6.

Set stop finger so that it will pick up the cutter

before the cutter engages the grinding wheel. See

Always adjust the centers so that the cutter can

rotate freely and yet not have any play or looseness. If the

cutter fits loosely on the centers it will be impossible to get

an accurate grinding job.

GRINDING SPUR BITS

1.

Set up grinder with work-head.

2.

Swing work-head to the right.

3.

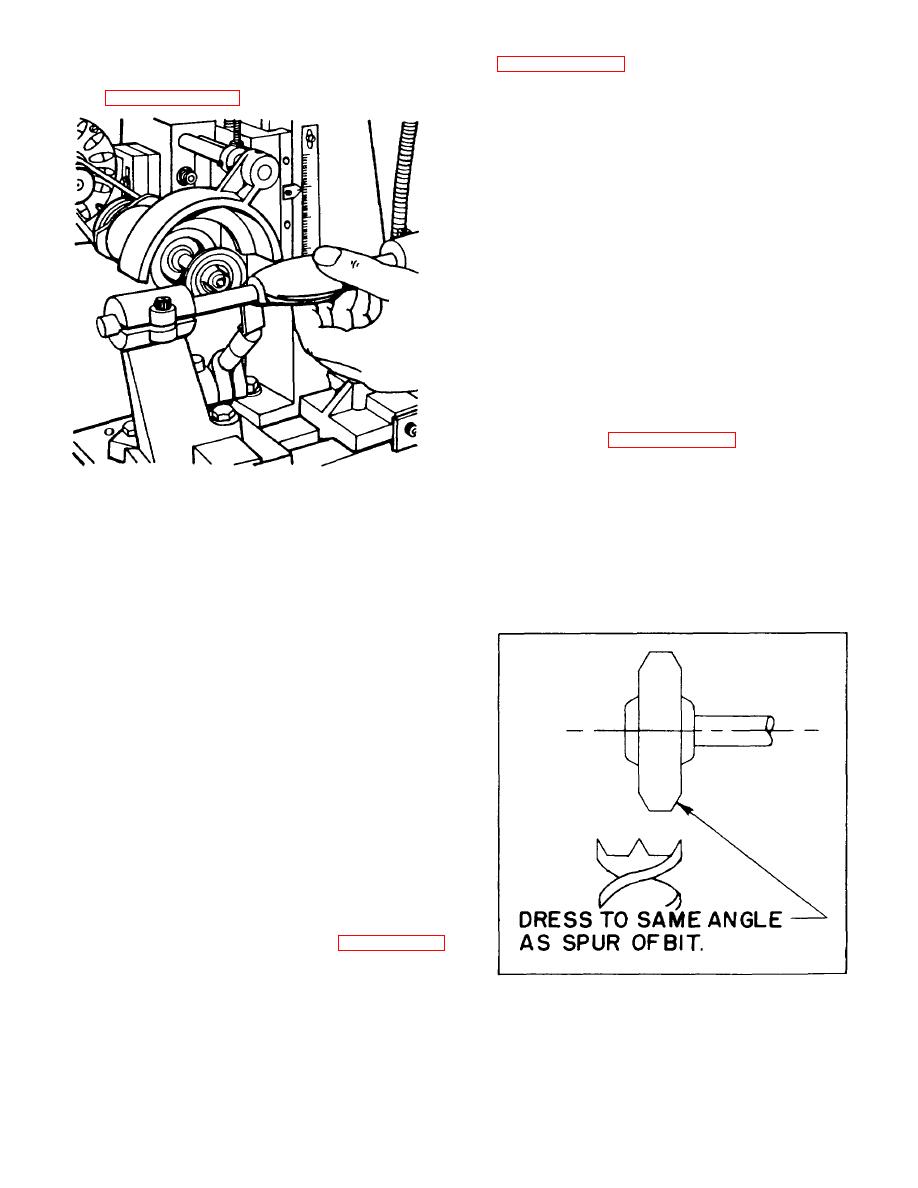

Swing work-head up to a vertical position. See

illustration No. 25.

4.

Next select the collet necessary to mount spur bit

into collet head.

5.

Select a straight grinding wheel of the proper

thickness and dress the corners so that the

grinding wheel matches the end of the spur bit.

See drawing illustration No. 24.

6.

Re-adjust work-head as needed to permit grinding

ILLUSTRATION NO. 23

wheel to clear through end of spur bit and give

GRINDING A SPIRAL PLANER CUTTER

proper clearance.

7.

Make sure that the point of contact between stop

7.

Turn on grinder motor and grind one half of the

finger and cutter as well as between cutter and

end of spur bit by feeding grinding wheel down

grinding wheel are very close together. Caution it

onto the snug bit. See illustration No. 25. Be sure

is very important to get stop finger to contact the

to back up on feed handle to take slack out of feed

work piece as near to the same point that the

screw.

grinding wheel contacts the work. That is, if the

stop finger is too far ahead of the grinding wheel,

the cutter will drop off of the stop finger too soon

at the end of the grinding stroke. This will cause a

bell shape to be ground on the end of the spiral If

the stop finger is placed too far behind the

grinding wheel, the cutter will engage the grinding

wheel before the stop finger can pick it up.

8.

Turn on grinder motor and take a very light pass

on the cutter. Check the contact between grinding

wheel and cutter.

GENERAL NOTES ON GRINDING STRAIGHT AND

SPIRAL CUTTERS

In some cases, after grinding the cutter, the stop finger is

adjusted down a small amount and the cutter is re-ground.

This procedure will leave a narrow land on the cutter. The

land should be from 1/32 to 1/16 wide, see Illustration No.

18. This grinding procedure will produce a primary and

secondary clearance angle.

ILLUSTRATION NO. 24

DRESSING GRINDING WHEEL TO MATCH SPUR BIT

When grinding spiral or straight planer knives

always keep a light pressure on the cutter with your hand

so that the cutter will track on the stop finger. That is,

rotate the cutter against the stop finger and keep a light

pressure on the cutter as it travels along the stop finger.

13