TM9-2330-368-14 & P

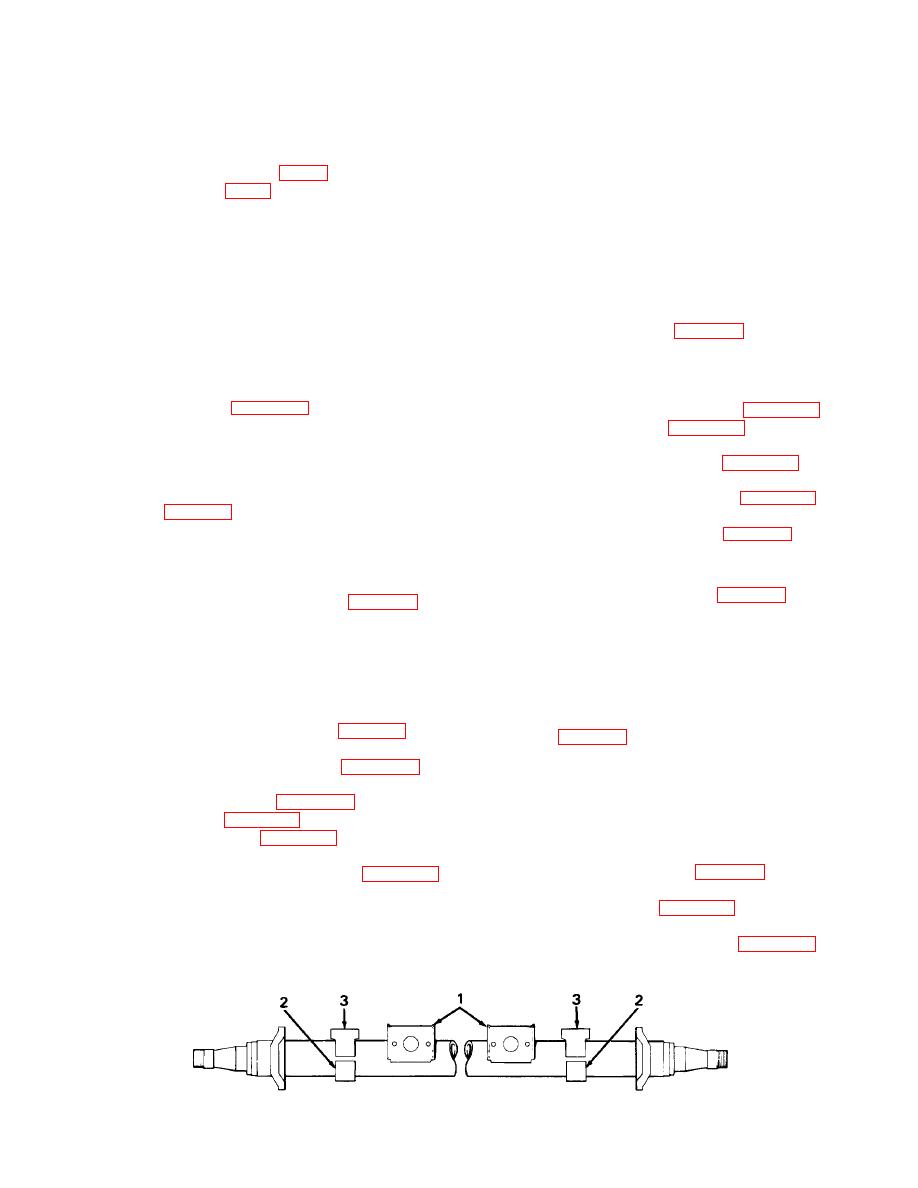

d. Inspection. Inspect axle for cracks, breaks,

broken or distorted brackets (1) and pads

5-8. AXLE

(2), corrosion and other damage.

Materials/Tools

e.

Repair.

Cleaning compound (item 1, app E)

(1) Straighten distorted air brake chamber

Wiping rag (item 10, app E)

brackets (1), spring mounting pads (2)

Welding machine

or axle bumpers (3) if possible. If

Welder tool kit

brackets, pads or axle bumpers cannot

Personnel: 2 required

be straightened, the axle must be

NOTE

replaced.

If an axle is to be removed for replace-

(2) Repair broken welds.

ment or repair, remove axle and sus-

pension together and disassemble after

(3) Repaint the axle (chapter 5, section III).

removal.

a. Removal.

Assembly.

f.

(1) Disconnect air hoses from brake air

(1) Install camshafts and bearings (para.

chambers (para. 4-16, steps 1 through 3).

4-15b (5)), slack adjusters (para. 4-15d

(3)) and brakes (para. 4-15a (5)).

(2) Use a suitable lifting device to lift

trailer and relax spring tension.

(2) Install hubs and drums (para. 4-14f).

(3) Remove torque arms and spring rollers

(3) Install air brake chambers (para. 4-16d).

(4) Install wheels and tires (para. 3-6c).

(4) Roll rear axle assembly with wheel and

suspension from underneath trailer.

Installation.

g.

(1) Install springs on axle (para. 5-6b, steps

(5) Remove springs from axle (para. 5-6a,

2 through 5).

steps 6 and 7).

b. Disassembly.

(2) Roll axle assembly with wheels and sus-

pension underneath HEMAT. Position

(1) Jack up axle assembly and place on

unit underneath suspension hangers.

jack stands.

(3) Install spring rollers and torque arms

(2) Remove tires and wheels (para. 3-6 b).

(4) Lower trailer.

(3) Remove hubs and drums (para. 4-14a).

(5) Connect air hoses to air brake chambers.

(4) Remove brakes (para. 4-15a (1)), slack

adjuster (para. 4-15d (1)), and camshafts

(6) Close drain cocks on air tanks.

and bearings (para. 4-15b (1)).

(7) Adjust torque arms (para. 5-7).

(5) Remove air brake chambers (para. 4-16

a).

(8) Uncage brakes (para. 2-27 b).

c. Cleaning. Clean axle thoroughly, using a

(9) Adjust air brake chamber (para. 4-16b).

brush and water to remove mud, and clean-

ing compound to remove grease and oil.

(10) Adjust brakes (4-15c).

Wipe off.

TA252207

5-8