TM 9-2330-356-14

4-79. Starter Motor

b. Removal (Fig. 4-124).

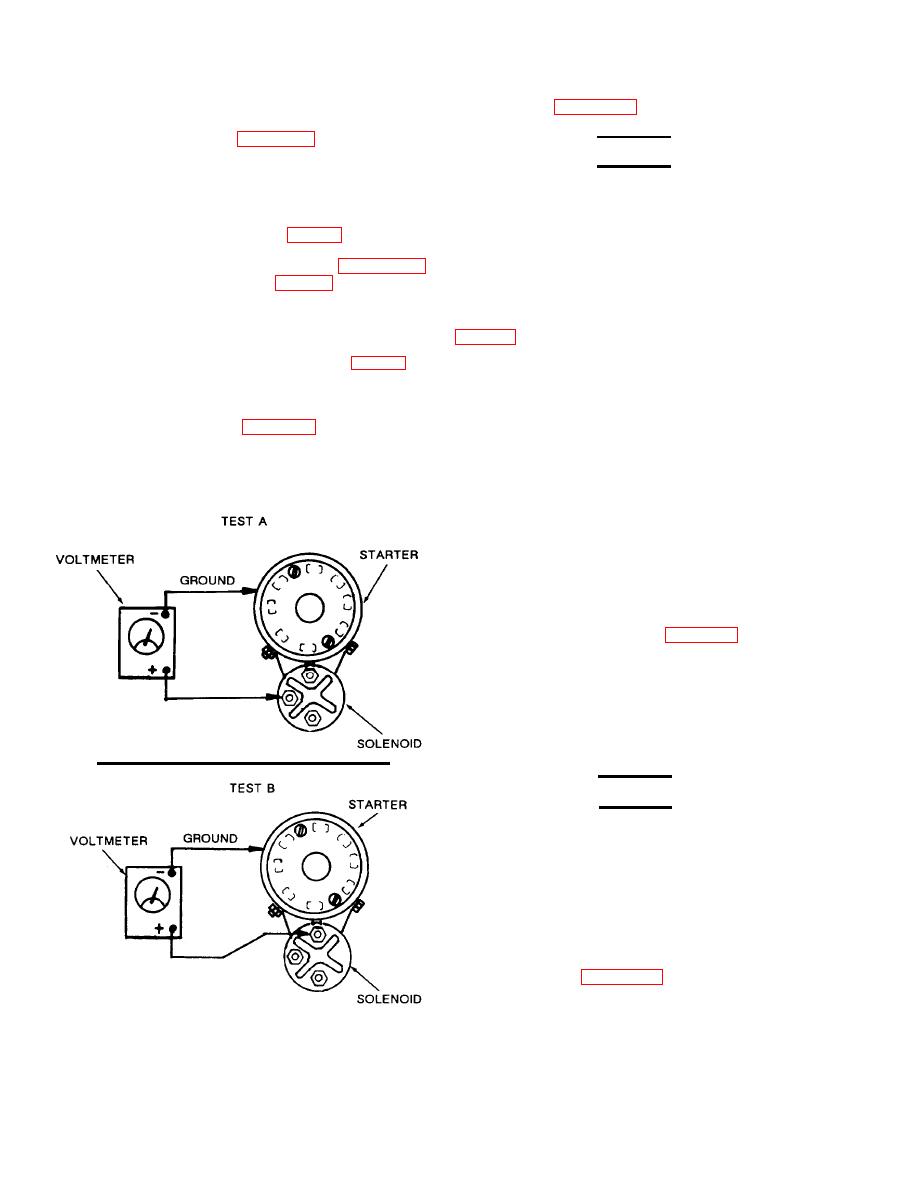

a. Test, On Equipment (Fig. 4-123).

WARNING

(1) Make sure batteries are fully charged and

When performing electrical maintenance,

that all battery and starter cables are serviceable and

ALWAYS disconnect intervehicular electrical

properly installed.

cable from semitrailer, and negative battery

cables at batteries. Failure to follow this

(2) Turn engine switch (2, fig. 2-9) to RUN.

warning may create a spark and explosion,

(3) Connect voltmeter as shown in figure 4-123,

resulting in serious injury or death to

Test A. Turn starter switch (4, fig. 4-9) to START. A

personnel.

voltage reading (12V) indicates circuits leading to starter

are okay.

(1) Remove negative battery cable from battery

(4) Connect a voltmeter as shown in

(2) Starter removal is done from underneath the

START.

vehicle on the left side of the engine.

(a) If no voltage is indicated, solenoid is

(3) Remove starter solenoid protective bracket

defective. Replace solenoid (para 4-80).

(1) by removing two retaining capscrews (2) and washers

(3). Remove five capscrews (4) from engine air shutter.

(b) If voltage is indicated, (12V) but starter

After these screws are removed, the engine air shutter can

does not turn, starter is defective. Replace starter.

be raised to get at top retaining bolt on starter.

(4) Remove hot lead No. 6 from large bottom

pole of solenoid and lead No. 74 from small pole on rear

side of solenoid.

(5) Remove capscrew (5), washer (6), capscrew

(7), external tooth lockwasher (8), and nut (9) from starter

rear support bracket (10). Remove rear starter bracket.

(6) Raise engine shutter (fig. 4-124) so you can

get at top retaining bolt on starter. Remove top capscrew

(11) and washer (12) using a 3/8-inch drive set, long

extension, universal joint, and a 9/16-inch universal

socket. Remove bottom capscrew (13) and washer (14),

then remove starter (15).

c. Installation.

WARNING

When performing electrical maintenance,

ALWAYS disconnect intervehicular electrical

cable on semitrailer, and negative battery

cables at batteries. Failure to follow this

warning may create a spark and explosion,

resulting in serious injury or death to

personnel.

(1) Before installing starter motor, check the

pinion clearance (fig. 4-124). Proper clearance is

important to ensure that starter engages.

TA099853

into full mesh position, then measure the clearance

Figure 4-123. Testing Engine Starter.

between the pinion and pinion stop.