TM 9-4120-378-14

5.21 PRESSURE SWITCHES.- continued

Remarks

Action

L

Location/Item

Check for discontinuity across terminals.

Test (Electrical)

e.

Continued

f. If continuity does not exist, replace defective

switch.

g. Using nitrogen, pressurize high pressure cutout

switch (470-490 psig range/16.3-17.0 kg/cm2

range).

h. Check for discontinuity across terminals.

If continuity does not exist, replace defective pres-

i.

sure switch.

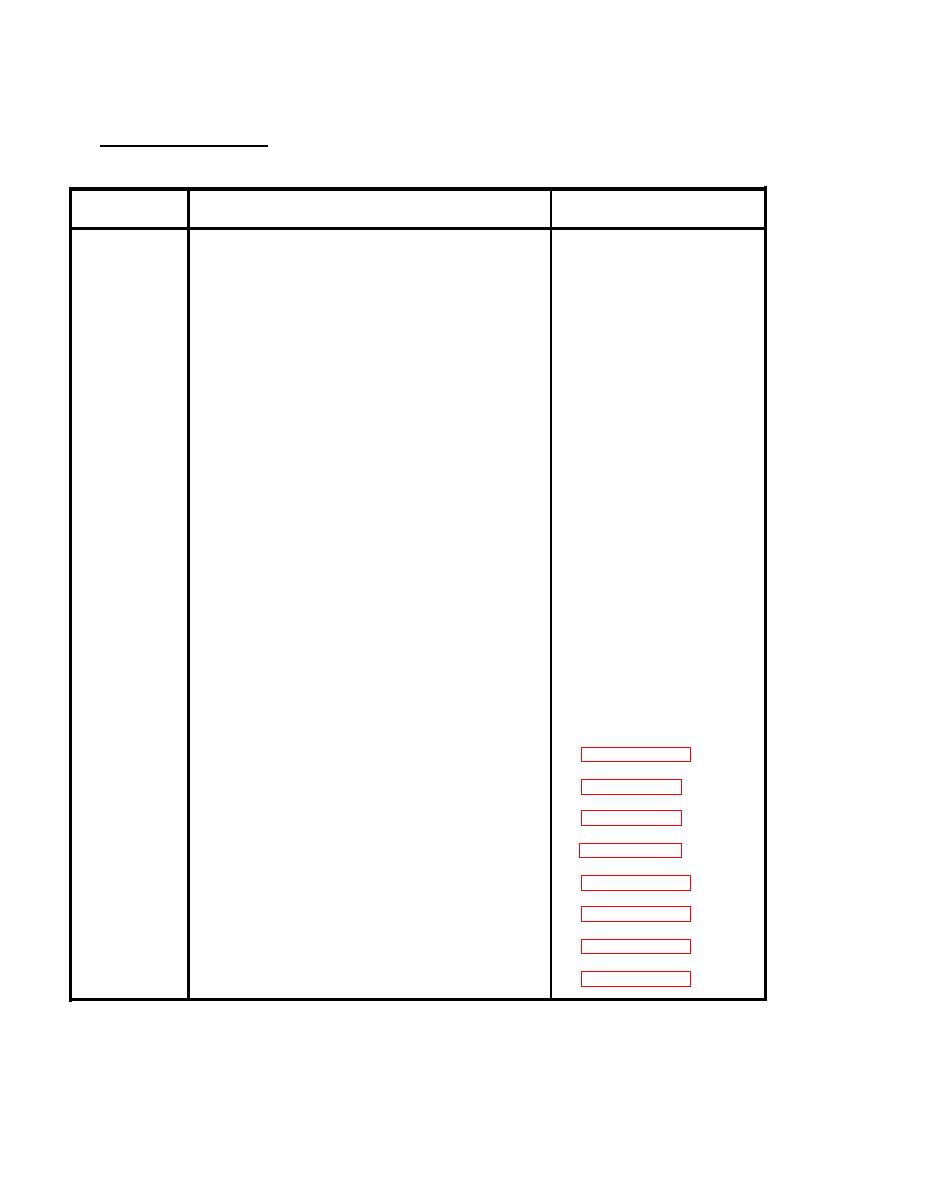

a. Insert ends of capillary tubes through hole in parti-

Installation

tion, being careful to avoid kinking tubes.

b. Install grommet (7) in the partition by sliding it over

both capillary tubes.

c. Connect capillary tube flare nuts (8) to fittings.

d. Install switches (3 and 6) and secure with two

screws (1 and 4) and two Iockwashers (2 and 5).

Keep excess capillary tubing coiled neatly without

kinks.

e. Connect electrical leads and remove tags.

f. Install mist eliminator bracket.

See paragraph 5.25.

g. Replace dehydrator.

See paragraph 5.7.

h. Leak test refrigerant system.

See paragraph 5.8.

Evacuate refrigerant system.

i.

See paragraph 5.9.

Charge system.

j.

See paragraph 4.25.

k. Install junction box.

See paragraph 4.20.

l. Install mist eliminator.

See paragraph 4.18.

m. Install evaporator inlet louver.

See paragraph 4.17.

n. Install top covers.

5-66