TM 9-2330-356-14

(4) Apply a thin coat of petrolatum (item 23,

(6) Rotate lever (41) while holding sleeve of

control unit assembly (4). Shaft must turn freely. If a

binding condition exists, wash assembly in a cleaning

assemble it to the hub on the face gear (28).

agent, and repeat procedure. If binding condition is still

present, injection pump must be replaced. Also ensure

(5) Carefully center spring ring (27) on hydraulic

head assembly.

that weld holding lever to shaft is intact.

(6) Position the face gear (28) and thrust washer

(7) The flat end of plunger sleeve pin (5) must be

(29) over the end of the plunger (35), and aline the head of

checked for clearance in the mating slot of the plunger

the plunger sleeve pin (5) with its mating slot located on

sleeve. If the clearance is greater than 0.0015-inch, the

the inside of the face gear (28).

injection pump must be replaced.

c.

Reassembly (Fig. 7-46).

CAUTION

Do not use extreme pressure. If gear will not

snap Into place easily, remove gear and

CAUTION

check to see that spring ring (27) Is centered,

and that plunger drive pin (1, fig. 7-50) is

Be careful not to damage O-ring gaskets.

properly alined.

(7) Press the face gear (28, fig. 7-46) onto the

(1) After all parts have been thoroughly cleaned

hydraulic head (17). Ensure that the spring ring (27) snaps

and inspected, dip the individual parts in clean diesel fuel

into its mating groove in the face gear (28). Manually

(item 14, Appendix E).

operate the plunger up and down. Free movement of the

plunger indicates that the face gear has been correctly

(2) Invert the hydraulic head (17, fig. 7-46) and

assembled to the hydraulic head.

place it on a clean bench so that the head locating slot is

forward.

(8) With head still in an inverted position, raise

plunger (35) to its highest position.

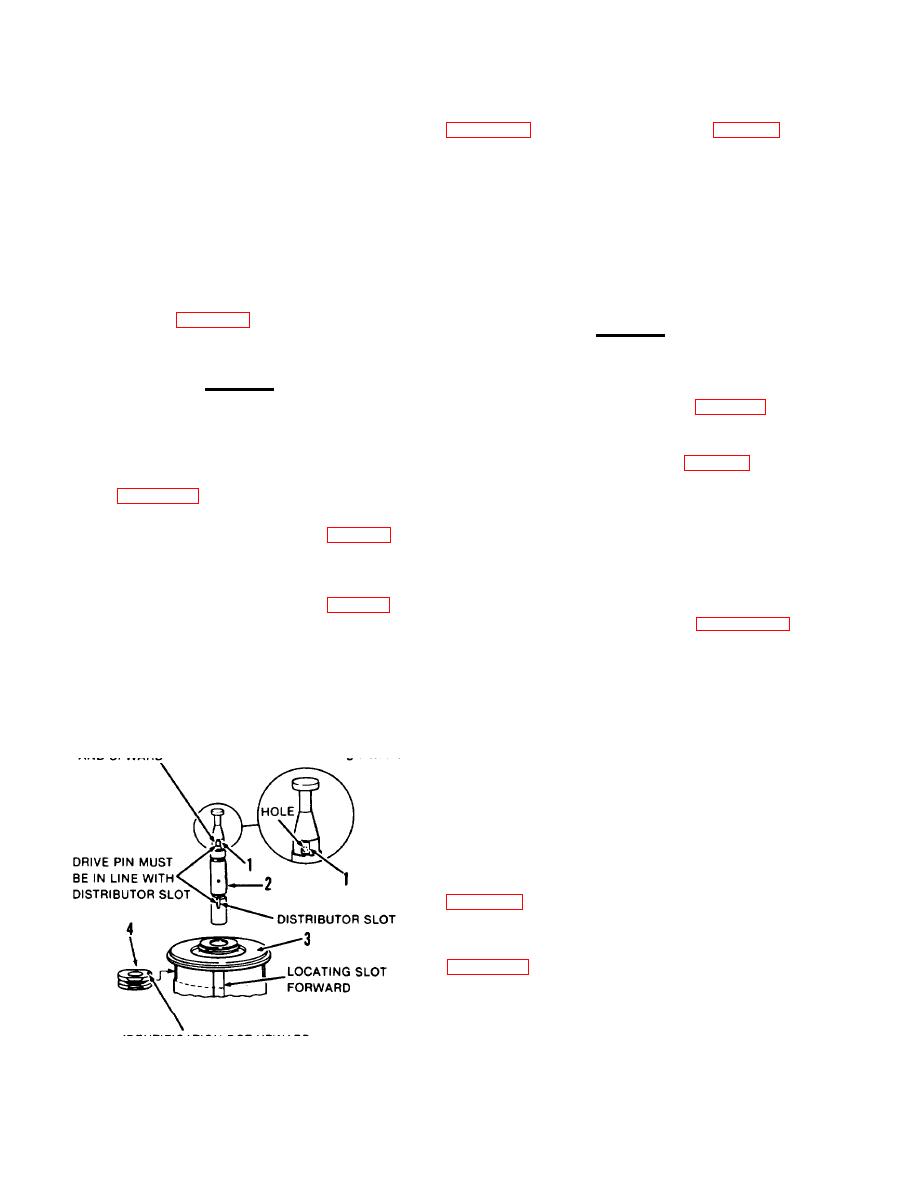

(3) Aline the plunger drive pin (1, fig. 7-50) into

the plunger (2) so that the head of the plunger drive pin is

(9) Apply grease (item 17, Appendix E) to

in line with the distributor slot. Turn the plunger drive pin

exposed portion of plunger to keep it in its highest

until its long side is parallel to the length of the plunger

position.

with long end up.

(10) Install spring (26) and spring retaining washer

(24). Snap spring seat (25) into place on the head of

LONG SIDE OF HEAD PIN

1. Plunger drive pin

2. Plunger

plunger (35).

MUST BE PARALLEL TO

3. Hydraulic head

LENGTH OF PLUNGER

4. Plunger sleeve

AND UPWARD

(11) Install the plunger button (23) onto the end of

the plunger and secure it by snapping the spring ring (22)

into its mating groove in the lower spring seat (25).

(12) Ensure that the button spring ring (22) fits

tightly into its groove in the lower spring seat (25). Loose

spring rings (22) must be replaced.

(13) Apply thin coat of petrolatum (item 23,

into the face gear (28).

(14) Apply a thin coat of petrolatum (item 23,

Insert O-ring into the head bore of the pump housing (6).

Install the O-ring into its groove on the upper portion of

the hydraulic head. Ensure that O-rings seat properly.

TA100121

(15) Clamp pump mounting fixture in a vise,

install pump housing fixture, then carefully insert the

7-44