TM 9-4110-255-14

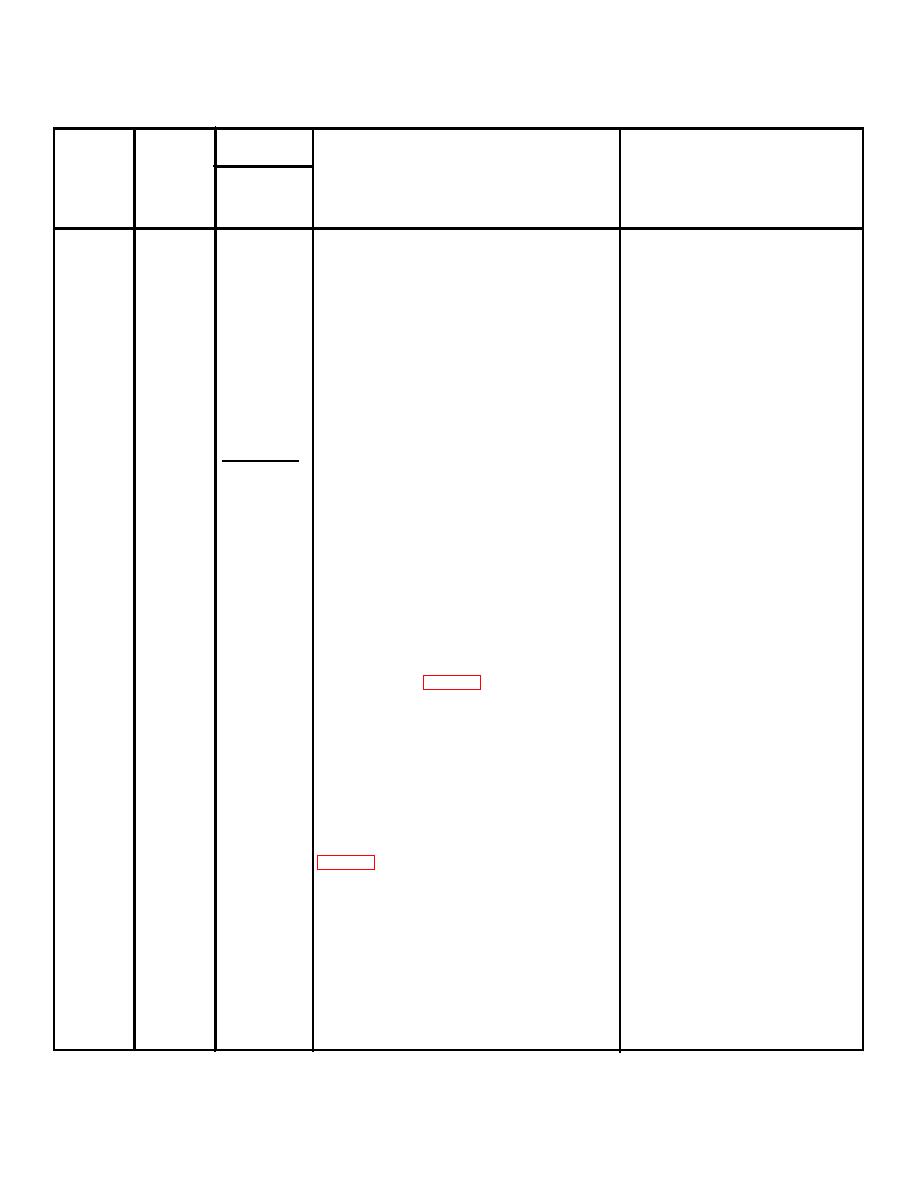

Table 2-1. Operator Preventive Maintenance Checks and Services for Model F5000RD - Continued

Location

Item No.

Interval

Procedure

Not Fully Mission Capable If:

Item to

Check/

Service

9

Before

Fuel Lines

Inspect fuel lines (hoses) for cuts, cracks, and any

If fuel lines (hoses) are

leaking.

cut, cracked, leak is

found.

10

Before

Fuel Pump

Inspect fuel pump for any cracks or leaks.

Fuel pump cracked or

leak found.

11

Before

Fuel Filters

Inspect fuel filters for any dents, cuts, or leaks.

Fuel filter is dented, cut,

or leak is found.

12

Before

Oil Filter

Inspect oil filter for any dents, cuts, or leaks.

Oil filter is dented, cut,

or leak is found.

Refrigeration

Unit Exterior

NOTE

The gages must not be inspected when

the DEFROST IN PROGRESS lamp is

on.

Pressures given are the acceptable

operating range.

13

During

Pressure and Inspect the pressure gage for reading between

Gage reading above or

Compound

160 and 270 psi (1104 and 1863 kPa) and the

below acceptable

Gages

compound gage for reading between 0 and 15 psi

operating range.

(0 and 104 kPa). If either gage is out of

acceptable operating range on a continuous basis,

note the readings and shut down the

refrigeration unit (para 2-7). Notify unit

maintenance of the pressure readings.

NOTE

The temperature gage must not be

inspected when the DEFROST IN

PROGRESS lamp is on.

14

During

Temperature

Temperature gage should indicate within 15F

Temperature gage

Gage

(8C ) of remote bulb thermostat setting. If out

indicates more than

of this range, shut down refrigeration unit

15F (8C) above or

below remote bulb

thermostat setting.

2-12