TM 9-2330-356-14

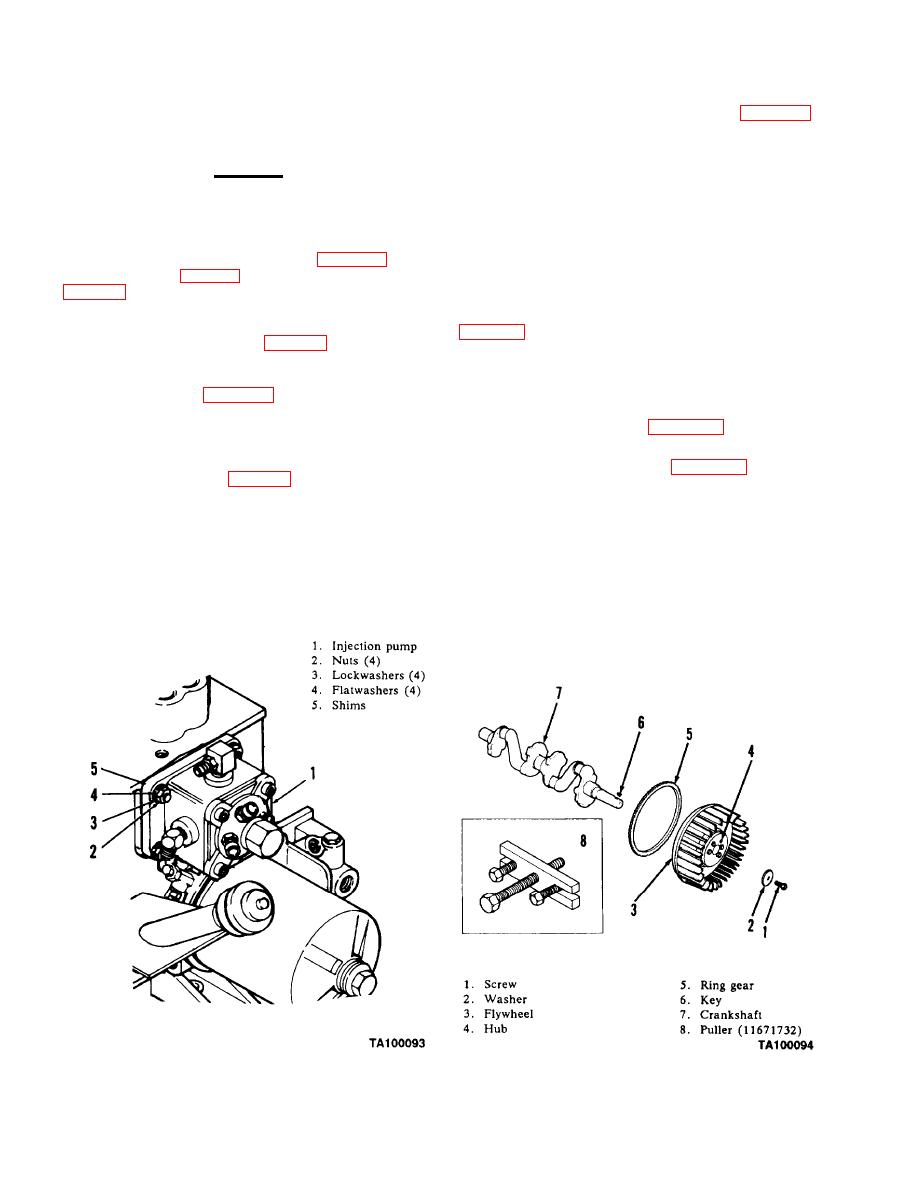

Remove four hexagon nuts (2, fig. 7-21),

f.

lockwashers (3), and flatwashers (4), holding injection

pump (1) to crankcase, and remove pump. Be careful to

CAUTION

retain the shims (5) from between the crankcase and

pump. The correct thickness of shims as stamped on the

All fuel connections must be plugged or

crankcase, above the injection pump, is important to

capped to prevent contamination.

proper pump operation; it provides the proper gear

backlash.

a.

Snap off governor linkage (1, fig. 7-14) from

injection pump (2, fig. 7-14) and governor control arm (3,

When removing a pump for replacement, record

g.

the button thickness and port closing dimensions as

stamped on the side of the pump mounting flange

Tag and disconnect high pressure lines at injector

b.

nozzles and at injection pump (fig. 7-15).

pump to the engine. If there is a standard button in the

pump, it may not be stamped or it will have the number 11

c. Tag and disconnect inlet and fuel return lines

stamped on the flange.

from injection pump (para 4-73).

Prior to removing the injection pump, position

d.

the number one piston on the compression stroke by

placing the PC mark on the flywheel in line with timing

a.

Remove blower assembly (para 7-14).

mark on gear case cover (fig. 7-78).

b.

Remove screw (1) and washer (2) attaching

e. Remove the timing hole screw on the left side of

flywheel to crankshaft.

pump mounting flange. Insert a 1/8-inch diameter brass

wire in the timing index hole. If the piston is on the

compression stroke, the wire will enter the index hole in

c. Install two screws in flywheel hub from puller(8)

the gear face. (Depth approximate 1 1/8-inch -GO,

to remove flywheel (3), ring gear (5), and key (6).

7/8-inch--NO GO.) If not, rotate the flywheel one

complete revolution and reinsert the wire.

Figure 7-22. Flywheel Assembly.