TM 9-2330-384-14&P

4-45. CHANGING TIRES (Con't).

NOTE

Inner tire (3) and spacer (12) must be worked evenly so that they do not

become jammed.

If removed, install inner tire (3) with rim mounting flange side facing out.

(2)

Install spacer (12) on wheel.

(3)

Install outer tire (3) with rim mounting flange side facing in and with valve stem (8) positioned

(4)

as close to 180 degrees away from inner tire valve stem as possible.

Install five rim clamps (5) and

(5)

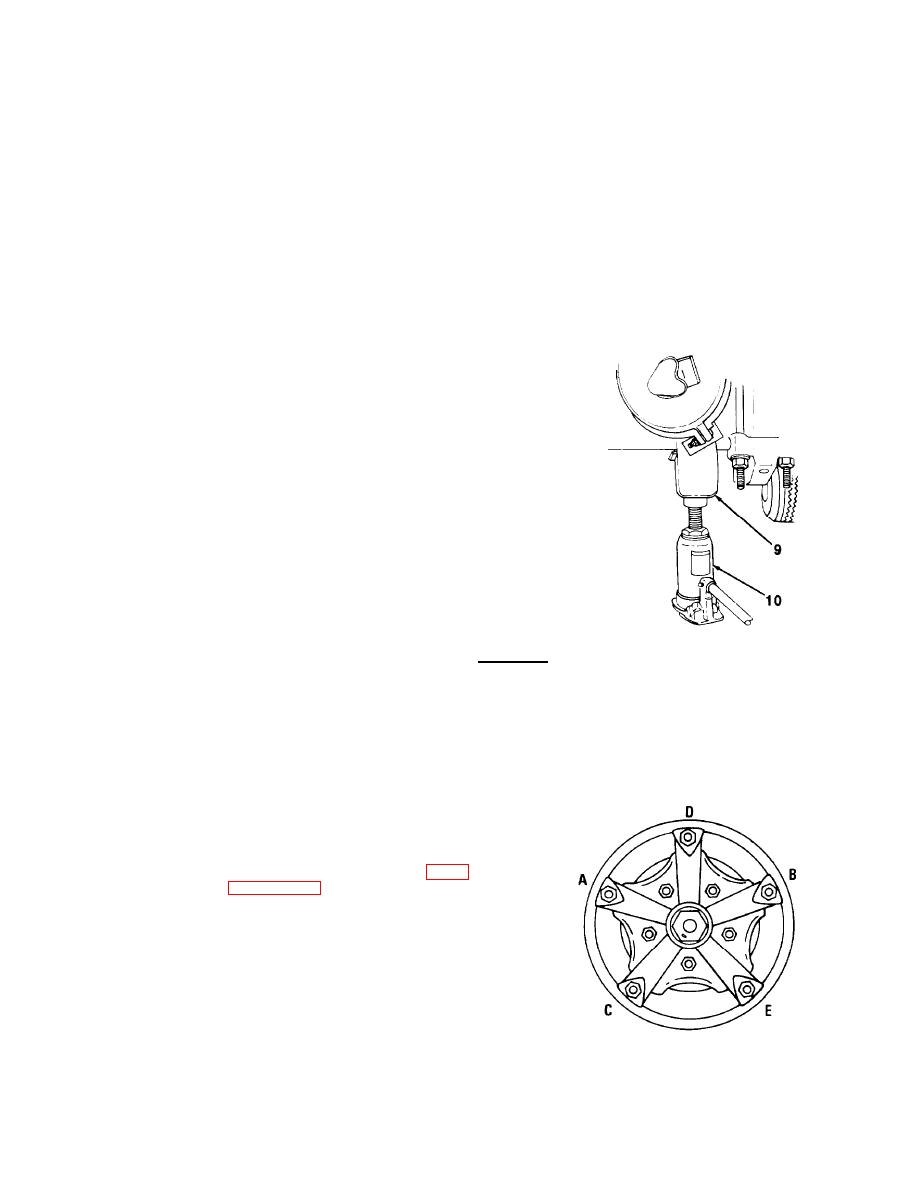

wheel nuts (6). Tighten wheel nuts

in crisscross pattern shown.

Lower semitrailer to ground. Re-

(6)

move jacking block (9) from trac-

tor jack (10) and stow in cabinet.

Stow tractor jack in tractor.

CAUTION

It is important that torque of wheel nuts (6) and rim alinement be checked.

Insufficient torque can cause rim slippage, resulting in broken valve stems,

worn parts, and damaged tires. Excessive torque can cause damage by

stripping wheel studs, collapsing a spacer, or forcing rims into an out-of-

round condition. Improper rim alinement will cause tires to wobble and wear

unevenly.

Torque wheel nuts (6) in crisscross

(7)

pattern shown to 250 lb.-ft. (339

Nm).

Check rim alinement (see para-

(8)

4-145