TM 9-4110-255-14

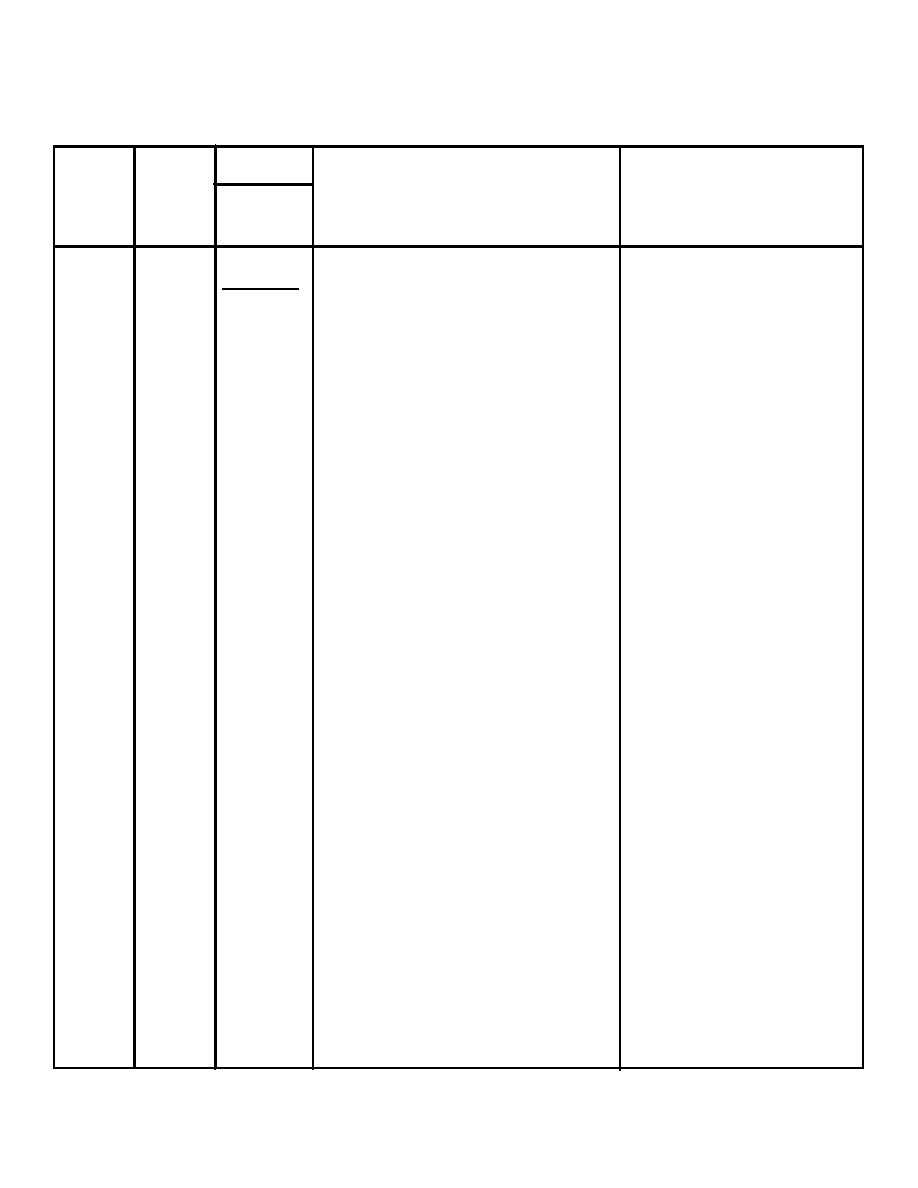

Table 2-1. Operator Preventive Maintenance Checks and Services for Model F5000RD - Continued

Location

Item No.

Interval

Procedure

Not Fully Mission Capable If:

Item to

Check/

Service

Refrigeration

Unit Exterior

22

Weekly

Pressure and a.

Inspect the gages for cracked or missing lens

Compound

and loose or missing mounting hardware. If

Gages

damaged or loose, notify direct support

maintenance to tighten or replace it as

necessary.

b. Inspect the gages for evidence of refrigerant

Evidence of leak is

leak. If damaged or evidence of leaking

found.

found, notify direct support maintenance to

replace it.

23

Weekly

Guards

a. Inspect the guards for any debris or foreign

Debris or foreign

material obstructing the openings. Remove

material obstructs the

any debris or foreign material from the

openings.

openings. If debris cannot be removed,

notify unit maintenance to remove it.

b. Inspect the guards for any cracks, tears, and

loose or missing hardware. If cracked,

notify direct support maintenance for repair.

If hardware is loose or missing, notify unit

maintenance to tighten or replace as

necessary.

c. Inspect for chipped or missing paint and

evidence of corrosion. If paint is damaged

or shows evidence of corrosion, notify direct

support maintenance to paint it.

24

Weekly

Panels

a. Inspect the access panels for any cracks,

tears, and loose or missing hardware. If

cracked, notify direct support maintenance

for repair. If hardware is loose or missing,

notify unit maintenance to tighten or replace

it as necessary.

b. Inspect for any chipped or missing paint

and evidence of corrosion. If paint is

damaged or access panel shows evidence of

corrosion, notify direct support maintenance

to paint it.

25

Weekly

Heat Shield

Inspect for loose or missing heat shield gasket

Gaskets

and for splits or tears. If damaged or loose,

notify unit maintenance to tighten or replace it as

necessary.

2-15