When blade clearance is set for the first time or after new or resharpened blades have been installed, it must be

accomplished through the use of feeler gauges. After the initial setting and calibrating the Blade Clearance Indicators (not

0200 series), subsequent changes can easily be made.

CAUTION - Be careful not to place hands between blades or under holddowns at any time.

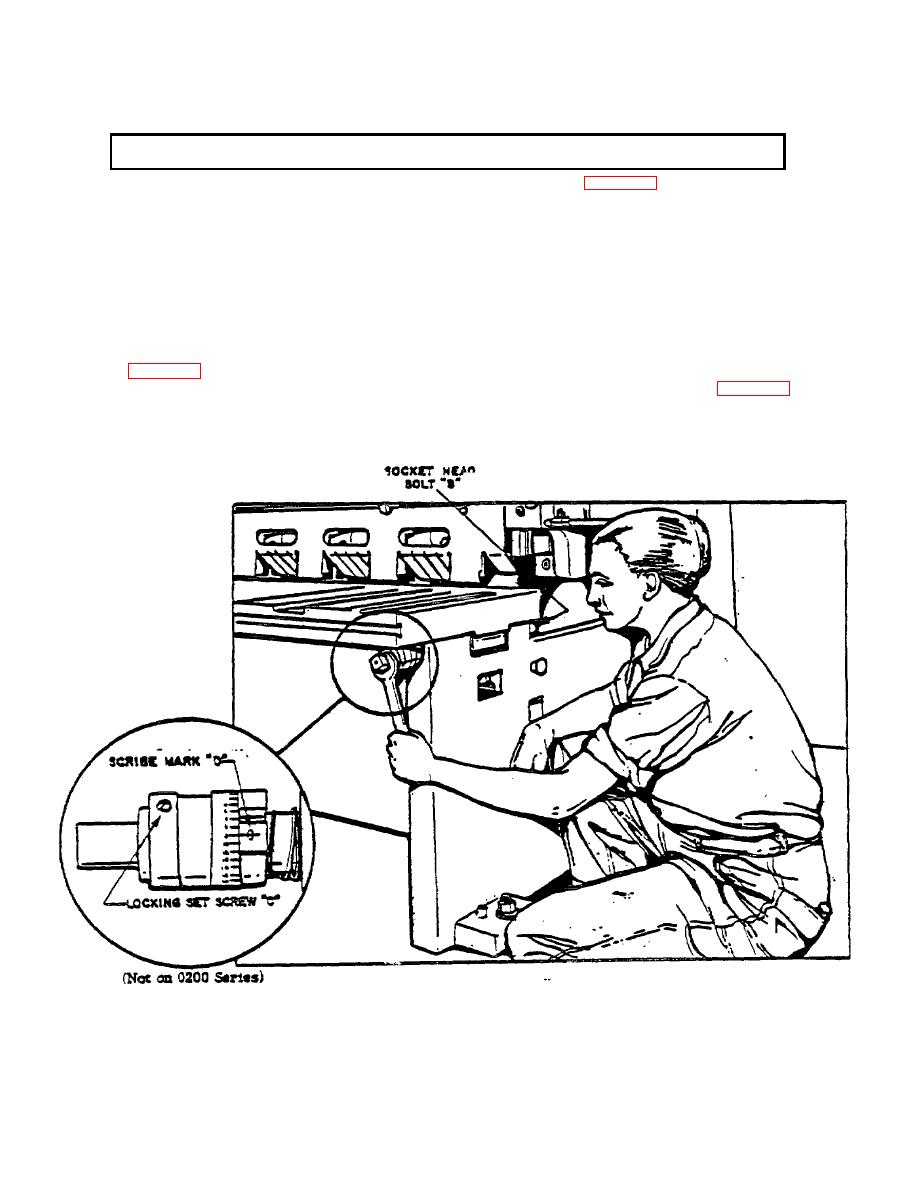

To adjust blade clearance for the first time, loosen Socket Head Bolt (B) (Figure 14) on each end of the table. Jog

the ram down until the blades intersect about 1" from the left end. Using the Blade Clearance Adjustment (on 0200 series,

Socket Head Cap Screw), move the left end of the table and lower blade to the desired clearance. Lock the table with

Socket Head Bolt (B). Further jog the upper blade (making certain there is no interference)until the right end of the blades

intersect approximately 1: from the right end. Adjust this end of the table and lower blade to the exact same clearance as

the left end. Lock this adjustment.

When the proper clearance has been obtained at both ends, bolt (B) should be securely tightened to lock the

adjustment and the Blade Clearance Indicators should be calibrated.

To calibrate the Blade Clearance Indicators (Series 0300, 0400, 0600, 0800, 1000), simply loosen socket headset

screw "C" (Figure 14) and rotate the indicator by hand until the numerals on the indicator are the same as the blade

clearance that has just been set at each end of the blade. It should coincide with scribe mark (D) (Figure 14). Retighten

socket head set screw "C". This calibration must be done on each of the two indicators. Calibrations on the indicators

read in thousandths. If settings less than 0.004: are to be used, use a feeler gauge to obtain accurate settings.

Figure 14. Adjusting the Blade clearance

14