TM9-2330-368-14 & P

Section III. OPERATOR MAINTENANCE PROCEDURES

Page

Page

Electrical System . . . . . . . . . . . . . . . . . . . . ...3-9

Wheels and Tires . . . . . . . . . . . . . . . . . . . . ...3-10

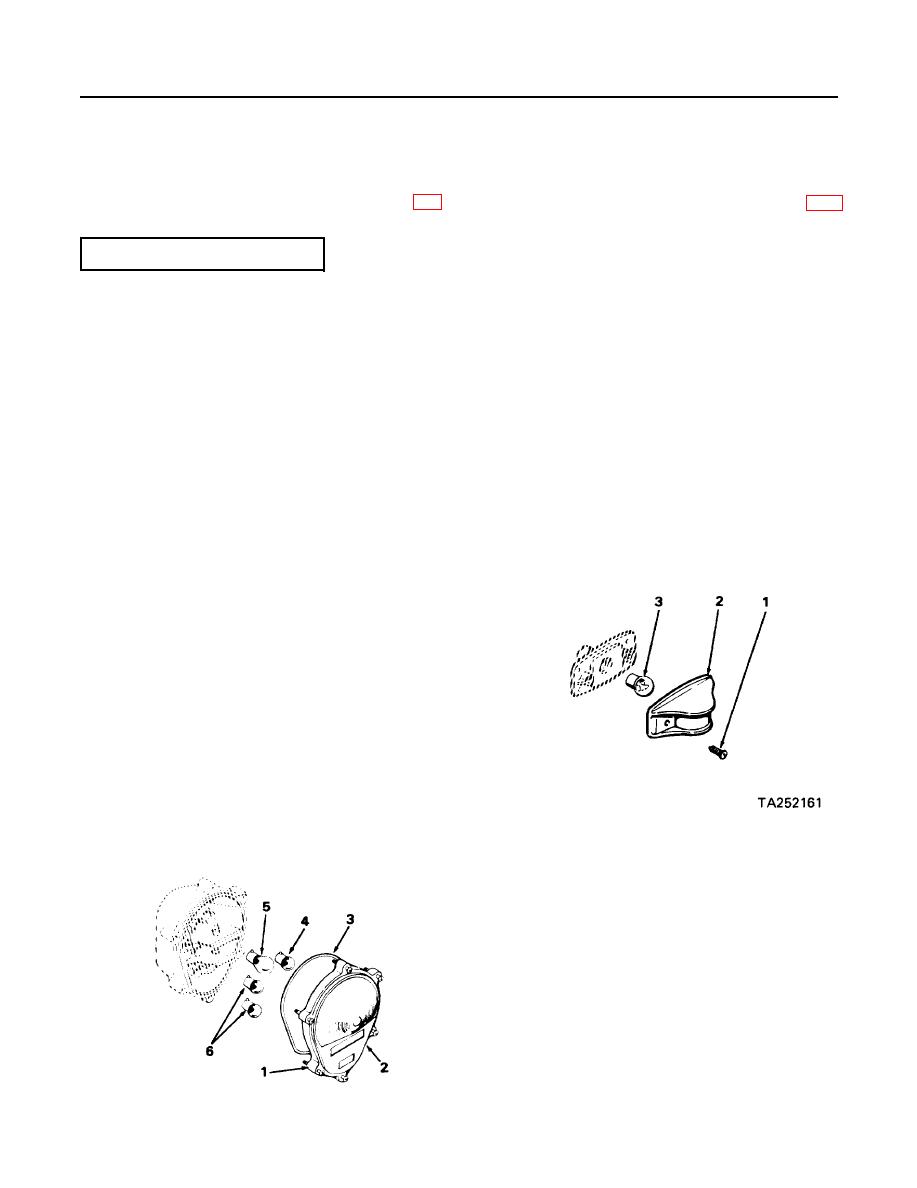

c. Clearance Marker Lights. Replace lamps as

3-5. ELECTRICAL SYSTEM

follows:

(1) Remove two screws (1) and light cover

(2).

a. General. Maintenance of the electrical sys-

(2) Remove lamp (3) by pressing in and ro-

tem at crew level is limited to replacement of the

tating lamp counterclockwise until it

lamps in the composite lights, marker lights and/or

releases; withdraw lamp from socket.

running lights.

(3) Insert new lamp in socket, press in and

b. Composite Lights. Replace lamps as fol-

rotate lamp clockwise until it locks in

lows:

place.

(1) Loosen six captive screws ( 1 ) and re-

(4) Position light cover (2) on body and in-

move lens assembly (2) with packing

stall two screws ( 1 ) to attach covers.

(3).

(2) Remove defective lamp (4, 5 or 6) by

pressing in and rotating lamp counter-

clockwise until it releases; withdraw

lamp from socket.

(3) Insert new lamp in socket, press in and

rotate lamp clockwise until it locks in

place.

NOTE

Be sure preformed packing (3) is

seated between light body and

lens assembly to seal the unit

properly.

(4) position lens assembly (2) on body and

tighten six captive screws (1 ).

3-9