TM 9-2330-356-14

(13) Repeat steps (8) through (12) for other side.

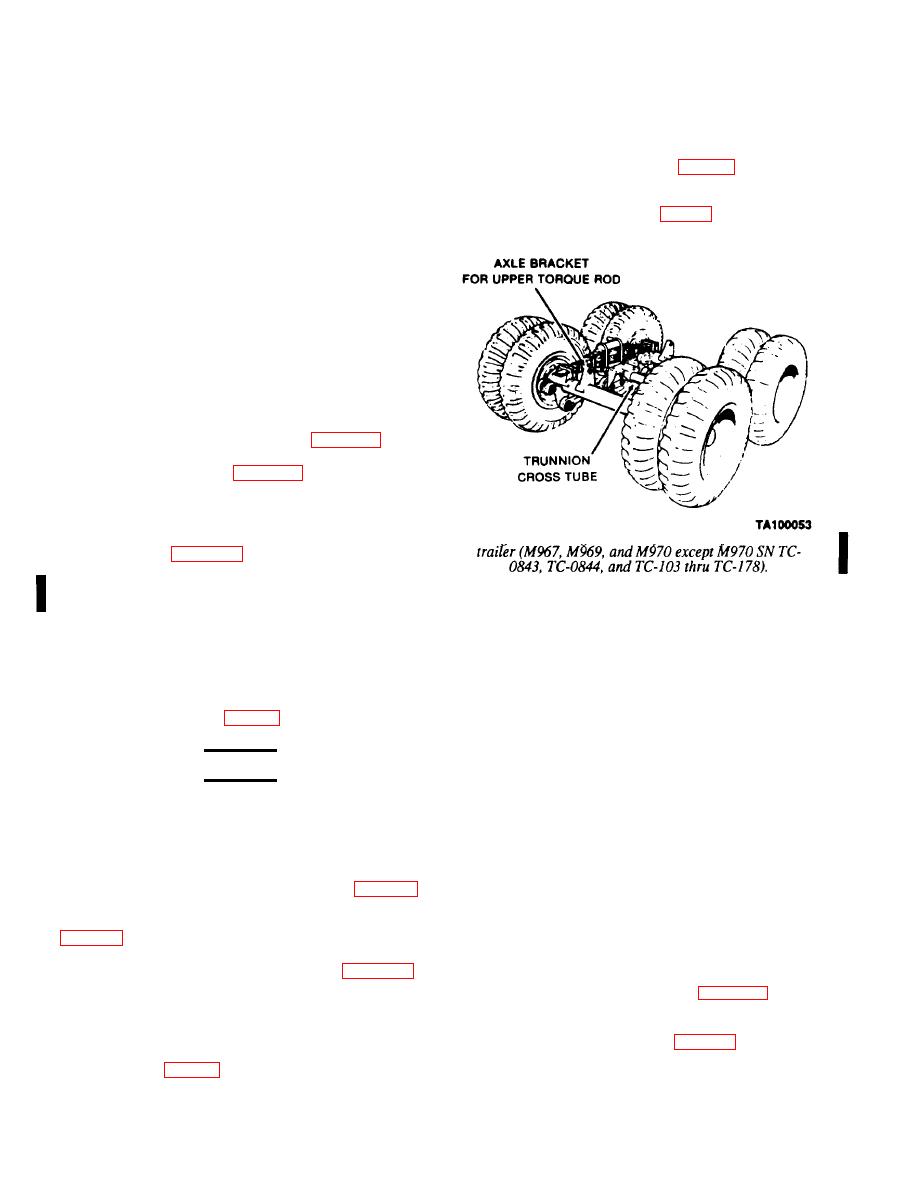

(5) Remove jacks from under trunnion cross

tube. Raise semitrailer another 16-inches, or until there is

(14) Slowly lower axle.

enough clearance to roll the bogie assembly and wheels

out from under rear of semitrailer (fig. 5-6).

b.

Installation (Fig. S-S).

(6) Lower semitrailer onto supports or cribbing

(1) Move axle into position under semitrailer.

after bogie assembly is removed (fig 5-3).

Raise and revolve axle into position on ends of suspension

springs.

(2) At each end of axIe, loosely install spring

seats, adjustment plates, cushioning pads, and spring end

caps with two U-bolts, four washers, and four nuts.

(3) At each end of axle, loosely install spring end

cap to spring seat on axle with four bolts, four washers, and

four nuts.

(4) Tighten all nuts evenly to 200-320 lb.-ft.

(5) Install brake air chambers (para 4-38).

(6) Install wheels (para 4-49).

(7) Remove supports and jacks.

(8) Tighten wheel nuts to proper torque and in

proper sequence (pars 4-49).

b.

Installation.

except M970 SN TC-0843, TC-0844, and TC-103

thru TC-178).

a.

Removal.

NOTE

The upper torque rods on the front and rear

(1) Position semitrailer on hard, level surface

axles will be toward the right aide (curbside)

with front resting on landing gear. Raise rear of

of the semitrailer If the bogie assembly Is

semitrailer with an overhead crane or A-frame support

installed correctly.

until all wheels are approximately l-inch off the ground.

Block the frame securely (fig. 5-3).

(1) Raise rear of semitrailer to allow bogie

assembly to roll under frame from rear. With front of

WARNING

bogie assembly toward front of semitrailer, roll bogie

assembly into position under support brackets for

Release air pressure from both air reservoirs

trunnion cross tube.

before doing any work on brake lines or other

pressurized air lines.

(2) Lower the semitrailer to within 1-inch of the

trunnion cross tube bracket. Ensure that the holes of the

support brackets are in line with holes in trunnion cross

(2) Release air from both air reservoirs by

tube bracket.

opening drain cocks on bottom of reservoirs (fig. 4-79).

Tag and disconnect eight hoses from brake air chambers

(3) Install eight bolts, washers, and nuts. As you

on both axles. Manually release the fail-safe springs

tighten the nuts, jack up the trunnion cross tube brackets

to seat the support brackets. Tighten nuts to

450-650 lb.-ft. Remove jacks.

(3) Remove two upper torque rods (para 5-11).

(4) Install upper torque rods (para 5-11).

(4) Position jacks under mounting brackets of

trunnion cross tube (one jack under each bracket) to

(5) Connect hoses to brake chambers as tagged.

support weight of trunnion cross tube. Remove four nuts,

Manually release fail-safe springs (pars 2-4).

washers, and bolts which fasten each mounting bracket to

support bracket (fig. 5-3).

(6) Remove supports and jacks.

Change 3