TM 55-4920-384-13&P

the full load and no load speeds of the engine and the

hole corresponding thereto. The full load speed will

a clockwise direction one notch at a time until a very

be from 150 to 125 revolutions less than the no load

firm pressure is required to engage the clutch by the

speed. As an example, if the engine is to be operated

operating lever. Take-off shaft must be kept from

at 2000 revolutions per minute under load, the spring

turning when making this adjustment. Be sure to re-

should be hooked into the 8th hole in the governor

engage the adjusting ring lock into a notch in the

ring. Replace inspection cover.

lever and the spring tension adjusted by means of the

adjusting screw connected to the spring, to run 2125

For the Twin Disc clutch, pull adjusting lockpin out,

revolutions per minute, without load. The speed at

as shown in Fig. 38, and turn the adjusting yoke in a

full load will then be approximately 2000 revolutions

clockwise direction until the operating lever requires

per minute. A tachometer or revolution counter should

a distinct pressure to engage.

be used against the crankshaft while adjusting the

governor spring tension to give the proper engine

speed.

CLUTCH REDUCTION GEARS

CLUTCH AND REDUCTION UNITS

Clutch reduction gears are furnished with several

CLUTCH POWER TAKE-OFF

different ratios, some with spur gears, for counter-

enginewise rotation, others with internal gears, for

The clutch furnished with this model of engine is of

enginewise rotation. The clutch is of the dry disc

the dry disc type. No oil should be put into the clutch

type and no oil should be put into the clutch housing.

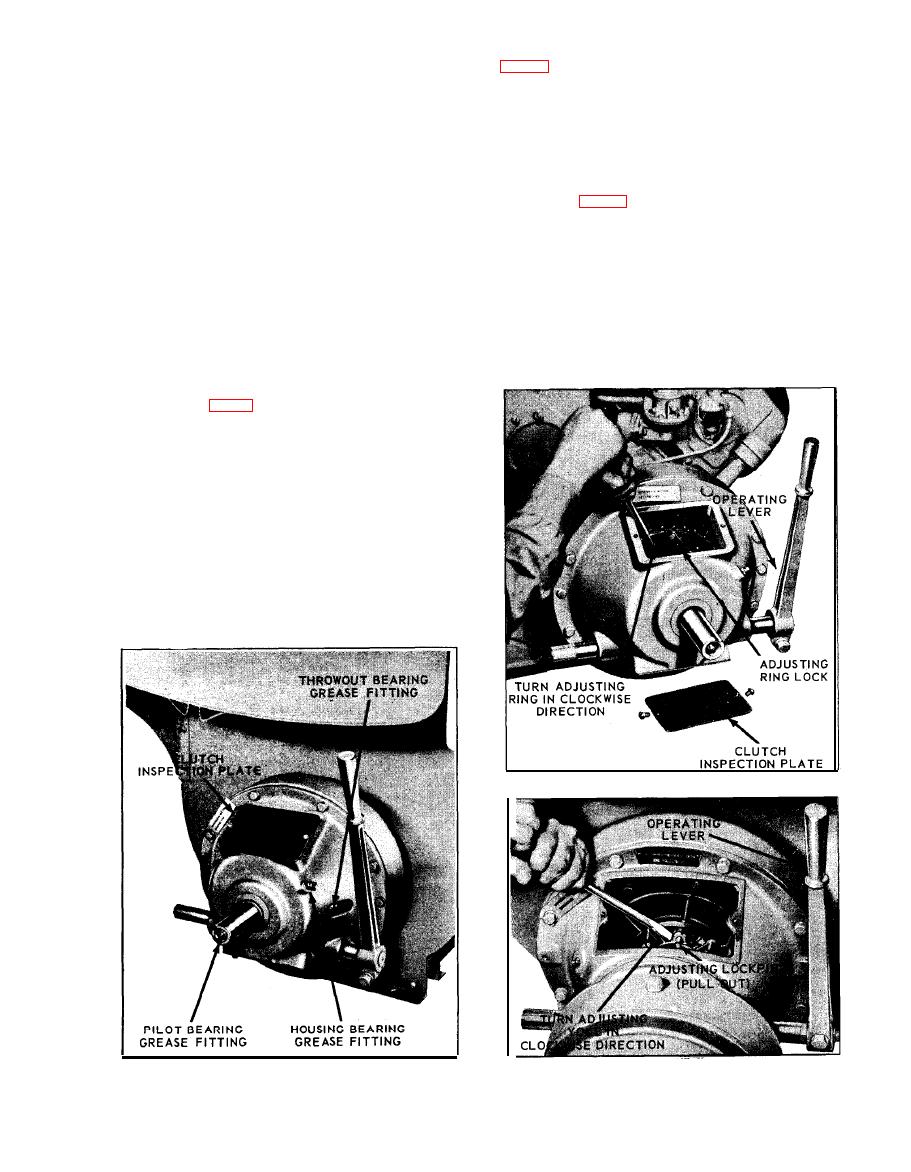

housing. There are three points on these clutches re-

quiring lubrication and these are filled with grease at

the factory, see Fig. 36. Grease gun fittings are fur-

nished for periodic lubrication. The housing bearing

and pilot bearing should receive additional grease

every fifty hours of operation. The clutch t h r o w o u t

bearing should be greased every day before starting.

Use Mobil Gargoyle grease BRB No. 3, Sinclair AF-1

grease, or equal.

CLUTCH ADJUSTMENT

If the clutch begins to slip, it should be readjusted,

otherwise it would become overheated and damaged.

F i r s t release clutch operating lever and remove

clutch inspection plate. For the Rockford clutch, turn

clutch over until adjusting ring lock is up. Release

lock with a screw driver or similar tool as shown in

104574C

104578C

104570C

D-23