trichloroethane with the skin or

45. Preventive Maintenance by Operator

prolonged breathing of the fumes

a. Purpose. To assure maximum oper-

is dangerous. Make sure adequate

ational readiness, it is necessary that the

ventilation is provided.

equipment be systematically inspected at

(3) Rubber parts other than electrical.

intervals every day it is operated, so de-

Clean rubber parts with soap and

fects may be discovered and corrected

warm water and dry thoroughly.

before they result in serious damage or

failure. Certain scheduled maintenance

b. General Precautions in Cleaning.

=

services will be performed at these des-

(1) Provide adequate ventilation both

ignated intervals. Any deficiencies dis-

during and after use of trichloroe-

covered that cannot be corrected by the

thane. Work rooms must not be

operator, or corrected by replacing parts

closed in. Avoid prolonged inhala-

will be reported on DA Form 2404.

tion of vapor; headache or nausea

may result. In contact with skin,

b. Daily Preventive-Maintenance Serv-

ice. Each equipment will be inspected each

this cleaner may cause irrita-

day that it is operated. This service is

tion.

divided into three parts, as indicated in

(2) Self-emulsifying decreasing sol-

(1) through (3) below.

vent compound, mineral spirits

(1) Before-operation service. This is

p a i n t thinner, and dry-cleaning

a brief service to ascertain that

solvent are flammable and should

the equipment is ready for opera-

not be used near an open flame.

tion; it is mainly a check to see if

Fire extinguishers should be pro-

c o n d i t i o ns affecting the equip-

vided when se materials are

ment's readiness have changed

used. Use only in well-ventilated

since the last after-operation serv-

places. These cleaners evaporate

ice.

quickly and have a drying effect on

(2) During-operation

This

service.

the skin. If used without gloves,

service consists of detecting un-

they may cause cracks in the skin

satisfactory performance.

and, in the case of some individ-

(3) After-operation service. This is

uals, a mild irritation or inflam-

the basic daily service for the

mation.

equipment. It consists of correct-

(3) Avoid getting petroleum products,

ing, insofar as possible, any op-

such as mineral spirits paint thin-

erating deficiencies. Thus, the

ner, dry-cleaning solvent, engine

equipment is prepared to operate

fuels, or lubricants, on rubber

upon a moment's notice.

parts, as they will deteriorate the

rubber.

(4) The use of Diesel fuel oil, gaso-

46. Specific Procedures for First Echelon

line, or benzene (benzol) for clean-

Table I gives the specific procedures to

ing is prohibited.

be performed on the equipment by the op-

erator for each daily service.

c. Rust Removal. Remove rust or cor-

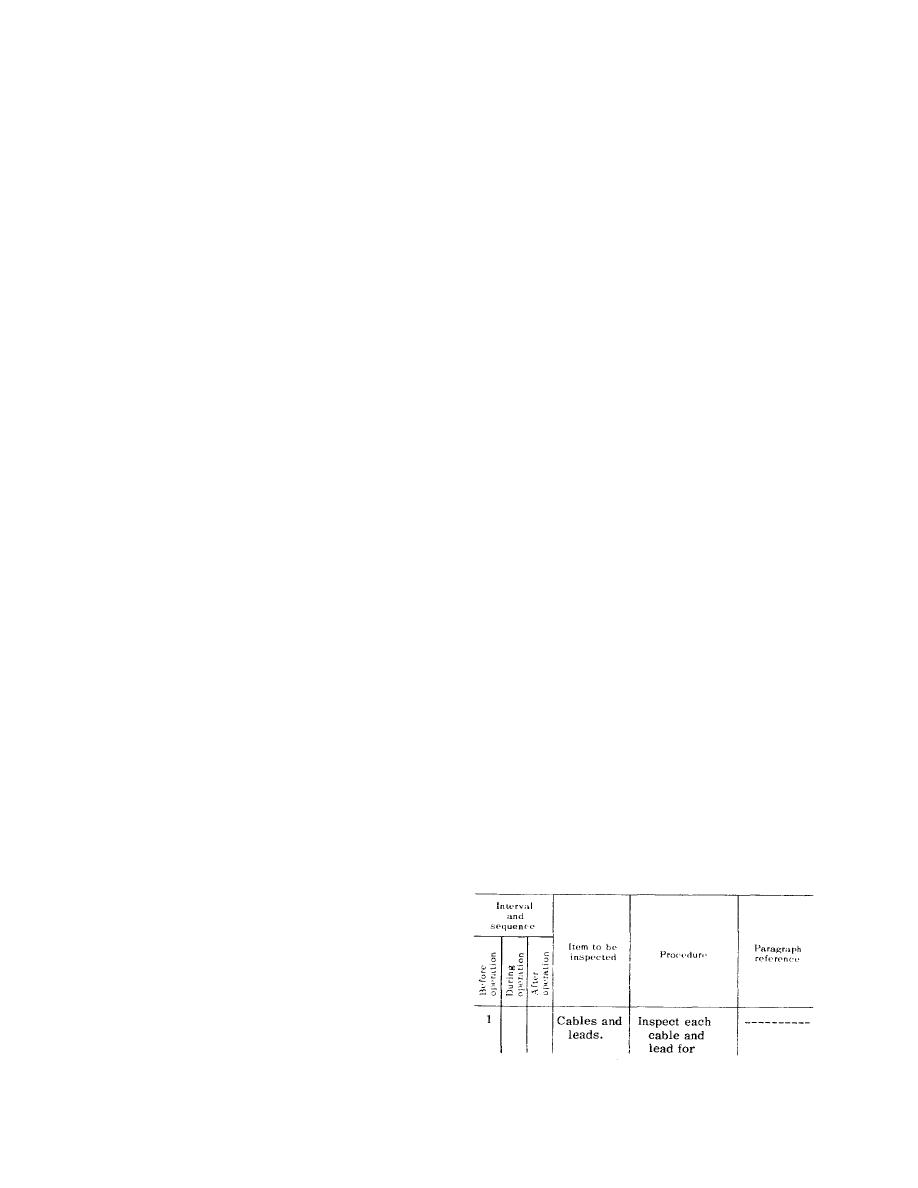

Table I. Preventive-Maintenance

rosion from all parts of the materiel. To

Checks and Services

remove rust or corrosion from unfinished

1st Echelon

Daily Schedule

surfaces, use steel cleaning brushes or

abrasive cloth. On finished surfaces, other

than highly polished surfaces, remove rust

or corrosion by buffing with a rotary wheel

wire brush constructed of steel wire be-

tween 0.010 and 0.025 inch in diameter.

Crocus cloth may be used manually to re-

move rust or corrosion from polished

surfaces.

20