TM 9-3431-254-14&P

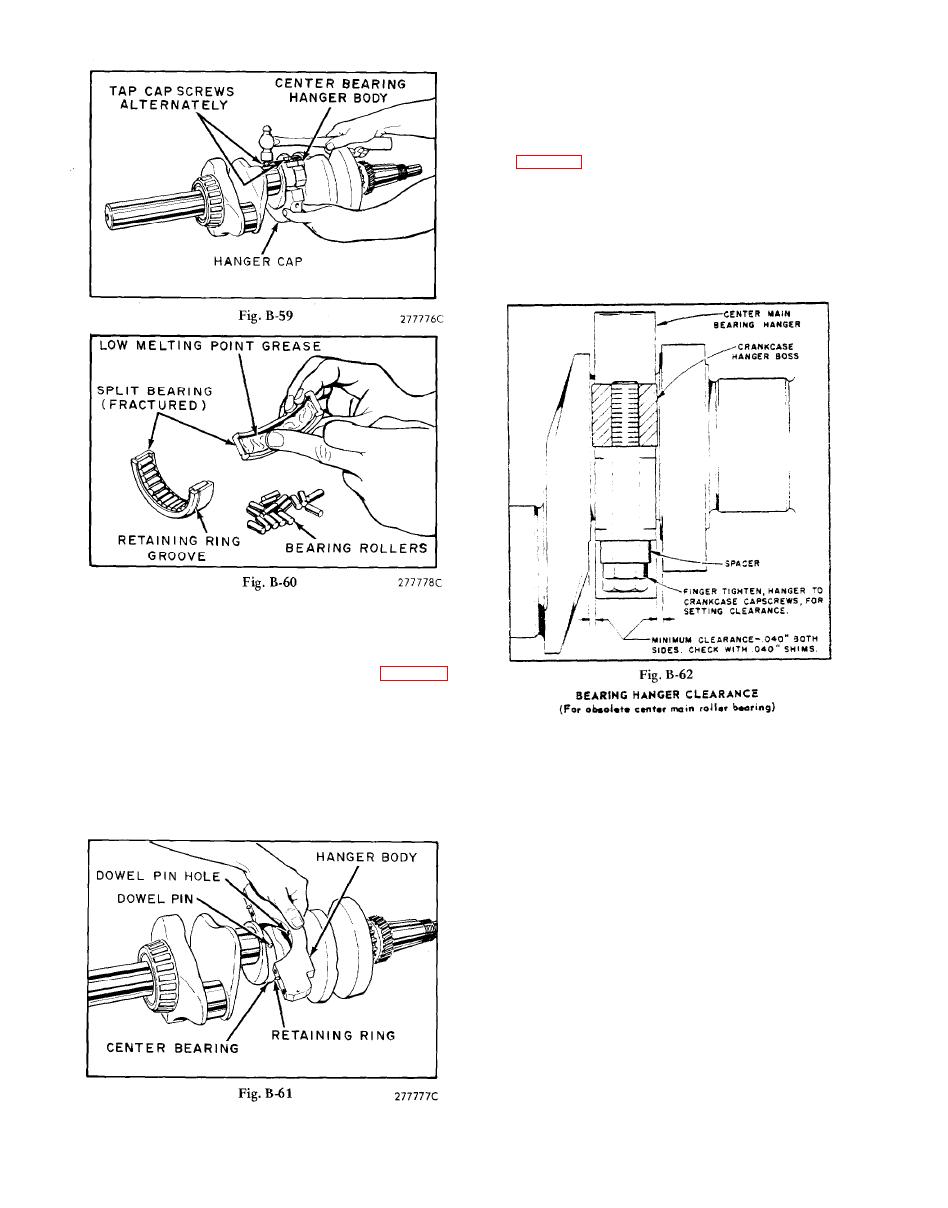

Secure bearing hanger to crankcase after crankshaft

end play is adjusted. Note: Beginning with engine

serial No. 4052826, the capscrews for mounting the

bearing hanger to crankcase were lengthened to 3

inches, and a spacer added under the screw heads,

see Fig. B-62. Thus all 4 screws for the center main

bearing hanger assembly are the same, minimizing

the possibility of improper assembly. Install hanger

capscrews, with spacers, finger tight and position

bearing hanger so that there is a minimum of .040

inch clearance between the sides of the bearing han-

ger and crankshaft cheeks. Tighten hanger to crank-

case capscrews, 60 foot pounds torque.

together with retaining ring. The ring must overlap

both mating edges of the bearing. Insert shouldered

dowel pin into either hole of the bearing race and

place the hanger body against the bearing so the

dowel slips into the dowel pin hole, see Fig. B-61.

Hold hanger body against bearing, place cap in posi-

tion and draw the capscrews finger tight until the 2

dowels are just entering holes. With a hand wrench,

alternately turn each screw to turns to evenly

draw cap tight to hanger body. Torque capscrews to

40 foot pounds, alternately in 3 stages; 15, 30 and

40 ft/lbs. A few squirts of oil in the hanger cap oil

hole will help to dissolve the bearing grease.

B-34