TM 9-2330-356-14

d.

Inspection and Repair.

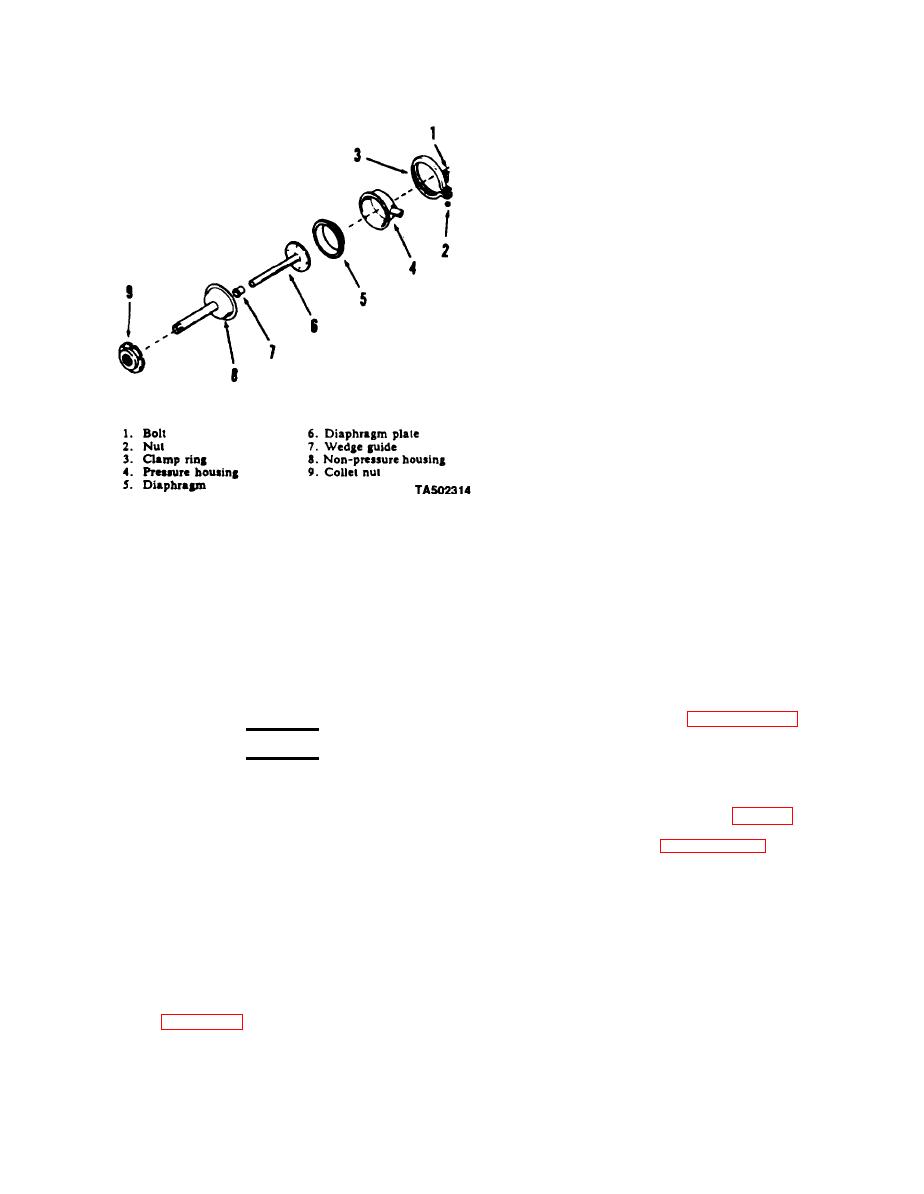

(1) Inspect wedge guide (7) for damage or wear.

If wedge guide is worn more than 25% of its thickness,

replace it.

(2) Check tube on non-pressure housing for pits,

grooves, or stripped threads. Replace housing if damage is

found.

(3) Inspect and replace diaphragm if it is tom or

cracked, or if rubber at sealing edge has become set or

distorted.

(4) Inspect diaphragm plate for bent push rod or

worn or cracked boot. Replace if not serviceable.

e.

Assembly.

(1) Install wedge guide (7) all the way onto end of

push rod of diaphram plate (6).

(2) Install collet nut (9).

(3) Clean non-pressure housing (8) with cement

and M970 except M970 SN TC-0843, TC-0844,

thinner or similar material in area where boot on

and TC-103 thru TC-178) (Standard).

diaphragm plate is to be cemented. Apply cement to

housing around tube end, then insert the diaphragm plate

(4) Remove diaphragm plate (6) and wedge guide

and push rod assembly into tube. Press boot into position

(7) from non-presure housing (8).

for cementing. Screw non-pressure housing (8) in place.

(4) Install new diaphragm (5) over plate and onto

(5) Unscrew collet nut (9).

non-pressure housing.

(6) Unscrew non-pressure housing (8).

(5) Install pressure housing (4), and secure with

clamp ring (3), bolt (1) and nut (2).

c.

Cleaning.

f.

leakage after installation by making full brake application

WARNING

and applying soapy water around clamp ring and

connections.

Dry cleaning solvent P-D-680 is toxic and

Brake Air Chamber M967, M969, and

flammable. Always wear protective goggles

M970 except M970 SN TC-0843, TC-0844, and TC-

and gloves, end us. only in a well-ventilated

103 thru T -178) (Fail-Safe Unit) (Fig. 6-5).

area. Avoid contact with skin, eyes, and

a.

clothes, and DO NOT breathe vapors. DO

NOT use near open flame or excessive heat.

Disassembly.

b.

The solvent's flash point is 100F-138F

(38C-59C). If you become dizzy while

(1) Remove nut (5) and bolt (4) from clamping

using cleaning solvent, Immediately get fresh

ring (6). Spread the clamping ring and remove from air

air and medical help. If solvent contacts eyes,

chamber.

immediately wash your eyes with water end

get medical aid.

(2) Carefully separate the fait-safe unit (1) from

the non-pressure housing (8). DO NOT disassemble the

(1) Clean metal parts with dry cleaning solvent

fail-safe unit. No repairs are authorized for this assembly.

(item 11, Appendix E).

(3) Carefully remove diaphragm (2) from

non-pressure housing (8).

(2) Clean diaphragm with mild soap solution.

Change 3