TM 9-3405-215-14&P

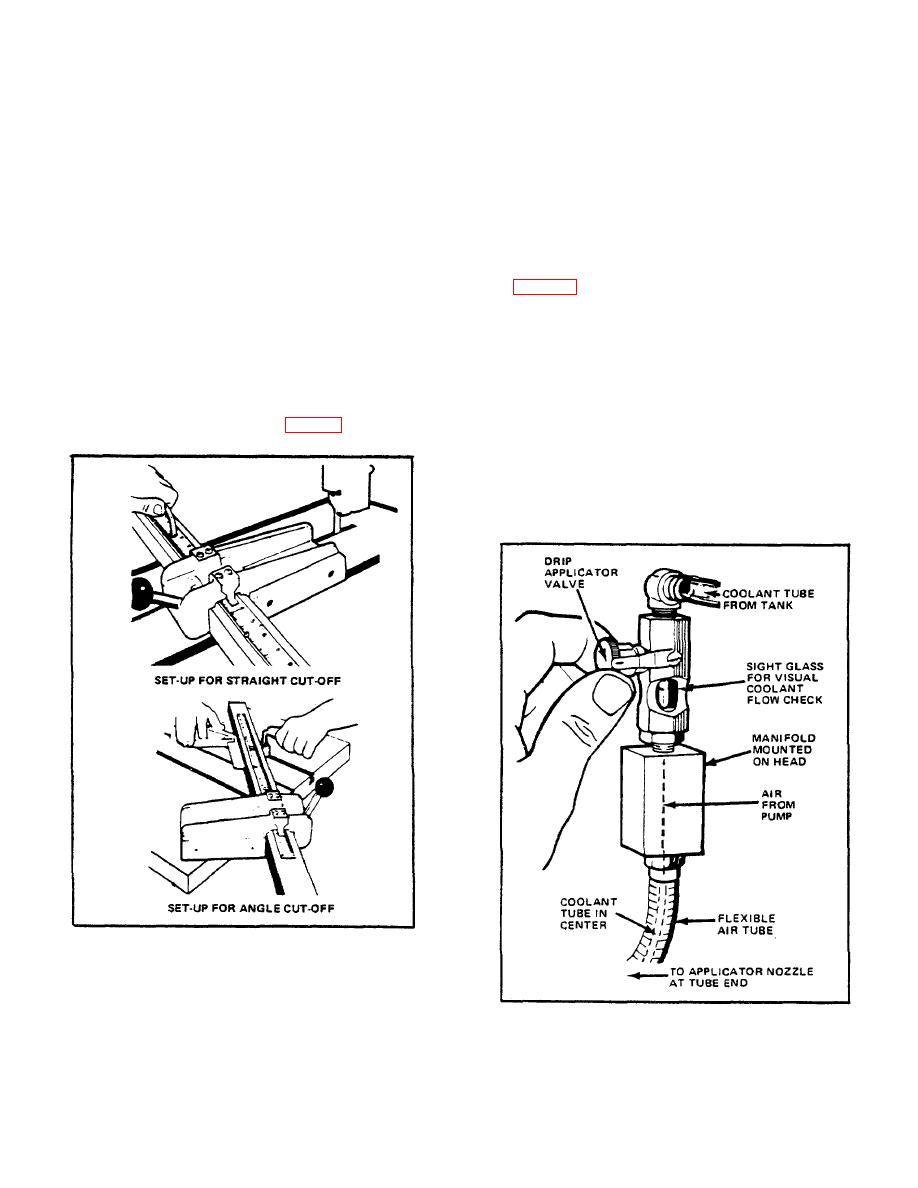

UNIVERSAL CALIBRATED WORK FIXTURE

machine head back to drip applicator valve with sight

glass. Coolant next enters manifold and is directed into

This accessory clamps to the table, can be set up for

a nylon tube which passes through flexible air tube. Air

straight or angle cut-off, and holds the workpiece in

and coolant are mixed at nozzle end to form a fine mist.

position while it is moved into the saw band. For straight

Bend applicator tube to direct mist stream onto blade

sawing, place fixture on table at required distance from

teeth and work.

band. Loosely install T-nuts and screws. Square fixture

to table by lining up one moveable stop edge with one

Regulate mist with drip applicator valve. Count drops

table slot edge. Tighten screws. Saw kerf into bar 1/16

visible through sight glass. Normal mist adjustment

to 1/8 inch (1.5 to 3.2 mm) deep to allow cutting

produces approximately one coolant drop per second.

completely through workpiece. Set adjustable table

See Fig. 33. Check for a fine, consistent mist by

stops to prevent deeper sawing into work bar after cut

directing stream onto a metal surface. Intermittent

completion.

stream with coolant spurts generally indicates a manifold

air leak. Check all joints.

For angle sawing, remove right T-nut and screw.

Loosen left screw, turn fixture to desired angle, and

Clean nozzle and coolant bottle when necessary.

tighten left screw. Mount collar (behind bar) loosely on

Replace nylon center tube by disassembling flexible

T-nut with socket-head screw.

Bring collar snugly

tubing. Insert new center tube. Make sure all joints are

against bar and tighten screw. See Fig. 32.

sealed and tight. Coil applicator tube a few times, and

trim excess nylon so that it is flush with nozzle end.

See Lubrication Chart for recommended coolant

products. Clogging may occur if wax-based or other

coolants are used.

FIG. 32. UNIVERSAL CALIBRATED WORK FIXTURE.

MIST COOLANT APPLICATOR

Coolant is delivered from a 1-quart (0.95-liter) bottle on

FIG. 33. ADJUSTING MIST COOLANT.

20