TM 9-2330-356-14

(3) Inspect plunger seals and gaskets for damage,

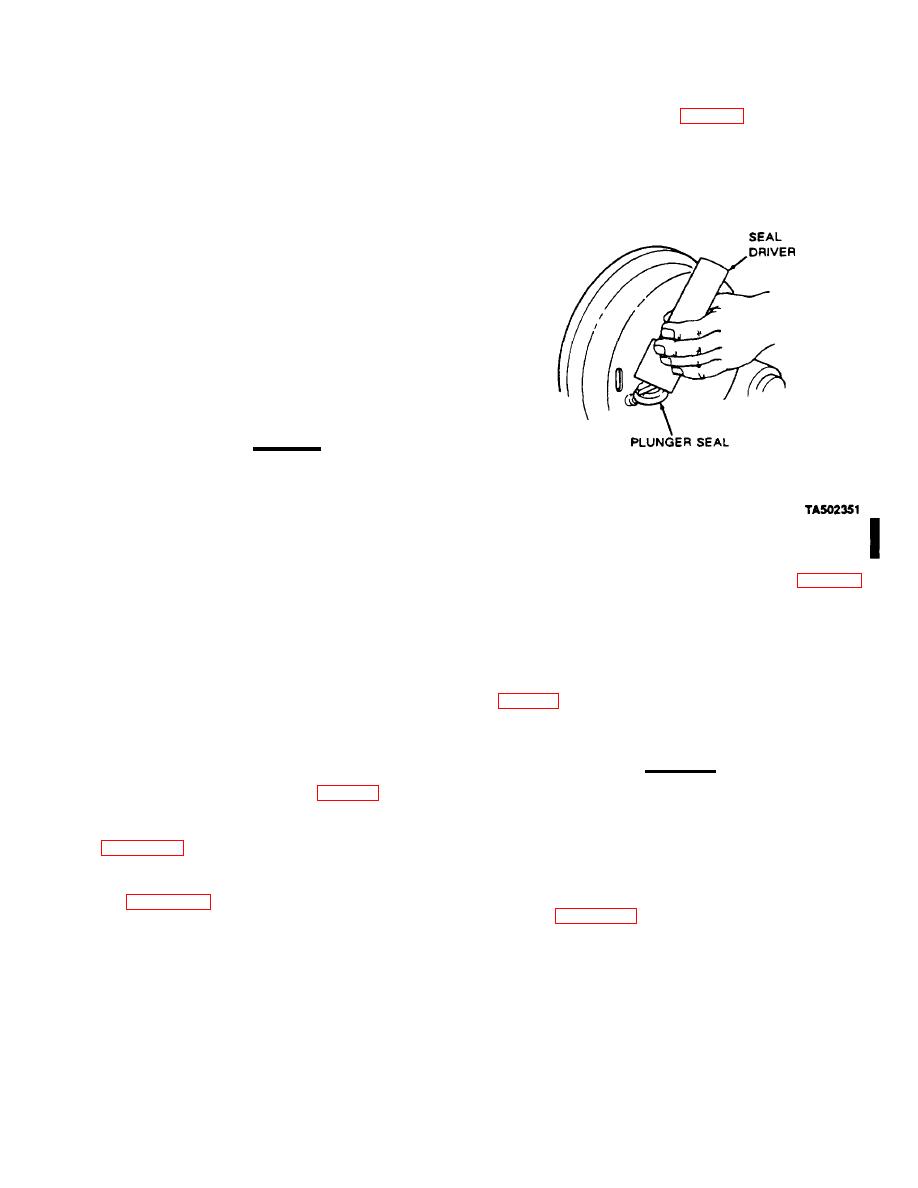

(d) Seat the plunger seal assembly in plung-

cuts, or deterioration.

er housing with seal driver (fig. 4-67). A 1-inch wrench

socket and rawhide mallet can also be used. Ensure that

the seal is centered over the seal retainer to prevent dam-

(4) Inspect plungers for rust, nicks, pits, or

age to seal assembly.

grooves.

(5) Check for burrs on nose of anchor plunger.

Remove burrs with a fine file or crocus cloth. A bright,

shiny surface where wedge roller contacts the plunger

surface is normal.

(6) Check threads of adjusting bolt for damage.

(7) Replace all parts which are not in good

condition.

Installation of Anchor (Solid) Plunger.

e.

CAUTION

DO NOT assemble seals Into plunger housing

first. This will result in complete lack of seal-

ing of Internal plunger housing components.

M969, and M970 except M970 SN TC-0843, TC-0844.

NOTE

and TC-103 thru TC-178).

Each plunger housing assembly has one ad-

(3) Assemble gasket and guide screw (fig. 4-66)

justing plunger and one anchor (solid) plung-

into guide hole in plunger housing. Ensure that the end of

er. The l nchor plunger Is marked on the

guide screw enters keyway slot in plunger so anchor

slotted end, "R" for right-hand brakes and "L"

plunger can slide freely in housing bore. Tighten guide

for left-hand brakes. DO NOT mix at assem-

screw to 15-20lb.-ft.

bly.

Installation of Adjusting Plunger Assembly

f.

(1) The anchor plunger and seal is serviced as an

assembly. Refer seal replacement to direct support

maintenance.

CAUTION

(2) Install plunger and seal assembly into plunger

housing in the following manner (fig. 4-66).

DO NOT assemble seals Into plunger housing

first. This will result In complete lack of seal-

(a) Coat plunger bore with grease (item 17,

ing of Internal plunger housing components.

(1) Coat the inside and outside surfaces of both

(b) Coat entire plunger with grease (item

the adjusting plunger and the adjusting sleeve with grease

17, Appendix E). AIso pack the cavity behind the seal

(item 17, Appendix E). Also coat the plunger bore in the

assembly.

housing with grease.

(c) Insert plunger and seal assembly into

(2) Put the adjusting plunger into the plunger

housing with plunger keyway slot alined with guide hole in

plunger housing. The plunger must go all the way into the

housing. Make sure the plunger goes all the way to bottom

plunger bore and seat on the bosses at bottom of the

of bore and seats on the bosses. Aline keyway slot in

plunger housing.

plunger with guide hole in plunger housing.

Change 3

4-87