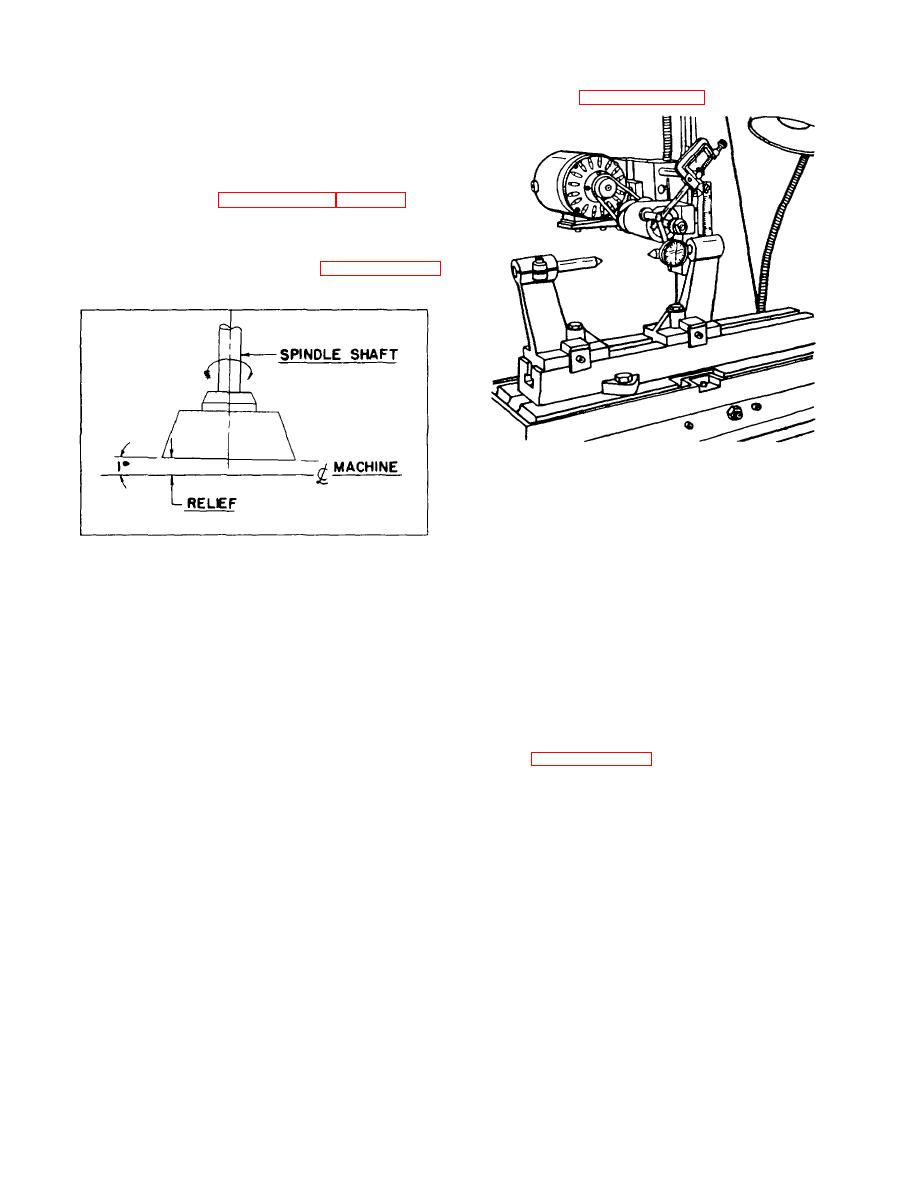

bracket slightly and reposition against stop pin. Check

this alignment. To align centers, mount a dial indicator on

position on indicator. Traverse table back and forth. Dial

the wheel guard support shaft and let the indicator touch

indicator should not vary more than .002.

the centers. See Illustration No. 5.

The grinding wheel spindle and column should

next be adjusted to permit grinding wheel relief. Loosen

hex cap screws (dia No. 36 of exploded view drawing No.

2) and rotate column toward front of machine when work-

head is used as shown in Illustration No. 2 and No. 3.

The object here is to relieve the cup wheel so that

it will not drag on the surface just ground by the leading

edge of the grinding wheel. See drawing illustration No. 4.

ILLUSTRATION NO. 5

LINING UP THE CENTERS

Do not tighten hold-down screw (dia No. 8 and No. 9).

Leave them slightly loose so that the sub-table can be

moved or rotated about the shoulder screw. Next, move

ILLUSTRATION NO. 4

the sub-table back and forth as required to achieve an

RELIEVING THE GRINDING WHEEL

indicator reading of (.001) one thousandth. Tighten the

sub-table hold down screws and re-check dial indicator

HEIGHT SCALE

reading. Now the center stand can be positioned to

receive the work to be ground. If desired, a scribed line

The height scale should be set so that the pointer reads

may be placed on the right hand end of sub-table and the

"O" when the center of the grinding wheel spindle is at the

grinder table if these lines are carefully made, it will not be

same elevation as the center of the work-head collet

necessary to re-indicate sub-table each time it is used for

adapter. This will permit setting the grinding wheel at the

most applications. For very close work, the table should

proper height when grinding relief angles on the outside

always be indicated in for each job. When grinding work

diameter of some cutters.

with a taper, the sub-table can be rotated as needed up to

45. See illustration No. 6.

CENTER STANDS AND SUB-TABLE

GRINDING WHEELS

The sub-table is mounted directly on top of the grinder

table using the shoulder screw (dia No. 8 of exploded view

The 374 Router Bit Grinder uses either two or three inch

drawing No. 4) and two (2) hex cap screws and washer

diameter grinding wheels and in resinoid or vitrified bond.

(dia No. 9 and No. 11.)

It is important to always use grinding wheel blotters with

these grinding wheels. A blotter should be placed on both

The center stands can be positioned anywhere along

sides of the grinding wheel. In the case of diamond

the sub-table, depending on work to be ground. When

grinding wheels, no blotters are necessary and should not

placing center stands on the sub-table, always snug up on

be used. When tightening the

the take-up tabs (dia No. 5) before you tighten hold-down

screws (dia No. 10). This will permit the center stands to

guide on one side of the machined T-slot and, after

alignment, the center stands can be moved without losing

4