SOF-LOC HOLDDOWN SYSTEM

The Sof-Loc Holddown System provides a means of lowering the holddowns slowly to the work without impact, and

clamping the work to the shear table before the upper knife and backgauge angle start to move. With this system. highly

polished or soft material can be sheared without marking, and excessive noise and vibration from the holddowns are

eliminated.

Your Shear is arranged so that the hydraulic holddowns can be operated with the Sof-Loc Holddown System or with

the standard Hydro-old System.

Hydro-Hold Operation:

Turn the Holddown Selector Switch to HYDRO-HOLD. In this position the Sof-Loc Holddown System is inoperative

and our machine wilt operate in the usual manner with the holddowns being operated entirely by the Hydro-Hold Pump

Case. The machine will operate at the maximum strokes per minute as shown in the specifications. The UP and DOWN

Buttons are inoperative.

Sof-Loc Operation:

Turn the Holddown Selector Switch to SOF-LOC. When the foot switch is depressed, the air solenoid valve on the

air Line to the Sof-Loc Cylinder is opened and the Sof-Loc Cylinder will cause the holddowns to be lowered, without

impact, lightly clamping the work to the table. The pressure switch on the left end of the holddown bar will close and

activate the air clutch, starting the shearing cycle.

When the air clutch is activated, the Hydro-old Pump Case then takes over, quickly increasing the pressure in the

holddowns before the upper blade makes contact with the material.

The approach speed of the Holddowns can be regulated by adjusting the Flo-Control Valve which is located between

the Sof-Loc Cylinder and the Air Solenoid Valve. With the Flo-Control Valve al the way open, the m1achne will operate at

approximately 20% fewer strokes per minute than shown in the specifications. As the Flo-Control Valve is closed, stowing

the approach speed of the Holddowns, the strokes per minute will decrease.

Up and Down Buttons:

The UP and DOWN Buttons can be operated only when the Selector Switch is turned to SOF-LOC. When it is

desirable to check the position of the work before making a shearing cut, the holddowns can be lowered by depressing the

DOWN Button. U it is necessary to reposition the work, the UP Button is depressed to release the holddowns. The

machine will not make cutting stroke until the Foot Switch is depressed. The Pressure Switch is preset at the factory to

activate the Clutch Air Solenoid when proper clamping pressure is reached and there should be no need for readjustment

of this setting.

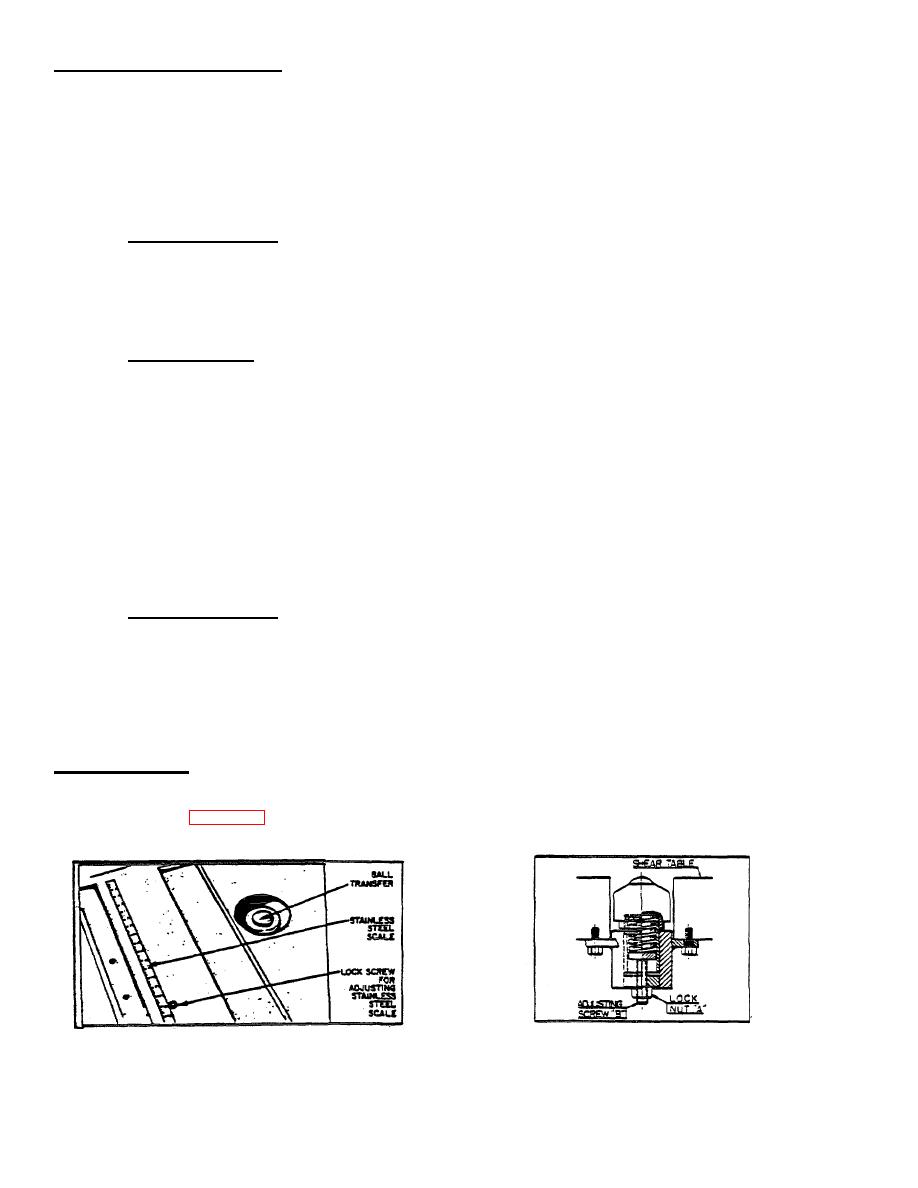

BALL TRANSFERS

Ball transfers (Figure 34) are furnished as standard equipment on the 0800 and 1000 series shears and can be

provided as an optional, extra cost accessory on all other areas.

Figure 34. Ball Transfer

Figure 35. Ball Transfer Adjustment

32