TM 9-2330-381-14

1.

Clean all parts removed in degreaser tank with cleaning compound solvent and wire brush as necessary.

2.

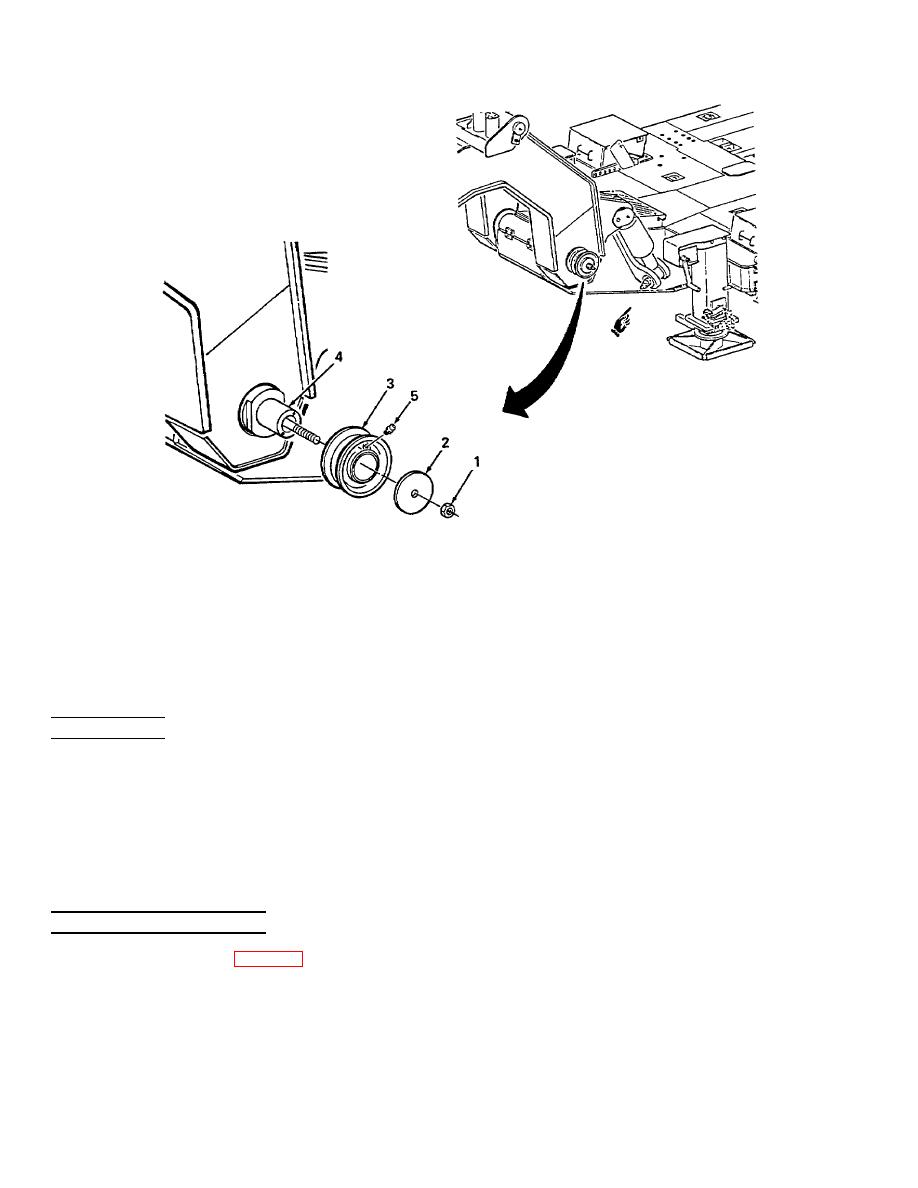

Inspect pulley (3) for corrosion, evidence of cracks, excessive dents, gouges, warping, and peeling of painted

surfaces. Remove any nicks, burrs, or corrosion from inner diameter of pulley (3) with crocus cloth. Check for

loose, missing, or damaged attaching hardware. Replace defective or missing components as required.

3.

Inspect machined surface of pivot pin shaft (4) for surface deterioration, burrs, scratches, or gouges that could

interfere with mating inner diameter of pulley (3) and cause sticking or irregular operation. If pivot pin shaft (4)

has any of the above, notify DS Maintenance.

INSTALLATION

1.

Install lubrication fitting (5) into pulley (3) and apply grease to inner diameter of pulley (3) of pivot pin assembly

(5).

2.

Apply grease to surface of pivot pin shaft (4) and install pulley (3) on shaft.

3.

Install cover (2) and locknut (1).

4.

Wipe off excess grease with rag.

FOLLOW-ON MAINTENANCE

Lubricate pivot pin sheave (para. 3-3).

Change 1 4-307