TM 9-2330-271-14&P

CHAPTER 5

DIRECT SUPPORT AND GENERAL SUPPORT

MAINTENANCE INSTRUCTIONS

Section I. REPAIR PARTS, SPECIAL TOOLS AND EQUIPMENT

5-1. Special Tools and Equipment.

5-2. Repair parts.

Special tools and equipment are listed and illustrated in

Repair parts that cover direct and general support

Appendix E. The oil seal replacer (1, fig. 87) and wheel

maintenance for this equipment are listed and illustrated

bearing adjusting nut wrench (2, fig. 87) are used in

in Appendix E.

maintenance procedures for the hubs and brake drums.

Section II. TROUBLESHOOTING

5-3. Introductory Information.

Step 2.

Check for broken spring leaves, center

bolt, or clips

a. This

section

contains

troubleshooting

Replace spring, bolt or clip as necessary

information for locating and correcting most of the

operating troubles which may develop in the semitrailer.

5.

EXCESSIVELY WORN, SCUFFED, OR CUPPED

Each malfunction for an individual component, unit, or

TIRES

system is followed by a list of tests or inspections which

Step 1.

Check for Improper tire pressure

will help you to determine the corrective actions to take.

Inflate to proper pressu re (paragraph 3-18b)

You should perform the tests/inspections and corrective

Step 2.

Check for loose wheels.

Tighten wheel nuts

actions in the order listed.

Step 3.

Check for loose wheel bearings

b. This manual cannot list all malfunctions that

Adjust wheel bearings (paragraph 4-47f)

may occur, nor all tests or inspections and corrective

Step 4.

Check for deformed wheel or rim

actions. If a malfunction is not listed or is not corrected

Replace defective wheel (paragraph 3-18)

by listed corrective actions, notify your supervisor.

Step 5.

Check for deformed brake drum

Replace deformed brake drum (paragraph

you may find during the operation or maintenance of the

semitrailer or its components. You should perform the

Step 6

Check for bent axle

Replace defective axle

tests/inspections and corrective actions in the order

LANDING GEAR (Rigid Type)

listed.

6.

ERRATIC OPERATION (BINDING AND

GRINDING)

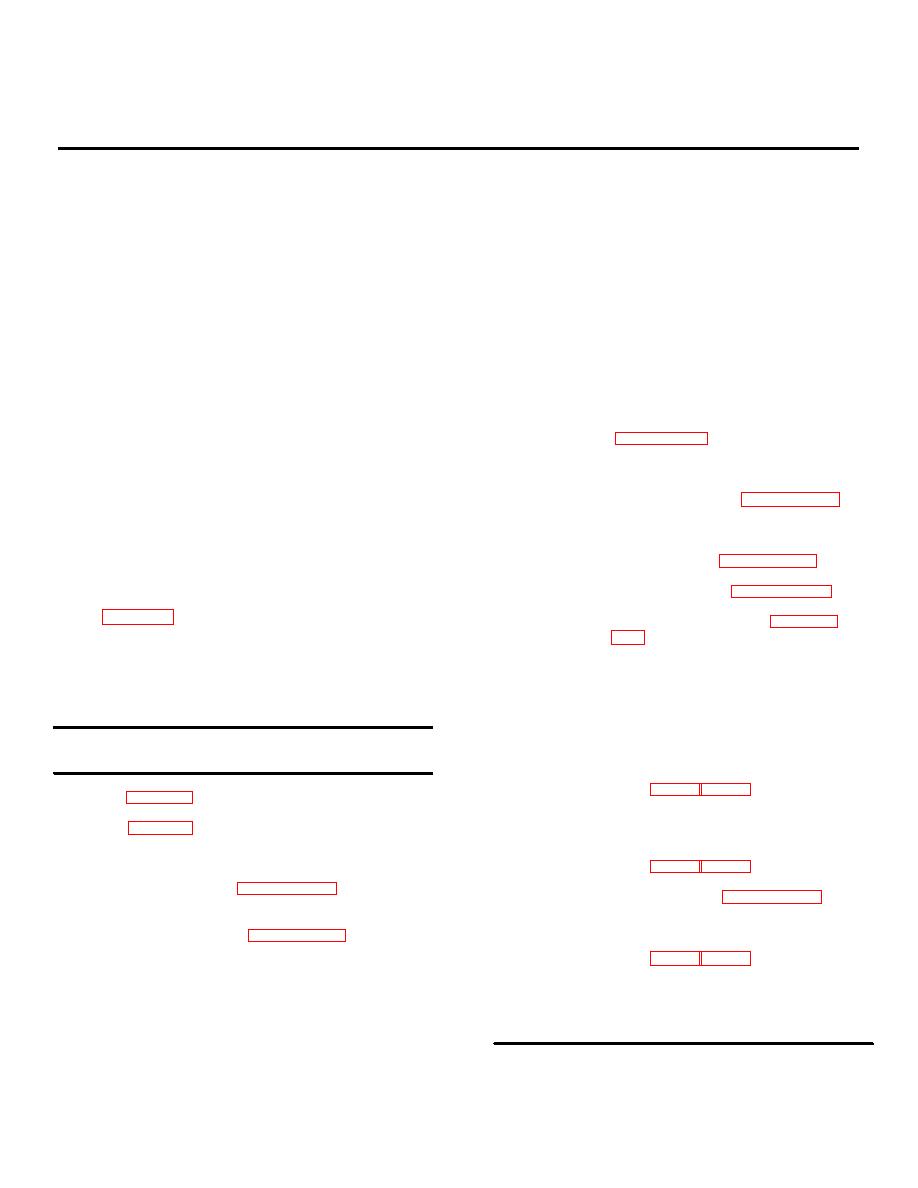

Table 5-1 Troubleshooting

Step 1.

Check for grit and dirt on working parts

MALFUNCTION

Clean working parts

TEST OR INSPECTION

Step 2.

Check for adequate lubrication

CORRECTIVE ACTION

Lubricate in accordance with the lubrication

ELECTRICAL SYSTEM

1.

Refer to table 4-2

7.

RATCHET CRANK DOES NOT TURN LANDING

BRAKE SYSTEM

GEAR SHAFT FREELY

2.

Refer to table 4-2

Step 1.

Check for adequate lubrication

SUSPENSION

Lubricate in accordance with the lubrication

3.

HARD PULLING.

Step 1.

Check for dragging brakes

Step 2.

Check for broken gear in gear train

Adjust brakes (paragraph 4-32)

Replace defective gear (paragraphs 7-3, 7-6)

Step 2.

Check for improper wheel bearing

8.

LEGS DO NOT RETRACT OR EXTEND FREELY

adjustment

Step 1.

Check for adequate lubrication

Adjust bearings (paragraph 4-47f)

Lubricate in accordan ce with the lubrication

Step 3.

Check for loose suspension springs.

Tighten U-bolt nuts

Step 2.

Check for defective gear train in leg.

4.

IMPROPER SPRING ACTION.

Replace defective part of gear train (para-

Step 1.

Check for loose U-bolt

graphs 7-3, 7-6).

Tighten U-bolt nuts

Step 3.

Check for damaged leg

Replace defective leg.

5-1