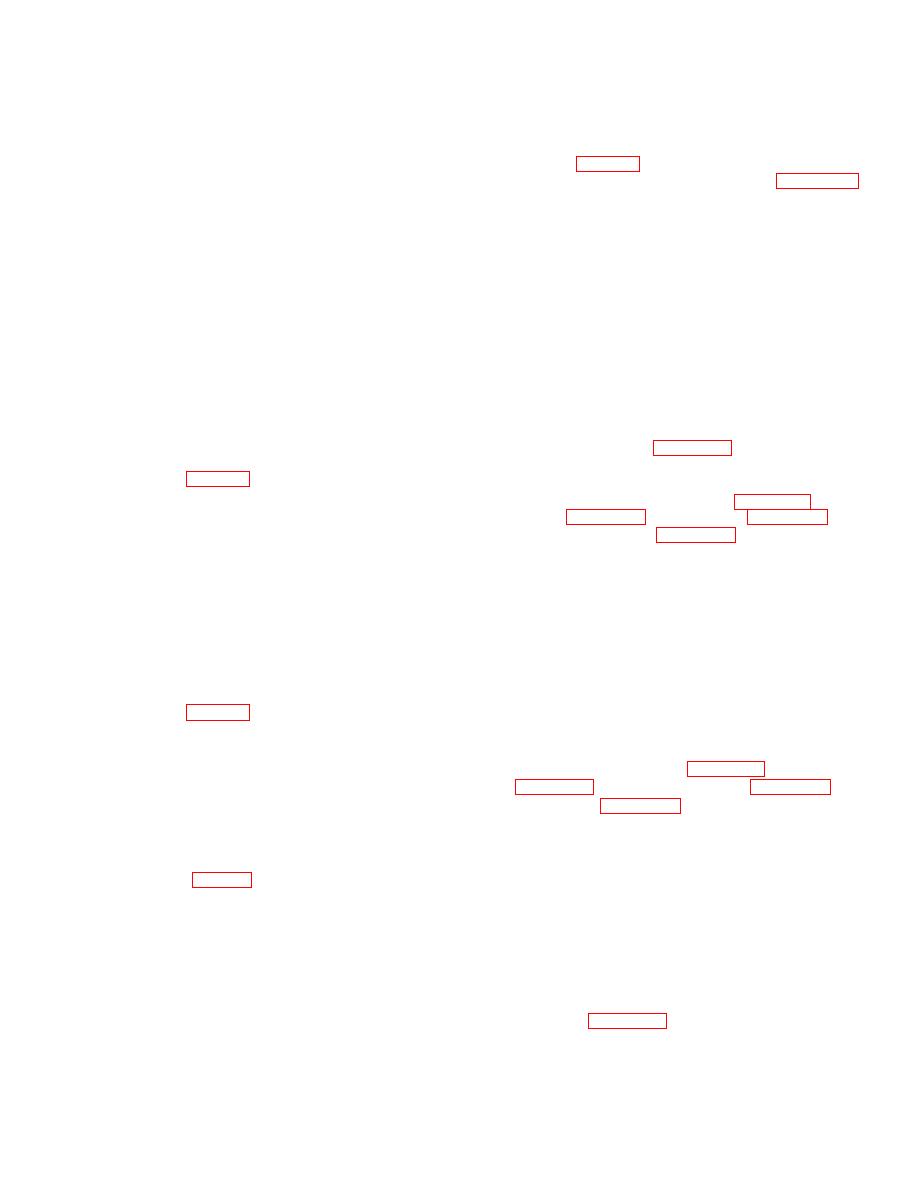

the leg is toward the rear of the trailer. Assemble

ALunette

BSafety chain capscrew

the two capscrews and castle nuts. Tighten the nuts

CSupport leg bracket pivot screw

so that the cotter pin holes line up with one slot of

DLunette

support

bracket

the nuts. Insert the cotter pins and bend them over.

EClip

4-24. Support Leg Bracket

FLockwasher

GCapscrew

H L u b r i c a t i o n fitting

JSpring washer

Remove the cotter pin and castle nut from the

KLunette spring

support leg bracket pivot screw in the front support

L-Keyed washer

bracket. Withdraw the screw. Pull out the support

MCotter pin

leg plunger and slide the support leg bracket out of

N L u n e t t e castle nut

P A - f r a m e channel

the lunette support bracket.

QCotter pin

b. Installation. Pull out the support leg plunger

RCastle nut

and slip the support leg bracket up into place in the

S S u p p o r t leg bracket

lunette support bracket so that the pivot screw

TCotter pin

holes in both brackets are in line. Insert the pivot

UCastle nut

V S u p p o r t leg

screw and assemble the castle nut and tighten it so

W S u p p o r t leg capscrew

that the cotter pin hole in the screw lines up with

X S a f e t y chain

one slot of the nut. Do not tighten to the point

YCotter pin

where support leg movement is hampered. Insert

ZCastle nut

A A S u p p o r t leg plunger

the cotter pin and bend it back around the nut.

Install support leg (para 4-23).

4-22. Safety Chains

4-25. Lunette Support Bracket

(fig. 4-l0)

a. Removal. Remove the cotter pin and castle nut

chains (para 4-22), support leg (para 4-23), and

from the safety chain capscrew. Remove the cap-

screw from the lunette support bracket.

support leg bracket (para 4-24). Remove the four

b. Installation. Place the safety chain fasteners

cotter pins and castle nuts from the bracket cap-

against the frame, one on each side, flat side out, so

screws. Remove the screws and slide the lunette

that the screw holes are in line. Slip the capscrew

support bracket out from between the two channels

through the chain fasteners, the frame, and the

to the rear.

lunette support bracket and assemble the castle

b. Installation. Slip the lunette support bracket

nut. Tighten it so that the cotter pin hole in the

between the A frame channels so that the lunette

screw lines up with one slot of the nut. Insert the

hole is on top. Line up the holes in the bracket with

cotter pin and bend it back around the nut.

those in the A frame channels and insert the four

4-23. Support Leg

capscrews with the heads on the outside of the

channels. Assemble the four castle nuts and tighten,

a. Removal. Remove the two cotter pins and

lining up one slot with the cotter pin hole in the

castle nut located on the rear of the support leg

screw. Insert the cotter pin and bend it back around

bracket. Remove the support leg capscrews.

the nut. Install lunette (para 4-21), safety chains

b. Installation. Position the support leg on the

front of the support leg bracket so that the loop of

support leg (para 4-23).

Section X. WHEELS AND TIRES

operation, 25 psi, for operation in sand, or snow 10

4-26. Wheel and Tire Assembly

psi. Pressure must be equal in both tires.

NOTE

a. Removal. Lossen, but do not remove, the

Take tire pressure readings when tires are

wheel-bolt nuts. Jack up the trailer on the side of

cold; d o not reduce the pressures of

the wheel to be removed. Remove the five nuts and

overinflated hot tires. Allow the tires to

lift off the wheel.

cool, check the pressures, and deflate them

b. Installation. Place the wheel on the drum over

if necessary.

the five wheel bolts and assemble the five nuts

b. Removal. After removing the wheel and tire

finger tight. Lower the vehicle so that the tire

assembly (para 4-26), completely deflate the tube

touches the ground, or apply the parking brake,

by removing the valve core. Use tire irons to

and tighten the nuts.

dislodge the bead of the tire and carefully force it

4-27. Tires

off the rim. Remove the tube and pull the back

a. Inflation. Standard tire inflation pressure for

bead of the tire off the rim.

highway operation is 25 psi, for cross-country

4-13