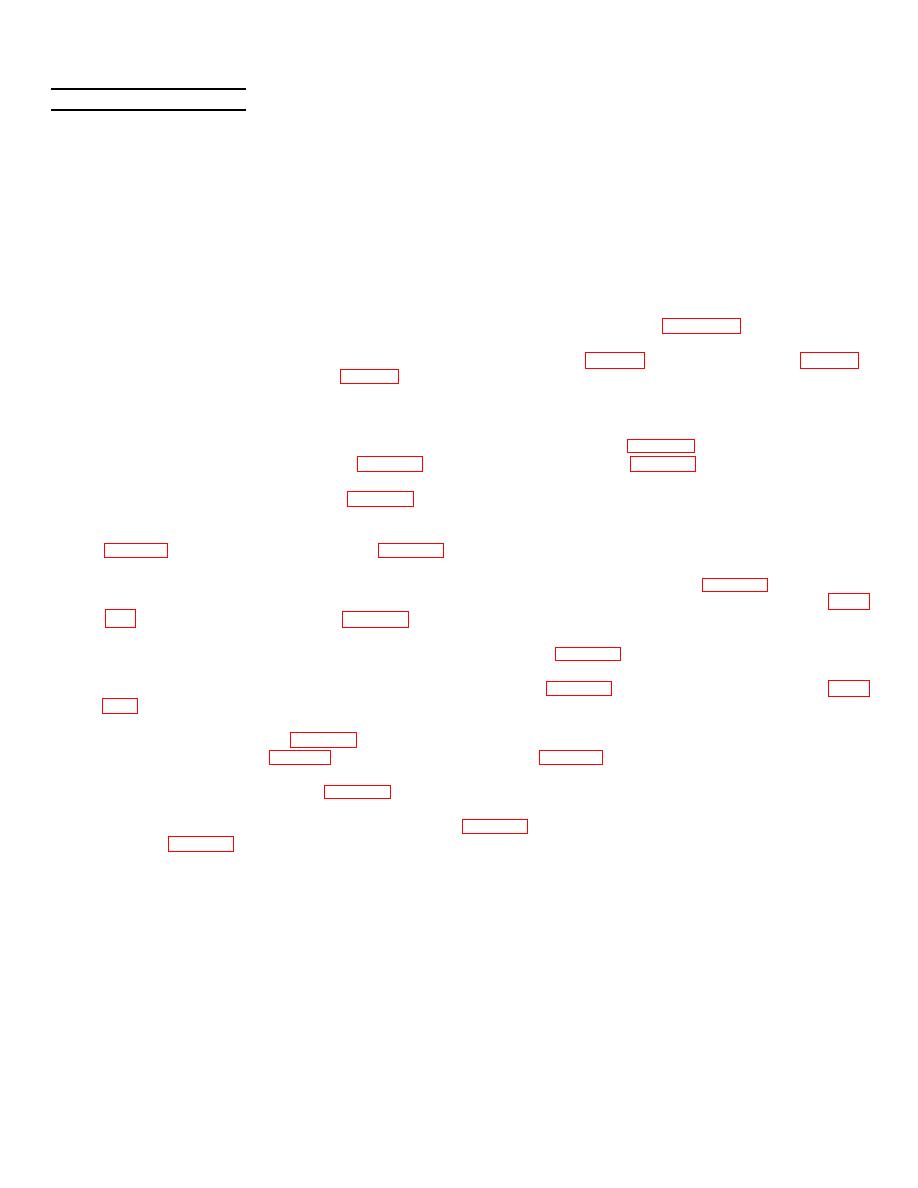

a. Remove all BII items from platform stowage compartment (5) and inventory against appendix C listings.

b. Remove all rust and corrosion from BII using a wire brush (item 16, appx. B), crocus cloth (item 6, appx. E),

general purpose detergent (item 8, appx. E), and water.

c. Spot paint surface areas where paint has worn and/or chipped off.

d. Coil all chain assemblies as small as possible and identify and tag (item 12, table 4-1) each chain. Wrap each

chain with cardboard cushion (item 4, table 4-1) and secure with tape (item 13, table 4-1).

e. Place each shackle in a bag (item 1, table 4-1) and heat seal bag.

f. Wrap individual ends of crowbar, ISOL handle extension bar, and wrecking bar with cardboard cushion (item 4,

g. Coil manila rope to approximately 10-inch (25 cm) diameter. Place rope in a bag (item 1, table 4-1) and heat seal

bag. Place bag in a 10-1/2-inch x 10-1/2-inch x 6-inch (27 x 27 x 15-1/2 cm) fiberboard container (item 3, table

h. Place each of the 12 ISO container locks in individual bags (item 1, table 4-1) and heat seal bags.

i. Wrap each load binder with cardboard cushion material (item 4, table 4-1) and secure with tape (item 13, table

j. Apply preservative (item 9, table 4-1) to unpainted surfaces of the sledge hammer. Wrap head of hammer with

barrier material (item 2, table 4-1) and secure with tape (item 13, table 4-1).

k. Place cheater bar in bag (item 1, table 4-1) and heat seal bag.

l. Place all remaining tools into individual bags (item 1, table 4-1). Heat seal each bag and attach identification tags

(item 12, table 4-1).

4-532