TM 9-3431-254-14&P

Slip sleeve over and slightly below top of piston. Ex-

and remove connecting rod cap by tapping lightly on

tension of piston out of sleeve will act as a pilot for

the end of the bolts. Use a brass rod so as not to up-

mounting cylinder. Lubricate cylinder bore and press

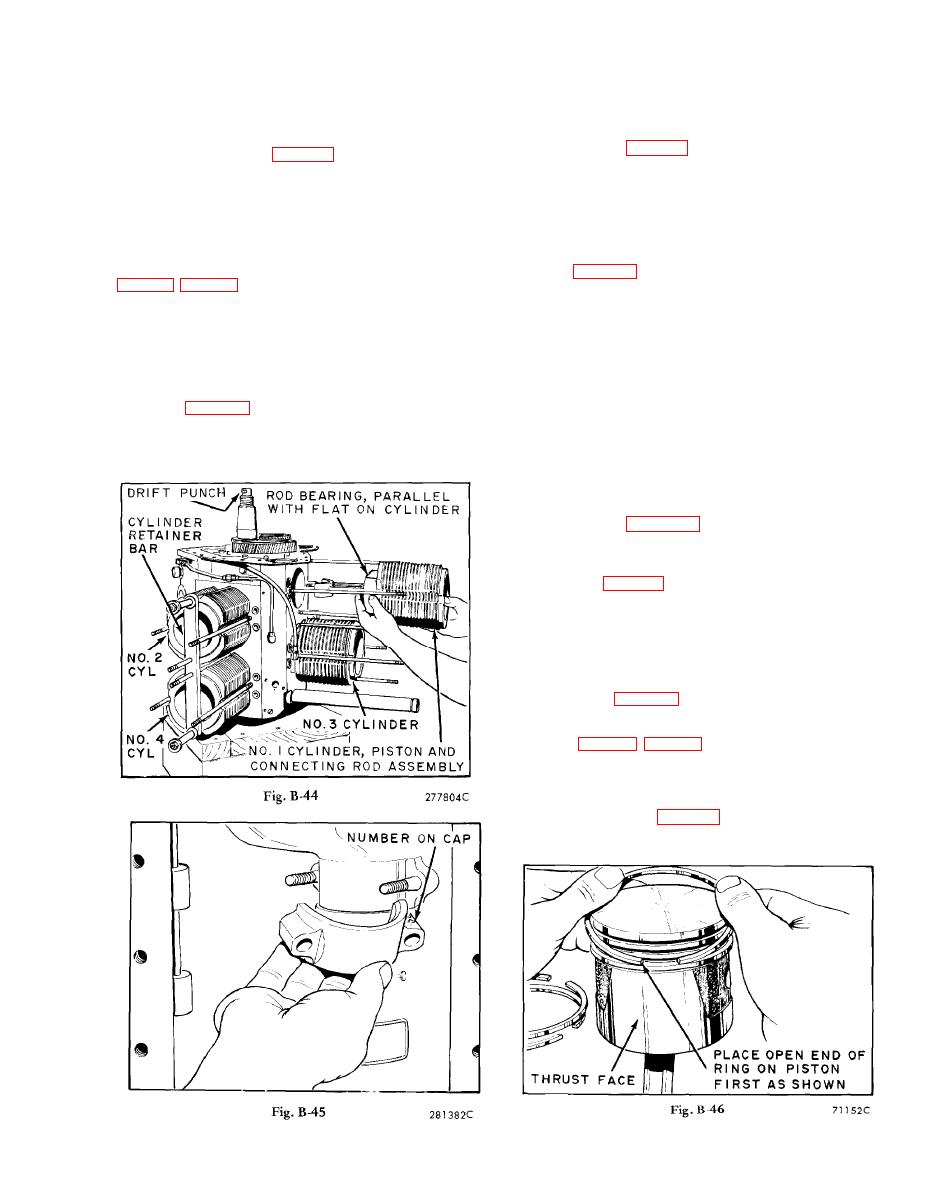

set bolt threads. Remove cylinder retainer bar and

barrel on to piston and against sleeve. Force piston

withdraw cylinder barrel, piston and connecting rod,

into bore by tapping cylinder barrel with a rubber

as illustrated in Fig. B-44. Place cap on rod immediate-

mallet, as illustrated in Fig. B-43. When bottom ring of

ly so that it will not be mismatched in reassembly.

piston is securely in cylinder, lower sleeve and re-

Remove No. 3 cylinder assembly, and then do like-

move thru slot. Continue to press barrel over piston

wise with the No. 2 and 4 cylinder bank.

until it is snug against crankcase. Mount cylinder

studs and remainder of parts per 'Cylinder Head'

Identical numbers are stamped on the side of the rod

paragraphs of reassembly.

with its corresponding cap. These numbers must be

on the same side of the connecting rod in reassem-

CYLINDER, PISTON and CONNECTING ROD

bly. See Fig. B-45. Install new nuts on connecting rod

bolts and torque to 32 foot pounds.

After removing cylinder heads and before attempting

Cylinder barrels should be put back on the crankcase

to loosen connecting rod caps, it is advisable to hold

in the same location they were removed from. Use a

down both banks of cylinder barrels, lest they be-

new gasket at bottom of barrel. Clean all dirt and

come loosened and damaged when rotating the crank-

chaff from between fins and bottom of flange.

shaft. This can be accomplished by means of a steel

If the cylinders are worn more than .005 inch over-

retainer bar and the cylinder hold down studs, as

size, they should be reground and fitted with over-

shown in Fig. B-44.

size pistons and rings. This work should be done by

Insert a drift punch in crankshaft crank pin hole, and

an authorized service station.

turn shaft over so that the nuts for the No. 1 connect-

If in the opinion of the service station attendant, a

ing rod cap are accessible. Take off the 2 nuts, loosen

chrome re-ring is necessary, use

piston ring set indicated in Parts List Section.

If a ring expander tool is not available, install rings

by placing the open end of the ring on piston first,

as shown in Fig. B-46. Spread ring only far enough to

slip over piston and into correct groove, being care-

ful not to distort ring. Assemble bottom ring first and

work upward, installing top ring last. The outer dia-

meter of the too compression ring is chrome plated.

Mount scraper ring with scraper edge down, otherwise

oil pumping and excessive oil consumption will re-

sult. Refer to Fig. B-47 for correct placement of rings

for the V-460D, V-461D and V-465D.

PISTON (Fig. B-48, Fig. B-49)

The piston skirt is cam-ground to an elliptical con-

tour. Clearance between the piston and cylinder must

be measured at the bottom of the piston skirt thrust

face. Refer to Chart, Fig. B-48, for proper clearance.

The thrust face on the piston skirt is 90 from the

axis of the piston pin hole.

B-29