TM 55-4920-384-13&P

209574C

Use a suitable ring compressor in reassembly and

stagger the piston ring gaps 90 apart around the

and cylinder walls before assembly.

CYLINDERS

The cylinder blocks can now be removed from the

c r a n k c a s e if necessary. In reassembling, put the

blocks back on the same side from which they were

removed. Clean all dirt and other deposits from fins

104819C-1

before reassembling. If the cylinders are worn more

than .005 inch oversize, they should be reground and

fitted with oversize pistons and rings.

Tighten cylinder block mounting nuts, 62 to 78 foot

pounds torque.

VALVES

Remove the valve tappet inspection plate and com-

press the valve springs with a standard automotive

type valve lifter, as shown in Fig. 31. If cylinder

block is still attached to the engine, insert a rag in

the opening at the bottom of the valve chamber so the

roto-cap and valve spring seat retaining locks do not

fall into the crankcase. Remove the roto-caps, valve

s p r i n g seat retaining locks, seats, springs, . .valves

and clean these, as well as the ports and guides, of

71152C

all carbon and gum deposits. Tag each valve so that

in reassembly they will be mounted in the same guide

the engine, be sure the arrow on the top of the piston

they were removed from.

is pointing in the direction of crankshaft rotation.

(Clockwise when viewing the flywheel end of the en-

Non-positive type roto-caps are provided on the ends

gine). See Engine Sectional, Fig. 3.

of the valve stems. In reassembly, be sure to assem-

ble the roto-caps to the end of the valve stems.

Tighten connecting rod nuts, 28 to 32 foot pounds

torque, then install `Pal' locknuts and tighten with

The valve face is ground at 45 to the vertical cen-

wrench 1/4 turn beyond `finger-tight' position.

ter line of the valve stem and the valve seat insert

should also be ground at a 45 angle. After grinding

Be sure piston and connecting rod assemblies are

valves and inserts should be lapped with a suitable

put back into the same bore from which they were

lapping compound or they will leak due to improper

removed.

seating within the first few hours of operation. After

PISTON RINGS

valve seats have been cleaned, apply lapping com-

pound to the valve face and put the valves back into

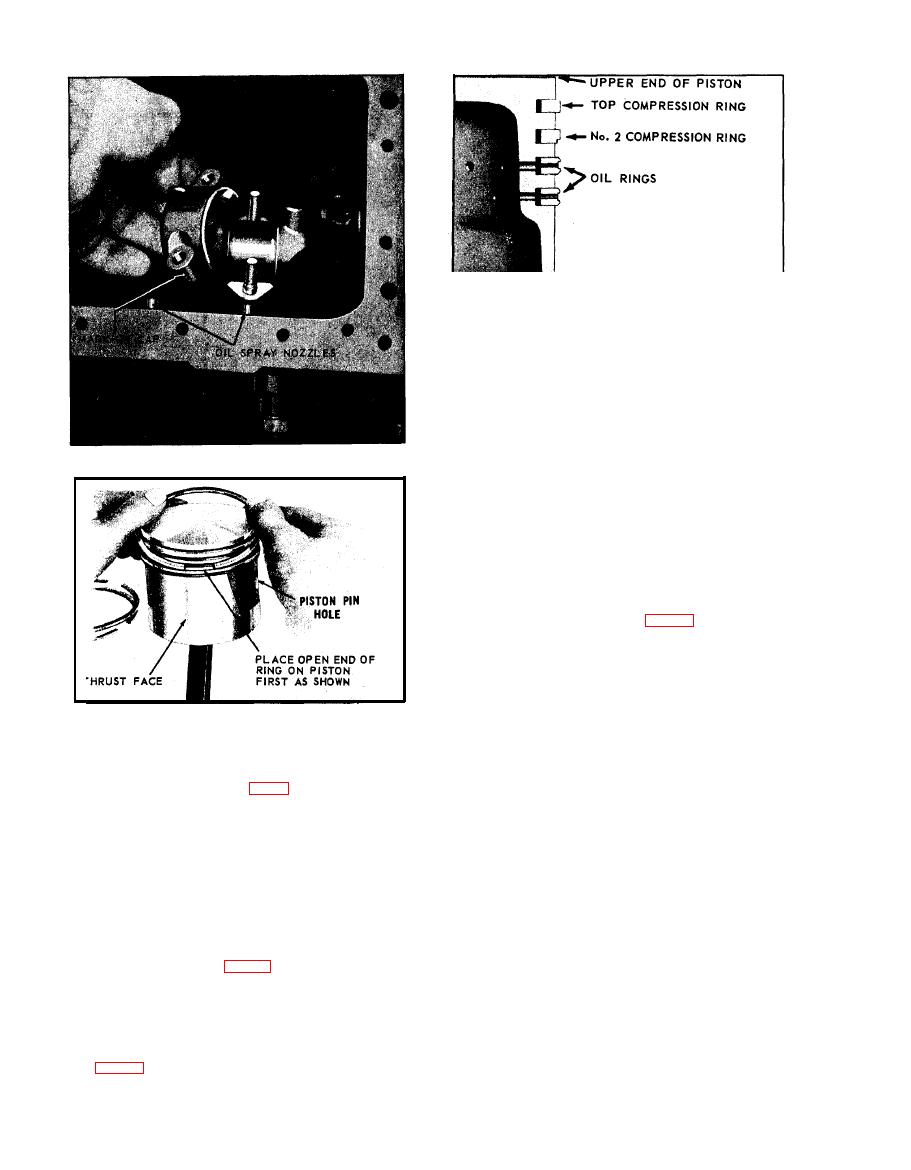

Install rings by placing the open end of the ring on

their guides. Lap the valves by rotating them back

piston first, as shown in Fig. 28. Spread ring only far

and forth with a reciprocating advancing valve tool.

enough to slip over piston and into correct groove,

O c c a s i o n a l lift the valves and reseat them in a

being careful not to distort ring.

different position to insure a uniform seat which will

The Number 2 compression ring must be installed on

show entirely around the valves. After valves have

the piston with the scraper edge down, otherwise oil

been lapped in evenly, remove them from the block

pumping and excessive oil consumption will result,

and wash the valves and block thoroughly with gaso-

See Fig. 29.

line or kerosene.

D-20