on the grinding wheel, going completely around

the reamer before moving the grinding wheel to a

new setting.

6.

Remove as little material as possible to restore

cutting edges of reamer.

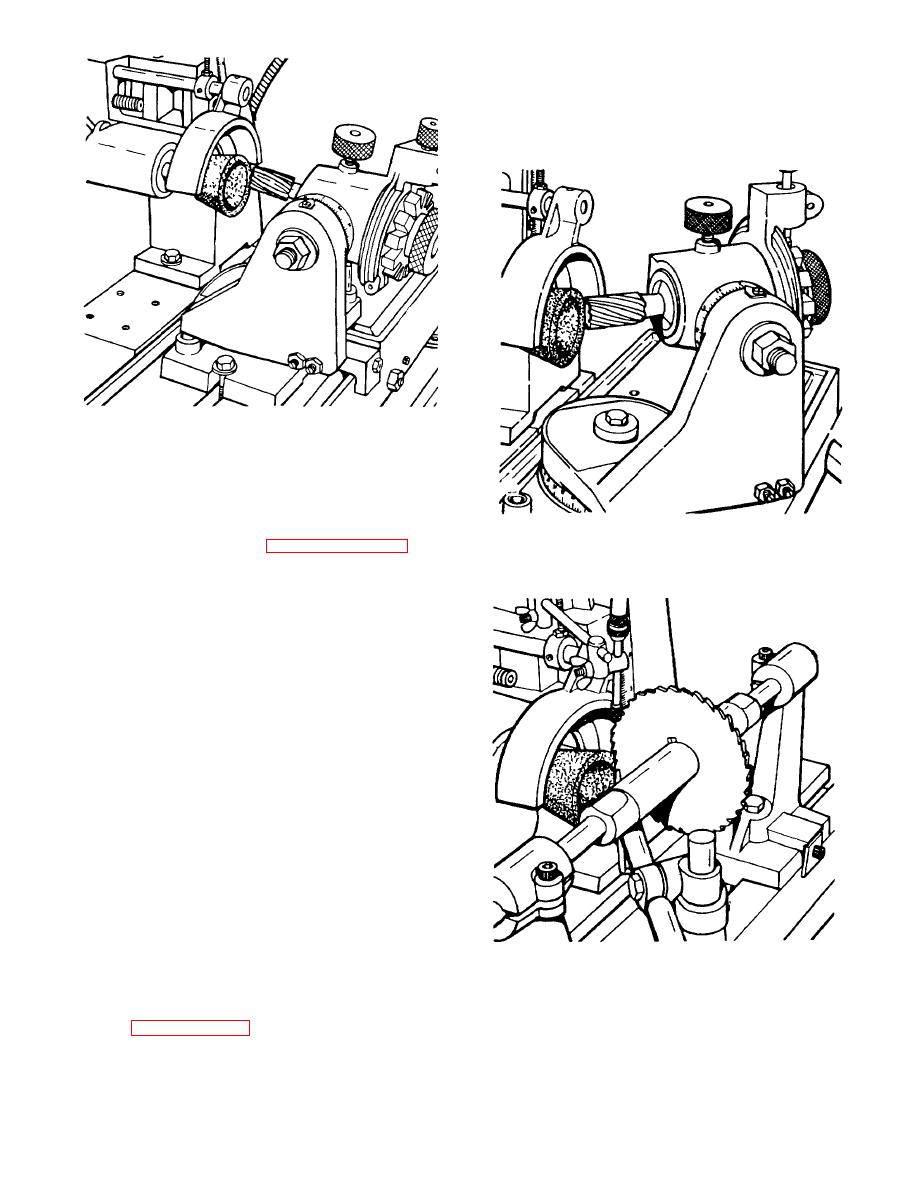

ILLUSTRATION NO. 29

GRINDING END OF SPIRAL END MILL CUTTER

4.

On some end mills the center at the end of the

cutter must be relieved. To accomplish this, set

work-head angle bracket at 45 and bring flaring

cup grinding wheel to the same elevation as the

ILLUSTRATION NO. 30

end of the cutter. See illustration No. 30 Now

RELIEVING END OF SPIRAL END

bring end mill up very close to grinding wheel and

MILL CUTTER

lock the grinder table. Next turn on the grinder

motor and slowly feed the grinding wheel into the

end of the cutter and at the same time, rotate

cutter in the work-head. This procedure will

relieve the end of the cutter and produce a

spherical relief with a radius nearly equal that of

the grinding wheel used to produce the radius.

GRINDING REAMERS

General: A reamer is ground only on the end and not on

the outside diameter. If the outside diameter is ground,

the reamer will produce a smaller hole than before

grinding.

TO GRIND END OF REAMERS

1.

Mount sub-table and centers onto grinder table.

Swing sub-table out approximately 45 and lock.

2.

3.

Set-up spring loaded stop finger and mount stop

finger base to sub-table or grinder table.

ILLUSTRATION NO. 31

GRINDING A SLITTING SAW

4.

Mount a flaring cup grinding wheel on to spindle

shaft with face of wheel towards front of grinder.

5.

When you are satisfied with your set-up grind the

primary clearance angle first using very light feeds

15