TM 55-1930-208-10

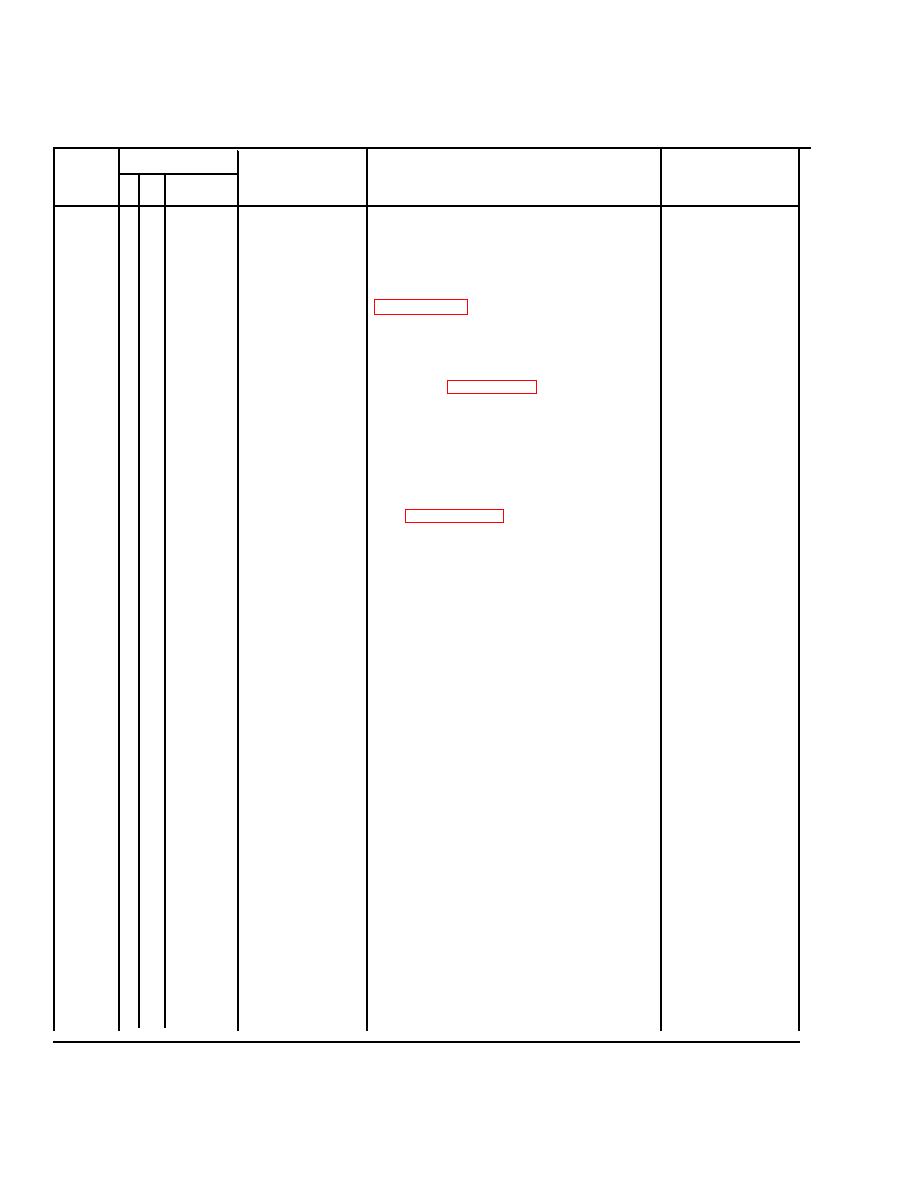

Table 2-4. Operator/Crew Preventive Maintenance Checks and Services (PMCS

INTERVAL

PROCEDURES

EQUIPMNET IS

ITEM

ITEM TO BE

CHECK FOR AND HAVE REPAIRED

NOT READY/

NO

B

D

A

INSPECTED

OR ADJUST AS NECESSARY

AVAILABLE IF:

43

SHAFT ASSEM-

Inspect shaft assembly for

Universal yoke is

BLY, UNIVER-

secure mounting or damaged

damaged.

SAL

universal yoke. Notify

direct support maintenance.

Service in accordance with

44

PUMP, TRANS-

Inspect pump for secure

FER

mounting or damage. Noti-

fy direct support mainte-

nance. Service in accor-

dance with paragraph 3-1.

45

VALVE, RELIEF

Visually inspect valve for

damage. Notify direct sup-

port maintenance.

46

LIGHTING

Inspect lights for secure

Lights are inop-

mounting hardware, broken

erable.

lens, or burnt out lamp

unit. Repair in accordance

with paragraph 3-25.

47

PIPING,

Visually inspect for leaks

TRANSFER

or damage. Notify general

support maintenance.

48

VALVES, CARGO

Check valves for ease of

Class III leak is

operation and signs of

present.

leaks. Notify general sup-

port maintenance.

49

GAGE, PRESSURE Visually inspect for damage

to gage or leaks. Notify

direct support maintenance.

2-13