TM 9-2330-356-14

Section III. BRAKES AND BRAKE SYSTEM COMPONENTS

to shoe clearance is excessive if gage can be inserted

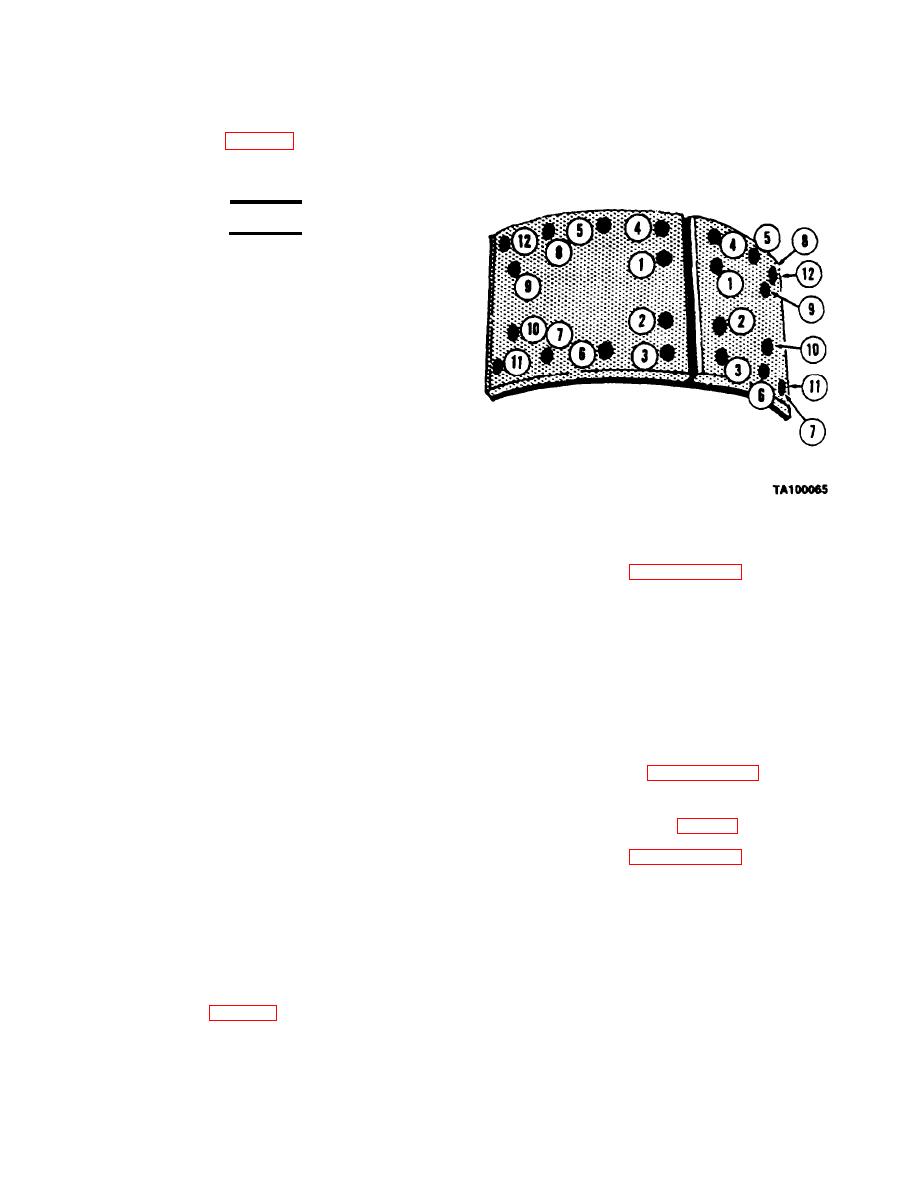

Brake Shoes (Fig. 6-3)

between shoe and lining.

a.

Disassembly.

WARNING

Due to asbestos hazard, do not grind off rivet

heads. Failure to follow this warning may re-

sult in injury or death to personnel.

(1) Punch rivets out from back side of shoe using

a hammer and a drift or punch.

(2) Remove linings from brake shoes.

b.

Inspection and Repair.

(1) Oil or grease saturated linings are not

reusable. Saturated linings indicate leakage in the axle

shaft seals.

(2) Grooving or uneven wear in brake linings in-

dicates a need for refacing or replacement of brake drum.

Brake Drums

(3) Inspect brake shoe for distortion, cracks or

damage. Replace the brake shoe if these conditions are

a.

found. Lining and shoe contact surfaces should be clean

and smooth.

b.

Reboring of Brake Drums.

(4) Use new rivets of the correct body diameter,

(1) Reboring is not recommended due to reduced

head size and shape, length, and material.

strength of refaced drums. If it is necessary to rebore a

drum, remove as little metal as necessary to true the

c.

Assembly.

friction surface.

NOTE

(2) If reboring requires removal of more than

Do not use combination linings.

1/16-inch of material, replace the drum.

(1) Make sure lining and shoe contact surfaces

c.

are clean.

Brake Air Chamber M867, M969, and

M970 except M970 SN TC-0843, TC-0844, and TC-

(2) Clamp lining to brake shoe with C-clamps

103 thru T -178) (Standard) (Fig. 6-4).

with rivet holes in both pieces alined.

a.

(3) Drive the rivets squarely into the holes with a

7/16-inch flat head drift.

Disassembly.

b.

(4) Position the C-clamps as close to the rivet

(1) Remove nut (2) and bolt (1) from clamp ring

holes as possible and make certain the lining is tight

(3). Spread the clamp ring and remove it from the air

against the shoe.

chamber.

(5) Working from heel to toe of brake shoe, form

(2) Hold diaphragm (5) to non-pressure housing

the rivet heads with the correct tubular rivet set. Follow

(8) and remove pressure housing (4).

the order shown in figure 6-3.

(6) Check lining installation with a 0.002-inch

(3) Carefully remove the diaphragm (5) from the

non-pressure housing (8).

feeler gage to ensure that lining and shoe contact. Lining

Change 3