TM 9-2590-209--14&P

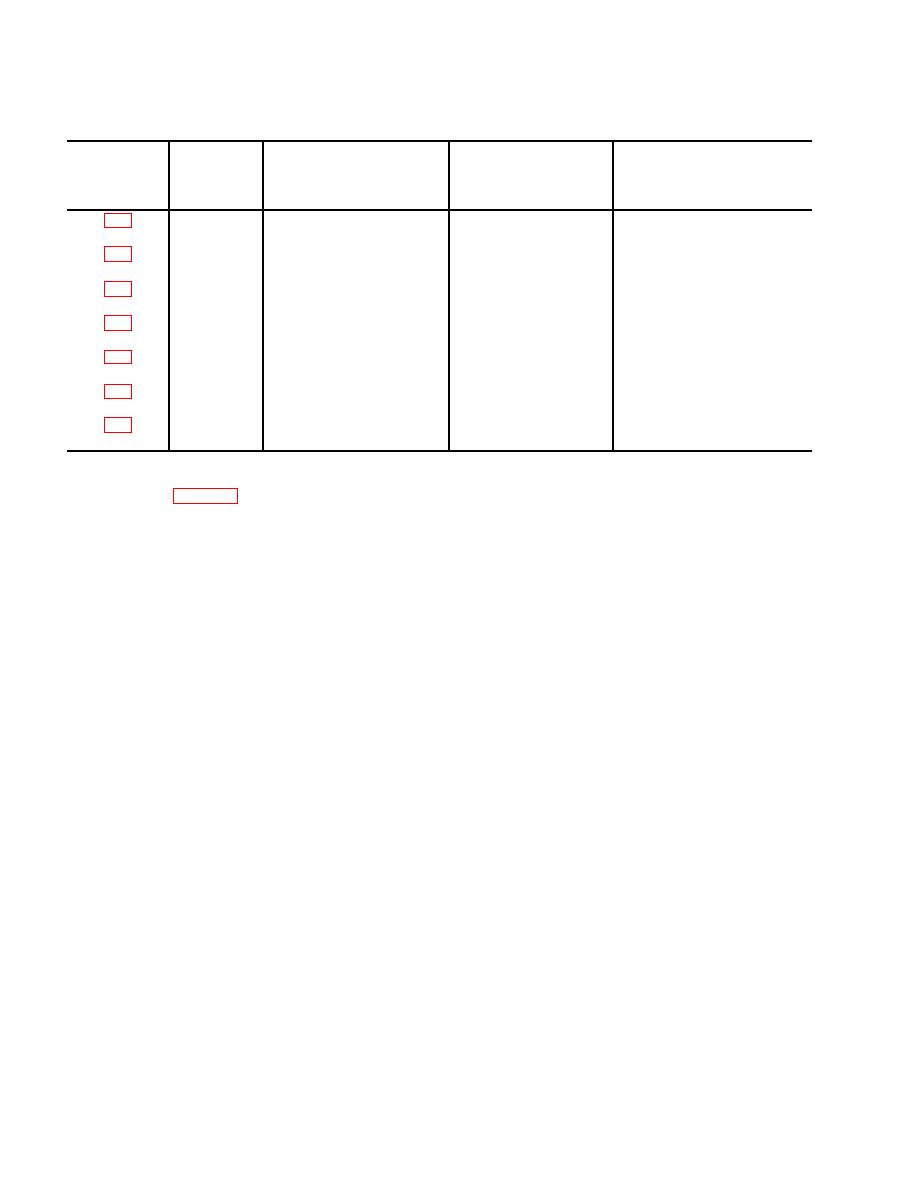

Table 6-2. Repair Standards for Hydraulic Pump Assembly

Ref-

Figure

erence

Points of

Size and Pit

Number

Letter

Measurements

of New Parts

Wear Limits

A

Thickness of wear plate

0.248 to 0.250

0.246

B

Width of gears

2.5000 to 2.5005

2.499

C

OD of gear shaft

0.9990 to 0.9995

0.9980

D

OD of bearing

1.6870 to 1.6875

(e)

E

ID of bearings

1.0000 to 1.0005

(e)

C-E

Fit of shaft in bearing

0.0005L to 0.00015L

(e)

D-F

Fit of bearing in recess

0.000 to 0.OO1T

(e)

NOTE: An asterisk (*) indicates a replacement part only.

g. Install

snapring

(3)

securing

bearing

on

6-7.

Assembly (Fig 6-5).

gearshaft.

a. During assembly, replace with new preformed

h. Install seal (14) and oil seal (2) on gearshaft with

packing, seals, and all worn or damaged parts.

tipad surface of seal facing up.

b. There are four bearings to be installed. All

i. Turn end cover (15) with small opening down,

except the drive gear bearing (4) in the end cover (15)

and install gearshaft (8) into its bore in end cover, and

are installed in the same manner.

secure with snapring (1).

c. Place one bearing (4) at top of each bore, and

j. Position gear (13) so that it will mate with

align carefully with bore.

gearshaft (8) in accordance with dye marks made during

disassembly, and insert gear into its bore in end cover.

d. Press bearing into bore until firmly seated.

k. Place preformed packing (5) on machined

e. Install wear plate (6), removed from end cover

surface of end cover (15).

(15) on drive gear shaft.

l. Lower housing (12) into end cover, position it in

accordance with punch marks made during disassembly.

NOTE

Locate housing over the dowel pins in cover and seat

firmly.

Wear plate can be identified and

properly installed by noting dye marks

made during disassembly.

f. Install remaining bearing (4) on gear shaft.

6-7