TM 9-2330-356-14

Hose Reef Hoses. After a hose reel hose is

a.

unreeled from the hose reel for a fuel servicing operation,

visually check the hose for damage. If damage is noticed,

notify unit maintenance.

b.

and the hose reel handcrank operation shafts weekly

(Section I, Chapter 3).

Cleaning. Periodically clean tool box of dirt and

a.

debris. Make sure drain holes are open.

Inspect. Inspect tool box cover and tool box for

b.

damage. Report any damage to unit maintenance.

Drain water from filter/separator after each period of

operation (para 2-13 d).

M970A1)

NOTE

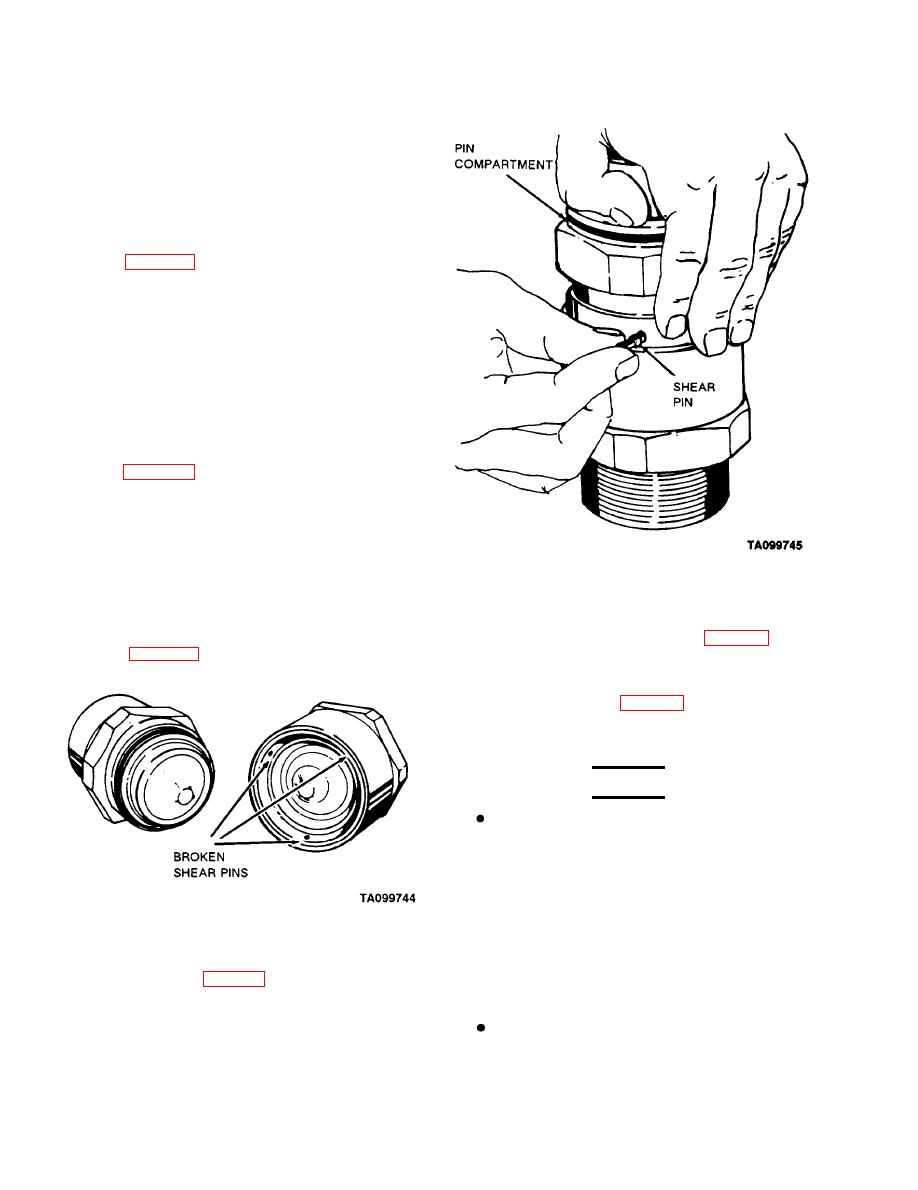

Breakaway Fitting.

Installation of shear pins may be done with-

out removing connector from vehicle.

a. Retract sleeve and remove broken shear pin

be cleaned periodically and whenever flow is restricted

segments (fig. 3-24).

through nozzle.

(1) Unscrew spout (fig. 3-26) from nozzle.

(2) Remove screen from within the spout.

WARNING

Dry cleaning solvent P-D-680 is toxic and

flammable. Always wear protective

goggles and gloves, and use only in a well-

ventilated area. Avoid contact with skin,

eyes, and clothes, and DO NOT breathe va-

pors. DO NOT use near open flame or ex-

cessive heat. The solvent's flash point is

Breakaway Fitting.

100F-138F (38C-59C). If you be-

come dizzy while using cleaning solvent,

b.

Remove three new shear pins from compartment

Immediately get fresh air and medical help.

under external O-ring (fig. 3-25).

If solvent contacts eyes, Immediately wash

your eyes with water and get medical aid.

Retract sleeve, push connector halves together

c.

and hold. Insert pins in three holes until flush (pins must

Compressed air used for drying or clean-

engage race in mating half). Sleeve will then slide forward

ing purposes must not exceed 30 psi

and cover pins.

(207 kPa). Wear protective clothing