Rotate router bit for clearance angle and lock table

lock and work-head lock knob. See drawing

6.

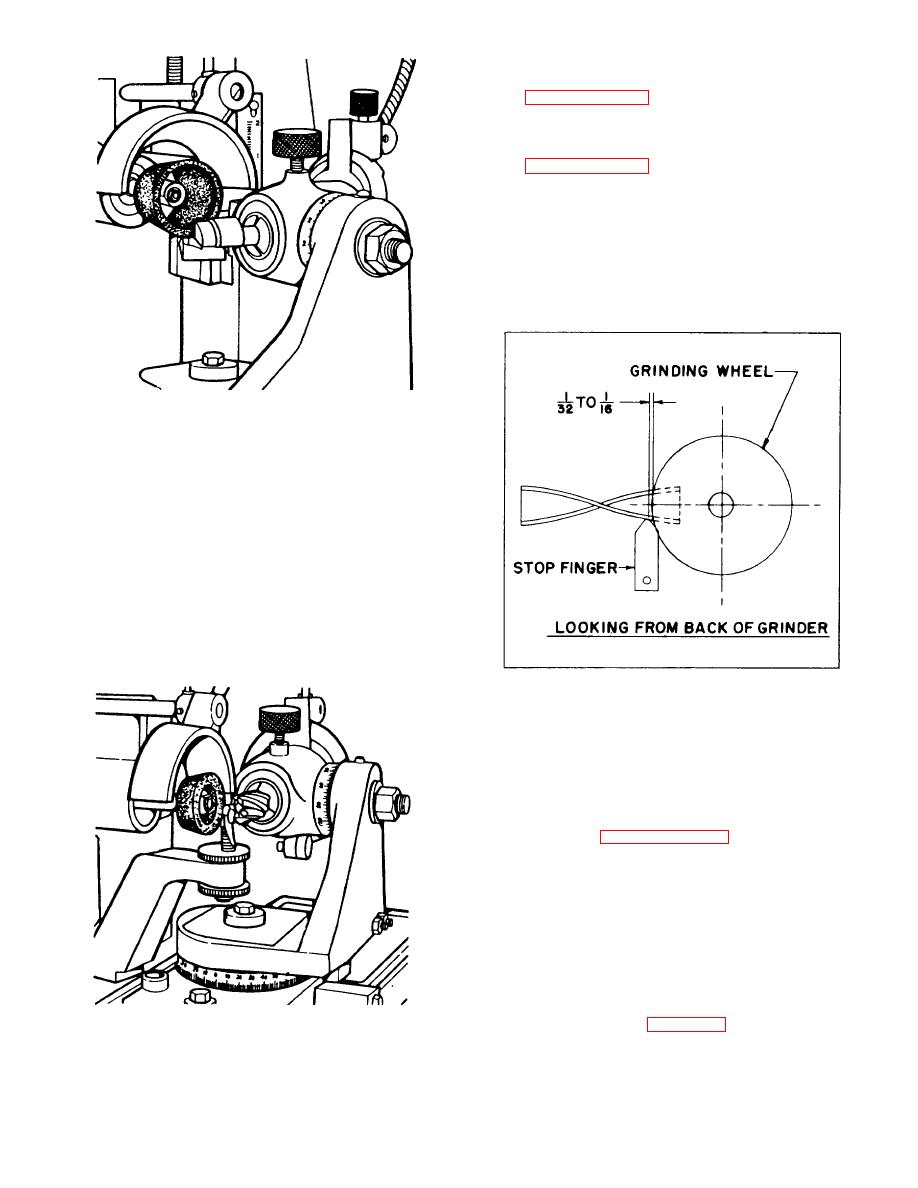

Set up stop finger so that finger is supporting the

router bit ahead of the grinding wheel. See

7.

Loosen table lock and traverse table to left until

stop finger comes to end of router bit flute. Set

right hand stop rod.

8.

Dry run cutter over stop finger to see that stop

finger is set correctly. Make sure that index pin

and collet tube lock are released and work-head

collet can rotate freely.

ILLUSTRATION NO. 16

GRINDING FLUTE OF STRAIGHT ROUTER BIT

GRINDING SPIRAL HIGH SPEED ROUTER BITS

1.

In general, if the cutter has centers, it should be

mounted on the machine using centers and

subtable.

2.

Work-head Mount cutter in work-head using

appropriate collet.

3.

Swing work-head to the right and locate against

stop pin.

4.

Mount flaring cup grinding wheel with face of

wheel toward front of grinder.

ILLUSTRATION NO. 18

9.

Bring router bit onto stop finger and turn on

grinder motor. Bring grinding wheel up and just

touch the router bit. Traverse router bit off of the

stop finger and check the surface ground. If you

are grinding only on the cutting edge of the router

bit, lower the stop finger. If you are not grinding

on full top width of cutting edge, raise the stop

finger. See illustration No. 19.

10.

After you are satisfied with your set-up, grind each

land of the cutter for each grinding wheel setting.

That is, grind each land and then feed grinding

wheel in and then go around cutter again. Use an

in-feed of about (.0005) one-half thousandth on

finish pass.

11.

To grind the ends of the spiral cutter, use the

same set-up as for straight router bits. See

ILLUSTRATION NO. 17

illustration No. 15 and No. 22.

GRINDING A SPIRAL CUT

5.

Position end of router bit next to grinding wheel.

10