TM 9-4120-395-14&P

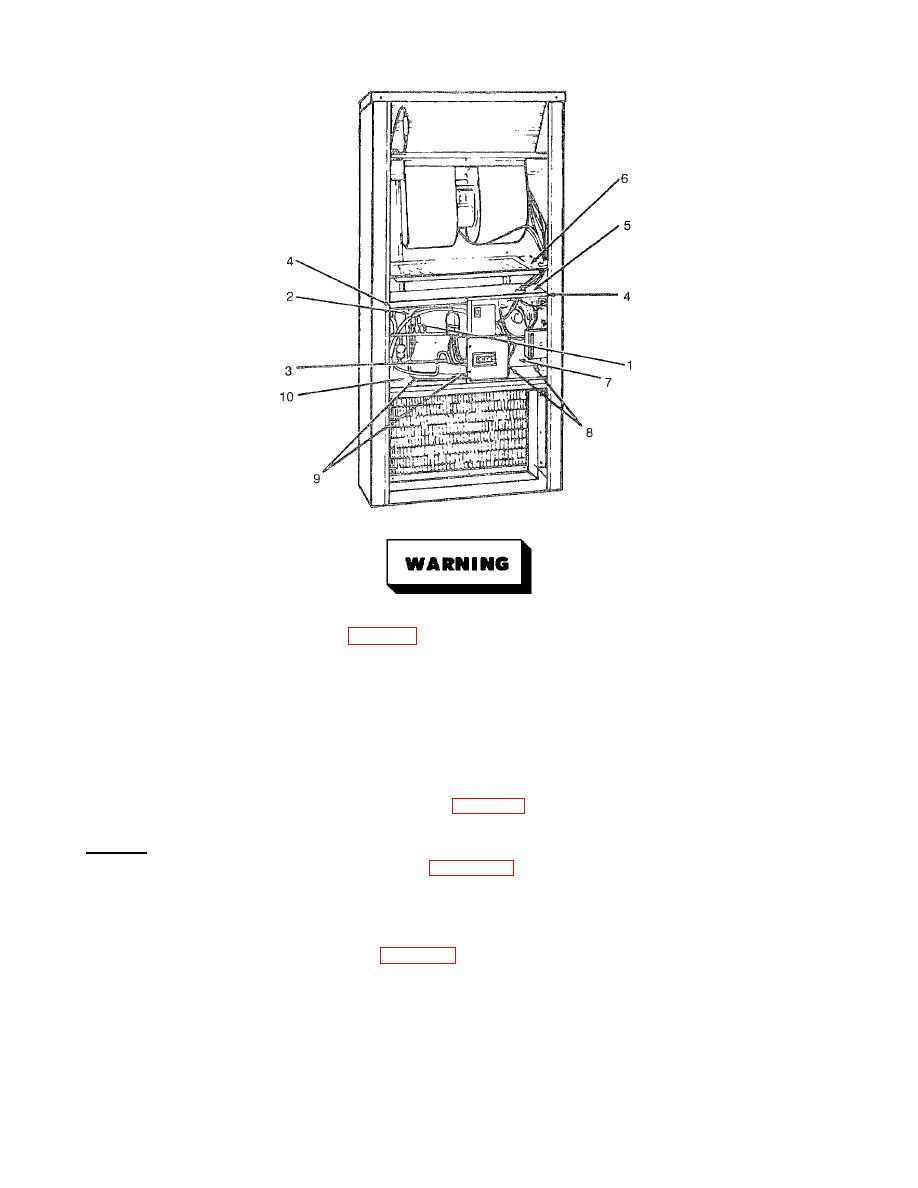

Figure 5-10. Compressor

Avoid getting the refrigerant in the eyes or on the skin.

(6) Discharge the system charge. See para 5-5.

(7) Replace the compressor and correct the system fault that caused the burnout.

NOTE

If the discharge line shows no evidence of sludge and the suction stub is also clean, or perhaps has

some light carbon deposits,

the burnout occurred while the compressor was not rotating.

Contaminants should be largely confined to the compressor housing and a single installation of liquid

and suction line driers will probably suffice to clean up the system. If the sludge is found In the

discharge line (and also found in the suction line) the compressor motor burned out while running

Sludge and acid have been pumped throughout the system and several changes of the driers will

probably be necessary to cleanse the system See para 5-12. Systems suffering running burnouts will

also need the reversing valve replaced. See para 5-19.

b.

Removal.

(1) Unwrap the insulation from the suction line (2, Figure 5-10) so that the joint on the compressor (3) is exposed.

(2) Tag and remove wiring (1) at the compressor (3).

(3) Remove the two screws (4) holding the dividing wall (5).

(4) Lift out filter brackets (6) and lift dividing wall (5).

(5) Remove the control box (7) cover. See para 4-23.

5-37