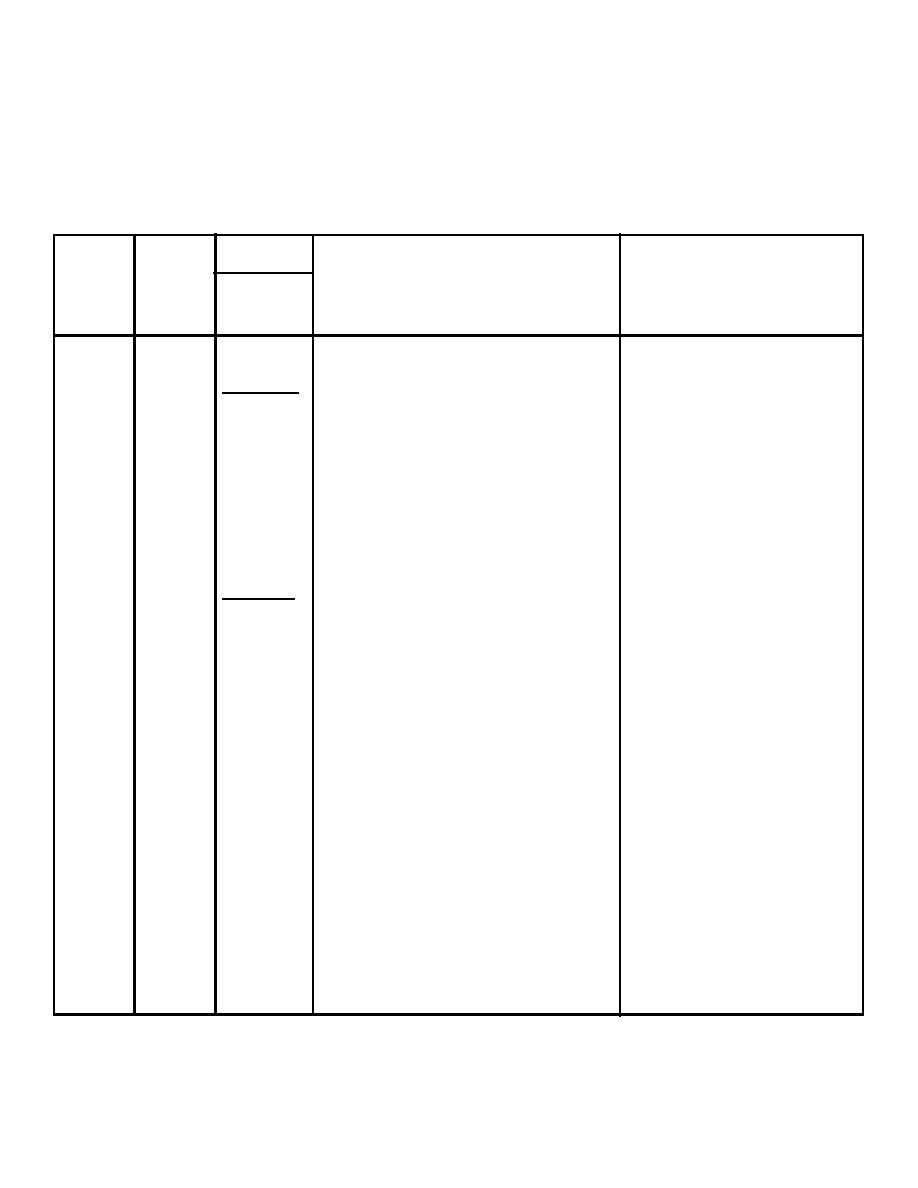

TM 9-4110-255-14

Table 2-1. Operator Preventive Maintenance Checks and Services for Model F5000RD

NOTE

If the equipment must be kept in continuous operation, do only the procedures that can be done

without disturbing operation. Make complete checks and services when the equipment is shut

down.

Location

Item No.

Interval

Procedure

Not Fully Mission Capable If:

Item to

Check/

Service

Refrigeration

Unit Exterior

1

Before

Temperature

a.

Temperature gage should indicate

Temperature gage does

Gage

refrigerator enclosure temperature. If it

not indicate refrigerator

does not, notify unit maintenance to replace

enclosure temperature.

it.

b.

Inspect the Temperature gage for cracked or

missing lens and loose or missing mounting

hardware. If damaged or loose, notify unit

maintenance to tighten or replace it as

necessary.

Refrigeration

Unit Interior

WARNING

Exposed rotating parts are contained in

the refrigeration unit. Care must be

taken when doors are open to prevent

personal injury.

2

Before

Sight

a.

Inspect sight indicator port for cracks and

Sight indicator port is

Indicator

note center indicator color. If cracked or

cracked or center

yellow, notify direct support maintenance to

indicator color is yellow.

replace it or evacuate the refrigeration

system as necessary.

b.

Inspect the sight indicator for evidence of

Evidence of leak is

refrigerant leak. If evidence of leaking

found.

found, notify direct support maintenance to

replace it.

3

Before

V-Belts

Inspect the V-belts for frayed edges, cracks,

V-belt is missing, frayed,

glazing, or hard brittle condition. Inspect for

cracked, glazed, or hard

excessive looseness or slippage. If damaged or

and brittle. V-belt is

loose, notify unit maintenance to tighten or

excessively loose or

replace it as necessary.

slipping.

2-10