TM 55-4920-384-13&P

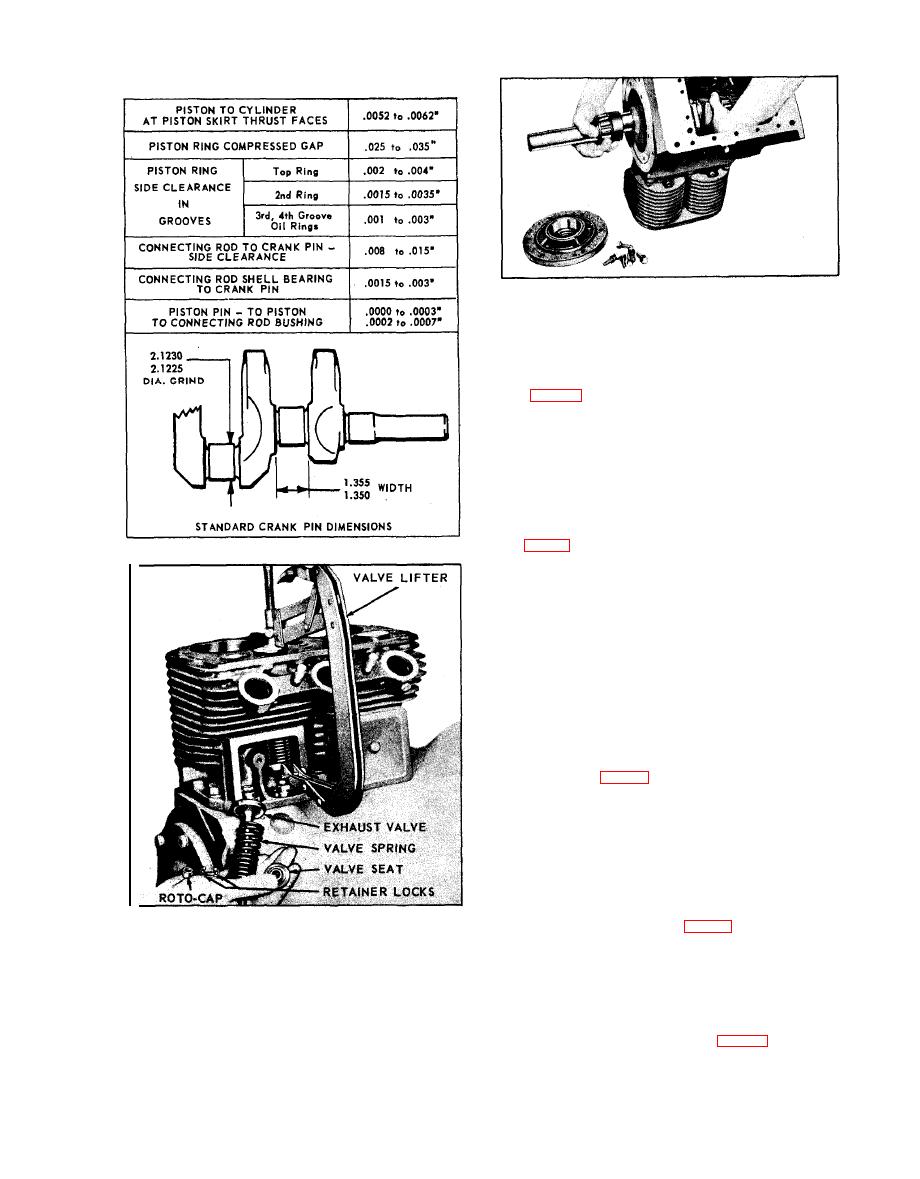

PISTON, RING AND ROD CLEARANCES CHART

71075C

CRANKSHAFT

To remove the crankshaft, first remove the six cap-

screws in the main bearing plate at the take-off end

of the engine. The plate can then be pried off and

the crankshaft removed from that end of crankcase.

place as these are necessary to give the proper end

play to the tapered roller bearings on the crankshaft.

This end play should be .002 to .004 inch when en-

gine is cold. There is practically no wear in these

bearings so that no readjustment is necessary after

proper assembly.

When reassembling crankshaft, the timing marks on

the crankshaft gear and camshaft gear must match up,

perly, or if timing is off considerably, engine will

not run at all.

Mount main bearing plate in the correct position in

reassembly. The word `TOP' is cast on the outside

of the plate, and should be mounted in this position.

Mounting the main bearing plate upside down would

prevent the main bearing from being properly lubricat-

ed. Tighten main bearing plate capscrews, 25 to 30

foot pounds torque.

CAMSHAFT

Remove all valve tappets and withdraw camshaft from

crankcase. See Fig. 33. When replacing, be sure the

spring and plunger are in place in the end of the cam-

shaft, as these hold the camshaft in position endwise.

Camshaft gear is removed by taking out the three

screws and lockwashers, and then prying the gear off

t h e end of the camshaft. The camgear has offset

m o u n t i n g holes to provide accurate assembly for

valve timing. The gear can only be put on the correct

way for matching up the timing mark with that of the

189221 C

crankshaft. See Gear Train, Fig. 22.

The cylinder blocks have replaceable valve guides.

VALVE TAPPETS - ADJUSTMENT

The valve stems have a clearance of .0025" to .0045"

in the guides. When the clearance becomes .008",

The valve tappets must be pulled out before the

the guides should be driven out and replaced with

camshaft is removed. In reassembly, the tappets can

new guides.

be inserted in proper position in the crankcase after

the camshaft is reassembled. See Fig. 33.

The valves and valve seat inserts are of 'Stellite'

After the cylinder block assemblies have been mount-

material.

ed to the crankcase, the tappets should be adjusted.

D-21