GRINDING with REFACER ATTACHMENTS

As the preliminary step, a micrometer feed bar

supplied with the attach-

ment must be assembled to the valve refacer at the right side of the wheel-

head (after having first removed the plug in the wheelhead by striking it

sharply with a hammer directly on center - thus causing the plug to become

loose in the hole). The micrometer feed bar

is then inserted into the socket

of the wheelhead casting, turning the flat face of the spindle until it is facing

the set screw for the spindle socket. The spindle is then slid into its socket

until it bottoms; and then fastened in place with the set screw. Be sure that

the spindle collar fits snugly against the bottom of the counterbore in the

wheelhead housing.

DRESSING the ATTACHMENT WHEEL-

Clamp the diamond in the V-way by means of the quick-

clamp.

The flat, recessed side of the wheel is dressed by feed-

ing the diamond forward to contact this face through means

of the nut; and, with wheel running, moving the bracket

back and forth (fast swing for rough, slow swing for smooth

surfaces). The dressing cuts should be about .002''deep

and are controlled by calibrations in thousands of an inch

on the nut. The wheel should be dressed until the entire

face has been trued.

MICROMETER VALVE STEM GRINDING-

Avoids hit or miss grinding - to give this operation the same precision used

in the valve reconditioning work itself, and to save valuable time - use the

which accurately measures

V a l v e Stem Grinding Attachment,

(in thousandths) the amount to be ground from each valve stem, and then just

as accurately measures (in thousandths) the grinding operation itself.

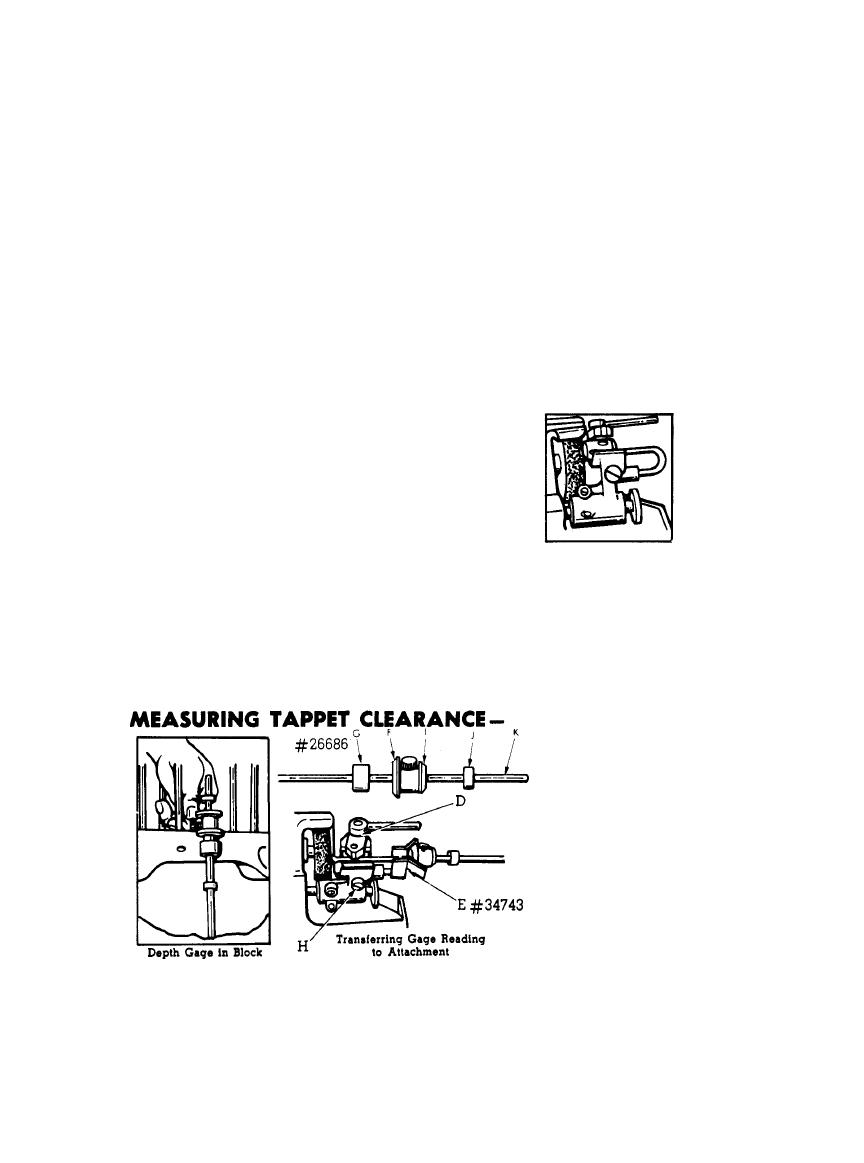

Square tappets be-

fore measuring for

t a p p e t clearance

with Depth Gage

The

universal

depth gage

is

equipped with cor-

rect size valve-head

patterns and bush-

ings for Ford re-

movable guide en-

gines. Valve-head

(F) is for Ford A

and V8-85; bushing

(G) is for Ford V8-85

valve - guide hous-

ing: valve head (I) is for Ford V8-60 valve seat; and bushing (J) is for V8-60

valve-guide housing. The valve-guide bushings are, of course, removed from

10