TM 9-1345-203-12

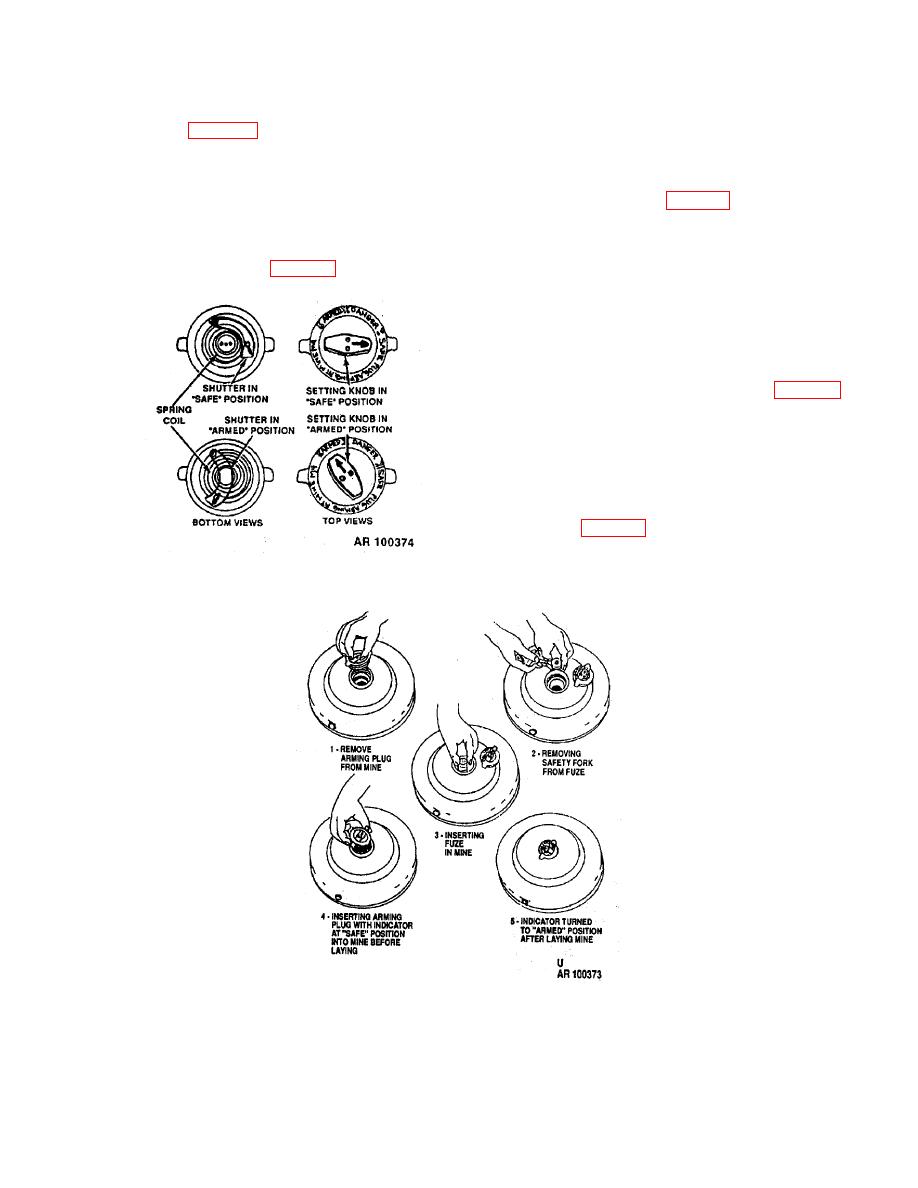

(11) Check clearance of pressure plate of fuze

in fuze well by using tab end of wrench

(13) For long-term emplacement, smear layer

M20 (fig. 2-20). If pressure plate is too

of silicone grease G-697 on threads,

high, the bottom of the plate will interfere

gasket, and shutter on underside of the

with the movement of the arming shutter

arming plug.

in arming the mine. If fuze does not fully

(14) Screw arming plug clockwise into fuze

seat, remove and replace with another

well of mine (fig. 2-26).

fuze.

(15) Tighten arming plug with wrench M20 to

(12) Pick up arming plug M4 and turn setting

assure watertight joint.

knob to SAFE position (if not already set

(16) For long-term emplacement:

to SAFE position) (fig. 2-25).

(a) Coat outside of arming plug 360

with grease G-697.

(b) Smear film of grease 360 on joint

where mine pressure plate is

attached to mine body.

(17) Dig hole approximately 15 inches in

diameter and 6 inches deep, with walls

sloping 45to avoid bridging (fig. 2-26).

(18) Check bottom of hole to assure ground is

solid and mine will not sink in ground. If

not solid, insert wood board or other

surface to give mine firm foundation.

(19) Lay mine in hole so that top surface of

pressure plate is approximately 1 1/2

inches below the surface of the ground

positions.