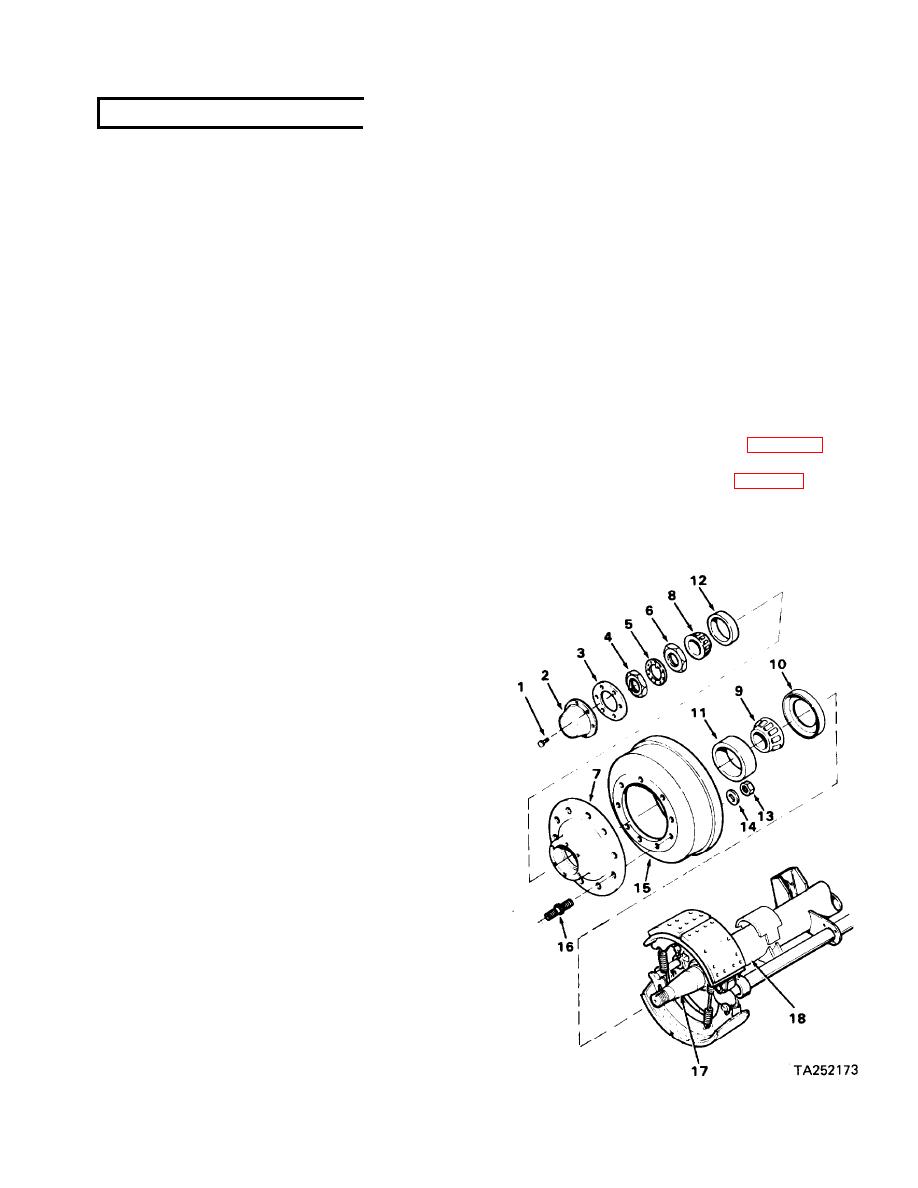

TM9-2330-368-14 & P

(9) Install inner spindle nut (6) on spindle

4-14. HUBS AND DRUMS (cont)

(17) and tighten nut against bearing

while turning brake drum (15) by hand.

(2) Inspect brake drum visually for deep

When there is a slight bind, back off in-

scoring, excessive wear (ridge) and

ner spindle nut 1/3 turn to allow free

other irregularities. Report condition

rotation of wheel.

to direct support maintenance.

(10) Install spindle lock (5) and outer spin-

(3) Inspect hub cap, nuts, lock and hub

dle nut (4). Tighten outer spindle nut

for cracks and other damage.

to 250-400 lb-ft.

(4) Inspect spindle for damaged threads,

(11) Repack hub cap (2) with grease GAA.

evidence of seizure and rough surfaces.

Report condition to direct support

(12) Install hub cap (2) and new gasket (3)

maintenance.

with six hex bolts (1).

d. Repair. Replace gasket, seal and all defec-

(13) Rotate brake drum (15) to assure free

tive parts,

movement without binding.

e. Installation.

(14) Uncage air brake chamber (para. 2-27 b).

(1) Install studs (16) in hub (7) if removed.

(15) Install wheels and tires (para. 3-6).

(2) Install inner bearing cup (11) in hub (7),

with narrow edge outward. Seat with

steel drift.

(3) Pack inner bearing cone (9) with grease

GAA and install in cup.

(4) To assure proper fit, place seal (10) on

spindle up to first rubber rib. The cor-

rect seal will not go on any further due

to designed interference.

(5) Place seal (10) on rear of hub (7) with

the words "OIL SIDE" facing inward.

Make sure that seal is straight. Using a

hammer and piece of flat hardwood,

tap the seal into hub until seal bottoms

out.

(6) Install outer bearing cup (12) in hub

(7). Pack hub cavity with grease GAA

up to level of inside diameter of outer

bearing cup (12).

(7) Install drum (15) on hub (7) with

back nuts (13) and washers ( 14) if re-

moved. Tighten nuts (13) to 300-330

lb-ft.

(8) Pack outer bearing cone (8) with grease

GAA and install in Cup (12).

NOTE

Be sure there is no brake drag be-

tween brake shoes and drum.

4-23