in the performance of second-echelon pe-

b. To lubricate the equipment in accord-

riodic services.

ance with paragraph 53.

c. Services. Second-echelon services

are defined by, and restricted to, the fol-

56. Recording Repairs

lowing general procedures unless approval

Repairs accomplished will be in accord-

has been given by the supporting ordnance

ance with the procedures and standards

organization.

prescribed in appropriate technical manu-

(1) Adjust. Make all necessary adjust-

als. The equipment record system pro-

ments in accordance with instruc-

vides for recording repairs required and

t i o n s contained in the pertinent

accomplished on specific items of equip-

section of this technical manual or

ment. This will include, but is not limited

technical bulletin.

to, adjusting, c1eaning, replacing, and

(2) Clean. Clean the unit as outlined

straightening. Deficiencies and shortcom-

in paragraph 43 to remove old lu-

ings not corrected by operators or crew,

bricant, dirt, and other foreign ma-

or those discovered during periodic in-

terial.

spections, will be corrected, insofar as

(3) Tighten. All tightening operations

possible, by second-echelon maintenance

should be performed with sufficient

personnel. These repairs will be indicated

wrench torque to tighten the unit

on DA Form 2404 and recorded on the or-

according to good mechanical

ganizational maintenance record of the

practice. Do not over-tighten, as

equipment log.

t h i s may strip threads or cause

distortion. Tightening will always

57. General Procedures

be understood to include the cor-

r e c t installation of lockwasher,

a. Automatically App1ied. All of the

locknuts, locking wire, or cotter

general procedures given in the operator's

manual will be followed. Organizational

pins, to secure the tightened nut.

mechanics must be so thoroughly trained

in these procedures that they apply them

58. Specific Procedures for Second Echelon

automatically at all times in the perform-

ance of their duties.

to be performed on the vehicle by second-

b. First-echelon Participation. The op-

echelon personnel for each monthly "M"

erator usually accompanies the equipment

service.

and assists the organizational mechanics

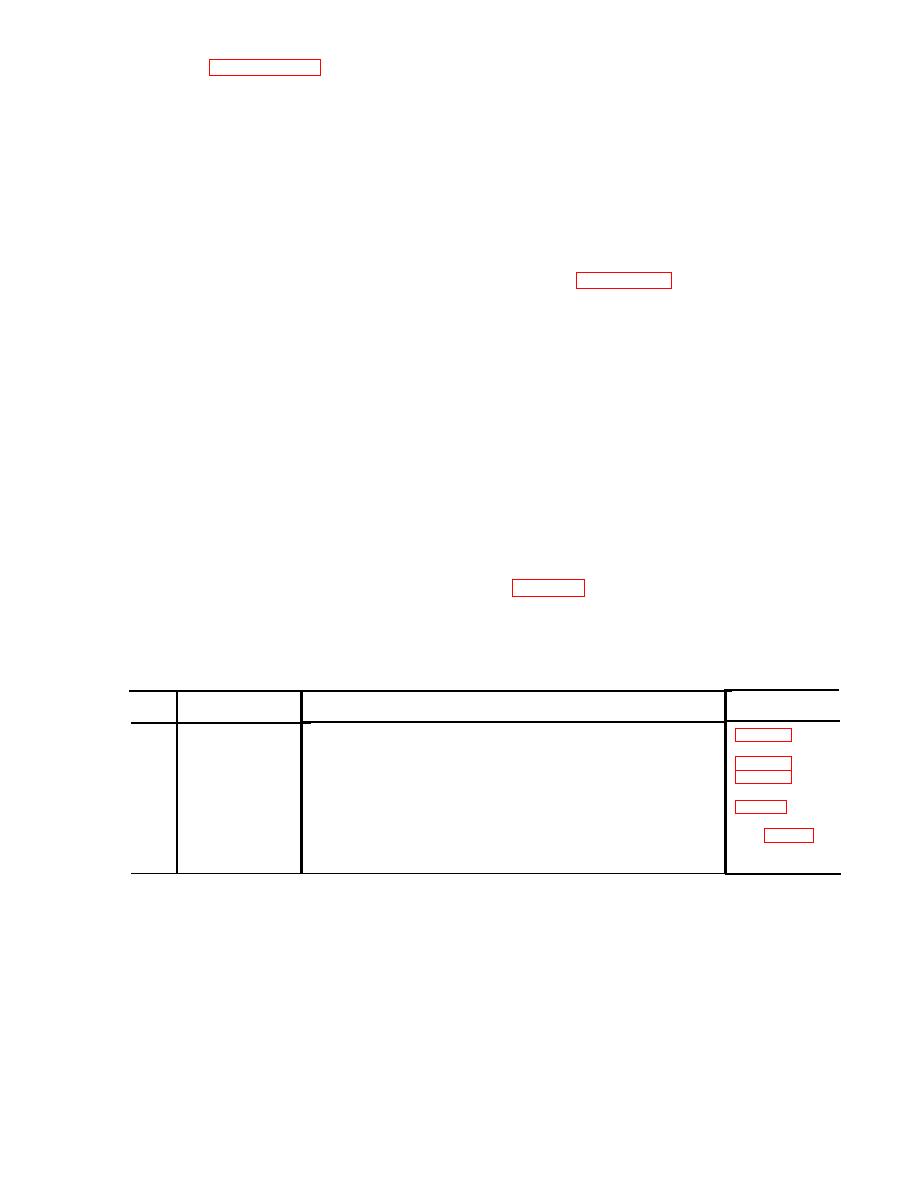

Table 3. Preventive-Maintenance Checks and Services

Monthly Schedule

2nd Echclon

Reference

Sequence

Item to be

Procedure

paragraph

number

inspected

1

Work lamp ----

Check for damaged or frayed wire. Replace unserviceable

incandescent lamp.

Electrical clips

Straighten bent electrical clips or replace as necessary -----

2

3

Electrical cable

Replace cracked or damaged electrical cable nipples --------

nipples.

Par. 24 and

Start the tester, clip the vacuum hose and check to see if

4

Vacuum pump --

32.

vacuum will reach its maximum on vacuum gage.

See par. 54

5

Tester case and

Check for dents and exposed surfaces. Straighten dents,

for painting

control panel.

tighten loose screws, and paint exposed surfaces.

instructions.

Section IV. TROUBLESHOOTING

59. Purpose

components by indications, symptoms, and

tests. Close adherence to the procedures

Troubleshooting is a systematic deter-

covered herein will materially reduce the

mination of malfunctions and defective

23