TM 9-3431-254-14&P

bearing greased every day before starting. Use

general (lube) grease, MIL-L-10924.

Rockford PTA-4856 units have a sealed pilot bearing

and require no external lubrication. Obsolete

PTA-4819 units have a pilot bearing grease fitting at

the end of the drive shaft and are lubricated same as

the linkage slightly and will enable the carburetor

the housing bearing.

throttle lever to bounce back from the stop pin rather

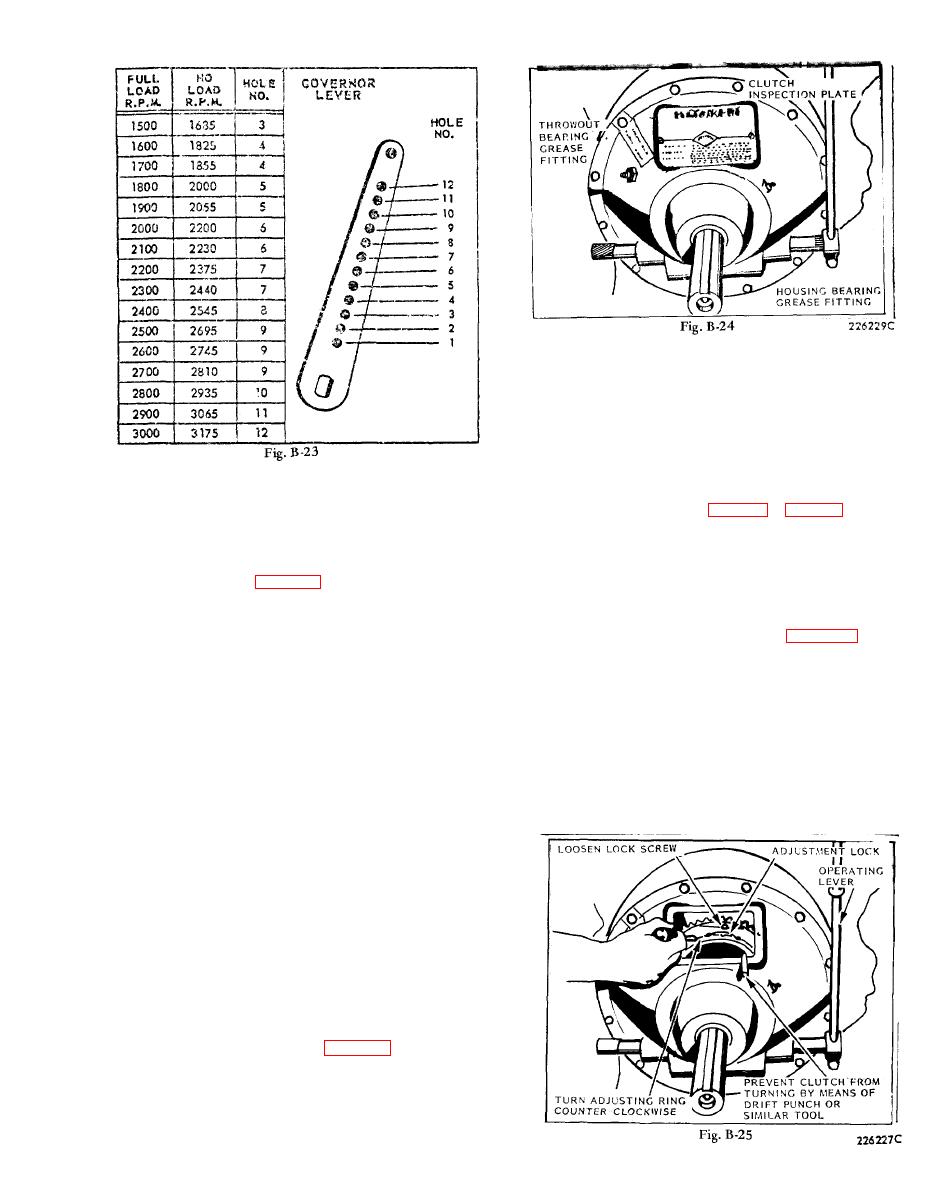

CLUTCH ADJUSTMENT (Fig. B-25 or Fig. B-26)

than jam against the pin, when a load is suddenly ap-

plied to an idling engine. This will eliminate exces-

If the clutch begins to slip it should be readjusted,

sive wear on the threads in the carburetor throttle

otherwise it will become overheated and damaged.

swivel block.

First, remove the clutch inspection plate and release

The governor lever, Fig. B-23, is furnished with 12

the clutch operating lever. For the Rockford clutch,

holes for attaching the governor spring. It is very im-

turn engine over by means of the hand crank until the

portant that the spring is hooked into the proper hole

clutch adjustment lock is visible thru the inspection

to suit the speed at which the engine is to be opera-

opening in the clutch housing, see Fig. B-25. The

ted. The Governor Lever Chart shows the full load

clutch must be held stationary, either by means of a

and no load speeds of the engine and the hole cor-

drift punch wedged in place as shown, or by some

responding thereto, for either a fixed speed, a vari-

convenient method of keeping the take-off shaft from

able speed or two speed (over-center idle control)

turning. Loosen screw holding the adjustment lock in

governor. Note that the full load speed is less than

place. Insert a screw driver in one of the notches and

the no load speed and this must be taken into consi-

turn the adjusting ring in a counter-clockwise direc-

deration when readjusting the governor. As an ex-

tion, one notch at a time, until a very firm pressure is

ample; if the engine is to be operated at 2000 revolu-

required to engage the clutch with the operating lever.

tions per minute under load, the spring should be

Tighten adjusting lock screw and mount inspection

hooked into the 6th hole in the governor lever and the

cover.

spring tension adjusted, by means of the adjusting

screw, to run 2200 R.P.M. under no load. The speed

at full load will then be approximately 2000 revolu-

tions per minute.

A tachometer or revolution counter should be used

against the crankshaft to check speed while adjust-

ing the governor spring tension. Tightening the ad-

justing screw locknut will give higher speeds, while

loosening the locknut will lower the spring tension

and reduce the R.P.M.

CLUTCH AND REDUCTION UNITS

The clutch available on this engine is of the dry disc

type. No oil should be put into the clutch housing,

but grease gun fittings are provided for periodic bear-

ing lubrication. The housing bearing should be greased

every fifty hours of operation and the clutch throwout

ROCKFORD CLUTCH ADJUSTMENT

B-19