TM 9-2590-209-14&P

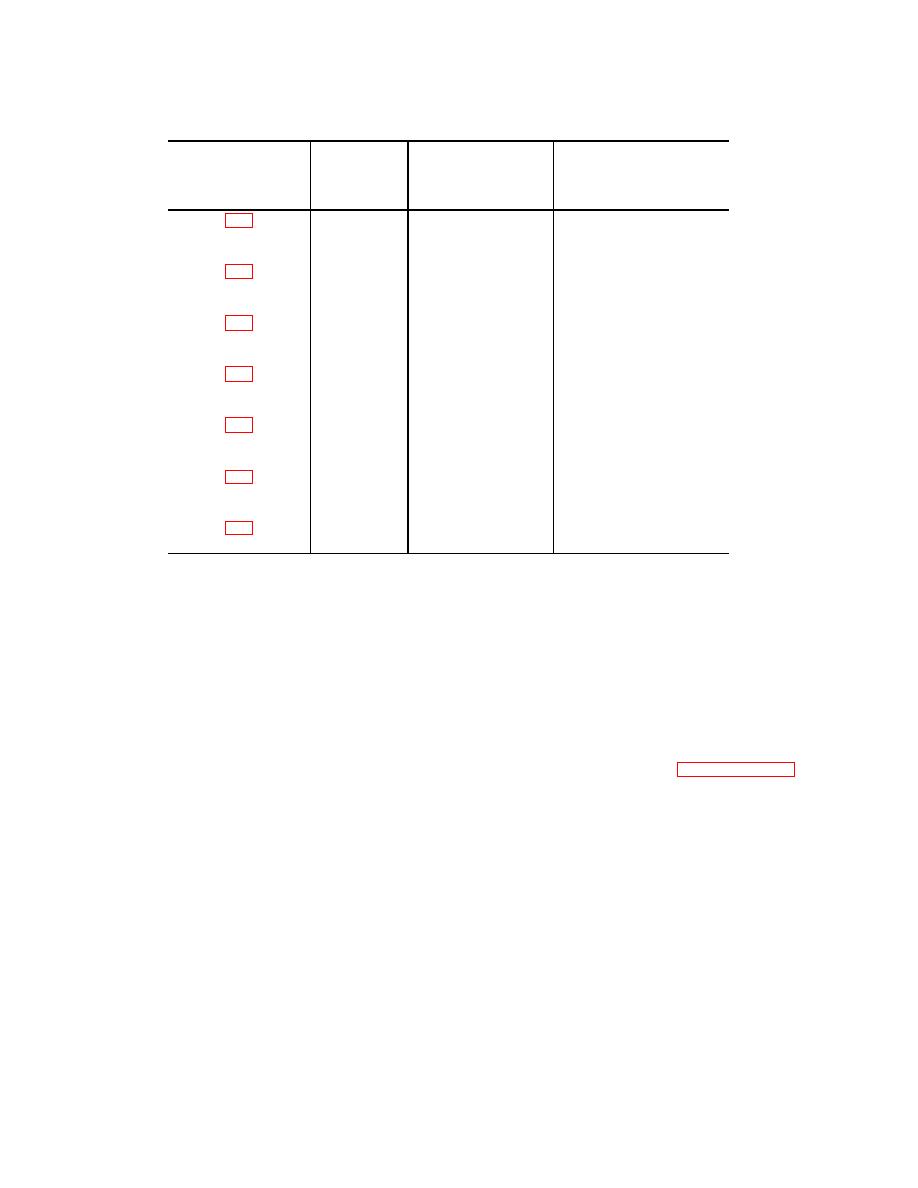

Table 6-1. Repair Standard for Magnetic Clutch

Ref-

Figure

erence

Point of

Number

Letter

Measurements

Wear Limits

A

Bearing OD

2.4404 to

2.4409

B

Bearing ID

1.1807 to

1.1811

C

Shaft OD

1.1812 to

1.1806

D

Shaft OD

1.3781 to

1.3785

E

Magnet Body

2.4409 to

Half ID

2.4416

F

Bearing OD

2.4404 to

2.4409

G

Bearing ID

1.3775 to

1.3780

c. With the magnetic clutch actuated, use a feeler

Five degrees of nut travel will change air gap

gage to check air gap between magnet body half and

approximately 0.001 inch.

clutch body half at 90degree intervals around clutch.

The average of four feeler gage readings should be

e. Adjust air gap until four feeler gage readings

0.0150.018 inch. If this average is obtained, the clutch is

average 0.015-0.018 inch with clutch actuated. Tighten

adjusted properly. If not, proceed to step d.

screw.

d. Loosen screw in adjusting nut and turn adjusting

f. Turn off power, and disconnect power supply

nut clockwise to increase air gap, or counterclockwise to

from magnetic clutch.

decrease

air

gap.

6-11.

6-4