OPERATION (Cont'd)

vented by a slip clutch. A loud sound produced by this

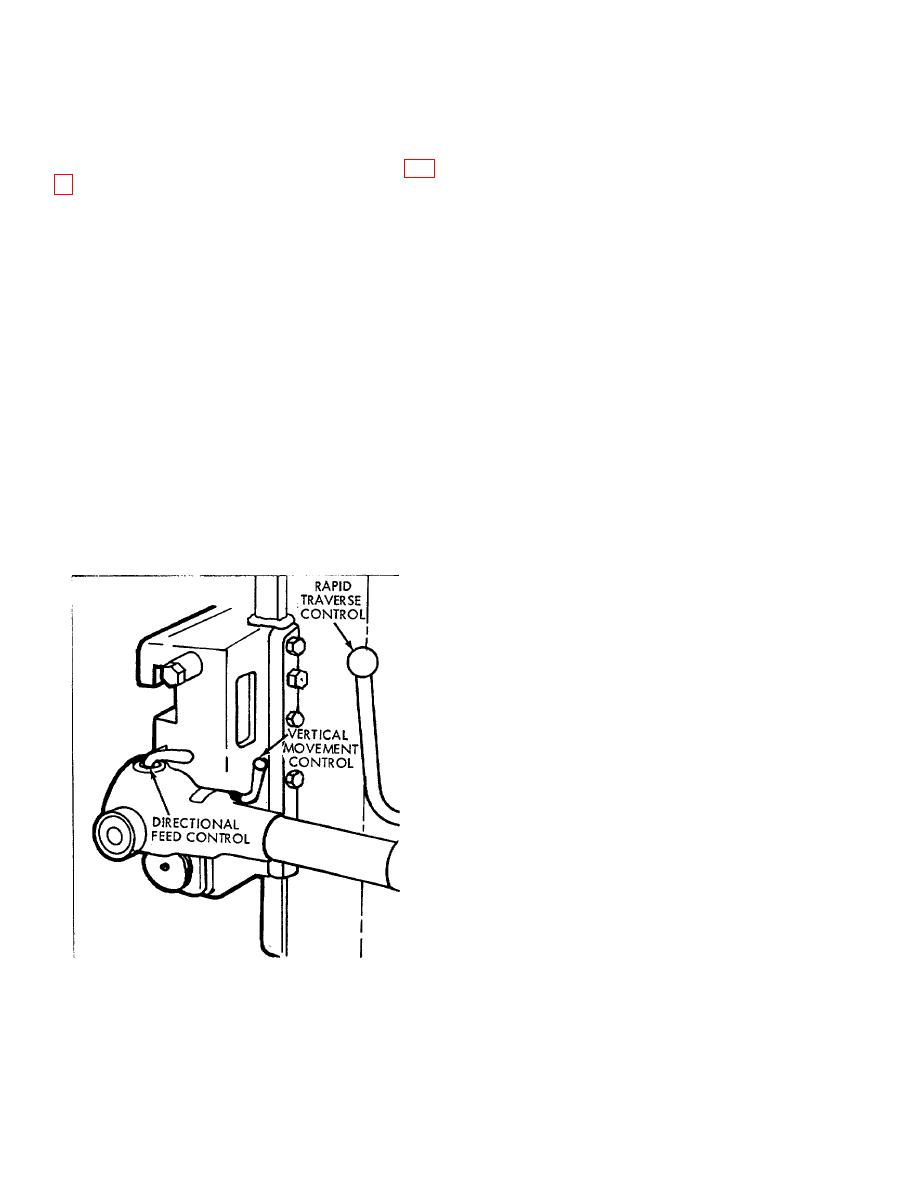

ADJUST RAPID TRAVERSE

clutch warns of reaching the limit.

Horizontal and vertical rapid traverse is always

available whether the machine is running or idle, as long

NOTE: This clutch does not protect the machine at

as the motor is operating. Traverse is engaged by

pulling outward on the rapid traverse control. (See Fig.

the upper limit of vertical traverse. Caution

should therefore be exercised in positioning

the directional feed control and is indicated on an

the crossrail to prevent damage to the ram

adjacent plate.

or tool head.

To traverse horizontally: Place the directional feed

control in the direction desired (jogging the rapid

To traverse vertically: First loosen table support

traverse control handle to engage clutch teeth) and

clamp and remove the stress block. Then loosen the

place the vertical movement control in its lower position

rail clamp (F) and revolve rail clamp (G) several

(which is the standard position for feeding and

revolutions counterclockwise. (Do not loosen the jam

traversing horizontally). Pull outward on the rapid

nuts because they are adjusted to hold the crossrail

traverse control to traverse.

slideably to the frame.) Place the directional feed control

in the vertical traverse direction desired (jogging the

THE DIRECTION OF HORIZONTAL RAPID

rapid traverse control handle to engage clutch teeth)

TRAVERSE IS ALWAYS OPPOSITE TO THE

and place the vertical movement control in its upper

DIRECTION OF THE FEED SET. Releasing the control

position. Pull outward on the rapid traverse control to

disconnects the traverse and automatically reinstates

traverse. Releasing the control disconnects the traverse

the feed.

mechanism.

Always place directional feed control in neutral

The table is raised or lowered by rapid traverse to

when positioning work table horizontally by hand to

its approximate working position. This position should

avoid damaging the feed mechanism. Overtravel past

be as high as possible consistent with safety so as to

either end limit of horizontal rapid traverse or feed is

minimize overhang of tool. Final adjustment of the tool

pre-

in relation with the work is made by setting the tool

head.

When table is in position place vertical movement

control in its lower position, then secure rail with clamp

(F) and rail clamp (G), reset table support and adjust

stress block to lock the front of the table.

ADJUST FRONT SUPPORT

On machines equipped with a front support, always

use both the support and the stress block. After

clamping the front support, insert the stress block

directly under the table on the inside of the front

support. If the table is set at or near its lowest position,

or if machine is equipped with a universal table, the

stress block will not fit beneath the table and should be

applied to the clamp outside of the support.

The vise may be swiveled by loosening the four

clamping bolts of bottom plate. Tighten bolts securely

before beginning to shape.

Figure 2.

4